Method for forming battery shell inlaid with metal part and battery shell

A technology of battery casing and molding method, which is applied to small-sized batteries/battery packs, large-sized batteries/battery packs, battery boxes/jackets, etc., can solve problems such as insufficient connection, falling off of metal parts, safety accidents, etc. To achieve the effect of good connection, ensure flatness, and avoid safety problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

