Automatic degassing and pressure regulating device for material box

A kind of material box, automatic technology, applied in the direction of valve device, engine components, gas/liquid distribution and storage, etc., can solve the problems of clogged vents, high cost, difficult to popularize, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

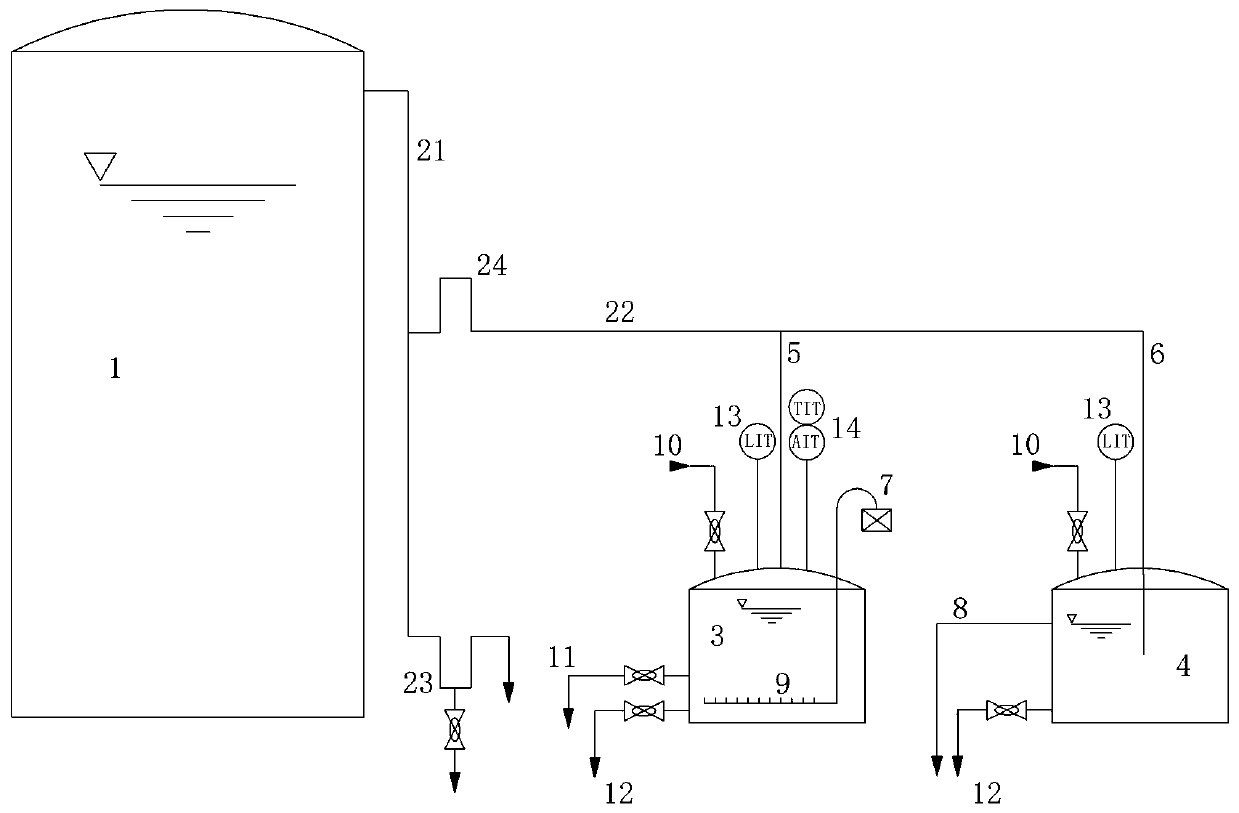

[0015] Embodiment one, such as figure 1 Shown; the material box is filled with liquid materials, such as demineralized water.

[0016] An automatic degassing and pressure regulating device for a material box, including a material box 1 for storing liquid materials, and a regulating pipe is installed at the vent on the material box; there is also a degasser for chemical liquid materials that can absorb specific gases (such as carbon dioxide) The air box 3, and the water-sealed box 4 filled with liquid, the degassing box and the water-sealed box are respectively connected to the regulating pipe through the suction pipe 5 and the exhalation pipe 6, and the end of the exhalation pipe extends to the liquid level in the water-sealed box Below; the air intake pipe 7 for gas inflow is also installed on the degassing box, the air intake pipe is connected to the liquid level below in the degassing box, and the discharge pipe 8 for discharging excess liquid is housed on the water seal bo...

Embodiment 2

[0030] Embodiment two, such as figure 2 shown; the material box is filled with solid materials.

[0031]An automatic degassing and pressure regulating device for a material box, including a material box 1 for storing solid or pasty materials, and a discharge pipe 8 is an exhaust pipe, which is connected to the water seal box 4 above the liquid level of the water seal box; the rest are related to the implementation Example 1 is the same.

[0032] The automatic degassing and pressure regulating device for the material box, when the material box is under positive pressure, the excess gas will be discharged through the water seal box and the exhaust pipe, thereby realizing the air pressure adjustment in the material box.

Embodiment 3

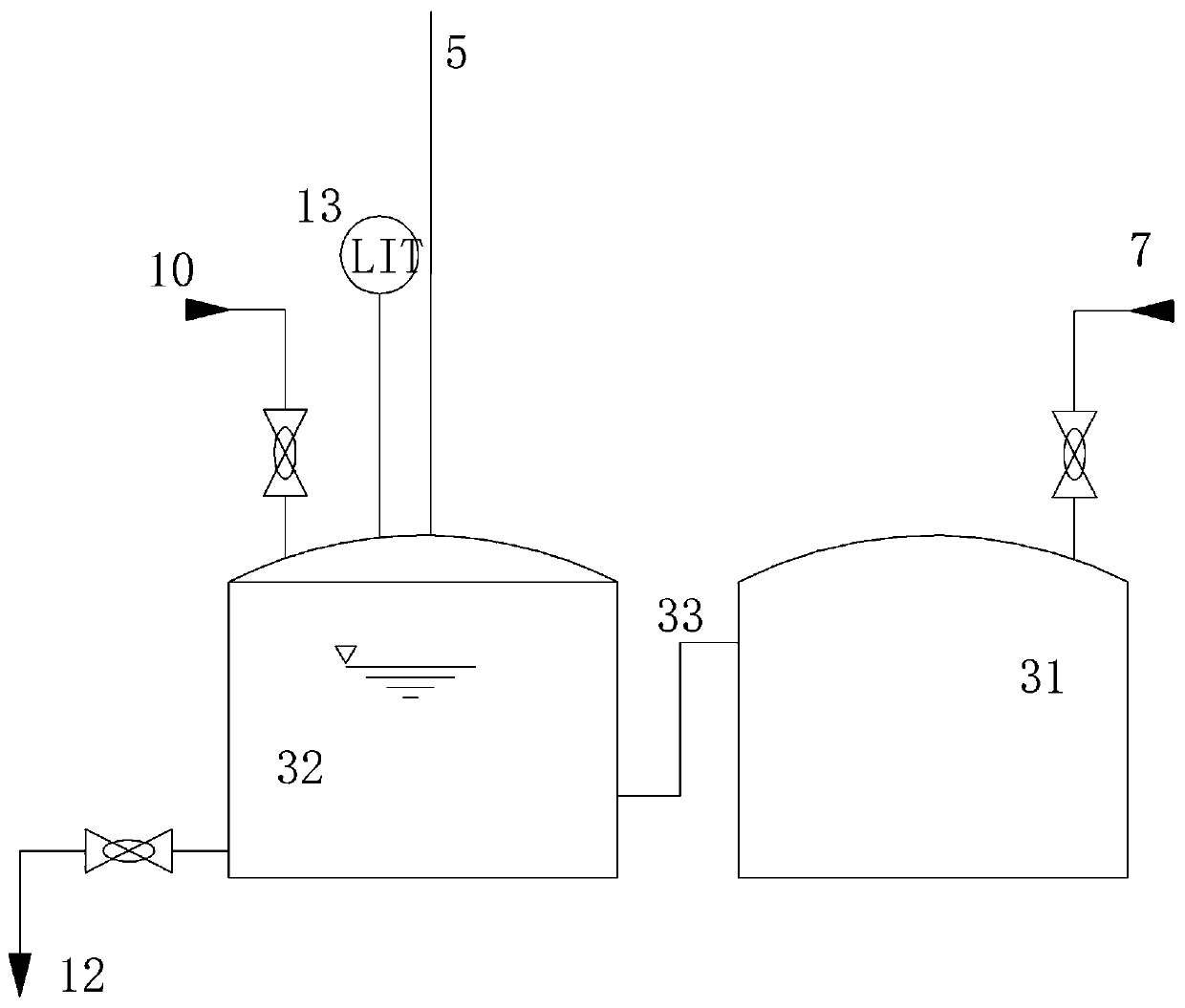

[0033] Embodiment three, such as image 3 Shown; The specific gas in the air is absorbed by the solid material in the degassing box.

[0034] An automatic degassing and pressure regulating device for a material box, comprising a material box 1 for storing materials, a filter cabin 31 with chemical materials capable of absorbing specific gases and a liquid cabin 32 with liquids, the filter cabin and The liquid tank is communicated by the connecting pipe 33, and the connection between the connecting pipe and the liquid tank is located below the liquid level in the liquid tank; the liquid inlet pipe 10, the drain pipe 12 and the liquid level gauge 13 are installed on the liquid tank 32 respectively, and the filter cabin 31 is equipped with a refueling port for changing chemical materials; the rest are the same as in embodiment one or embodiment two.

[0035] The air enters the filter chamber from the intake pipe and reacts with the chemical materials in it, and the filtered gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com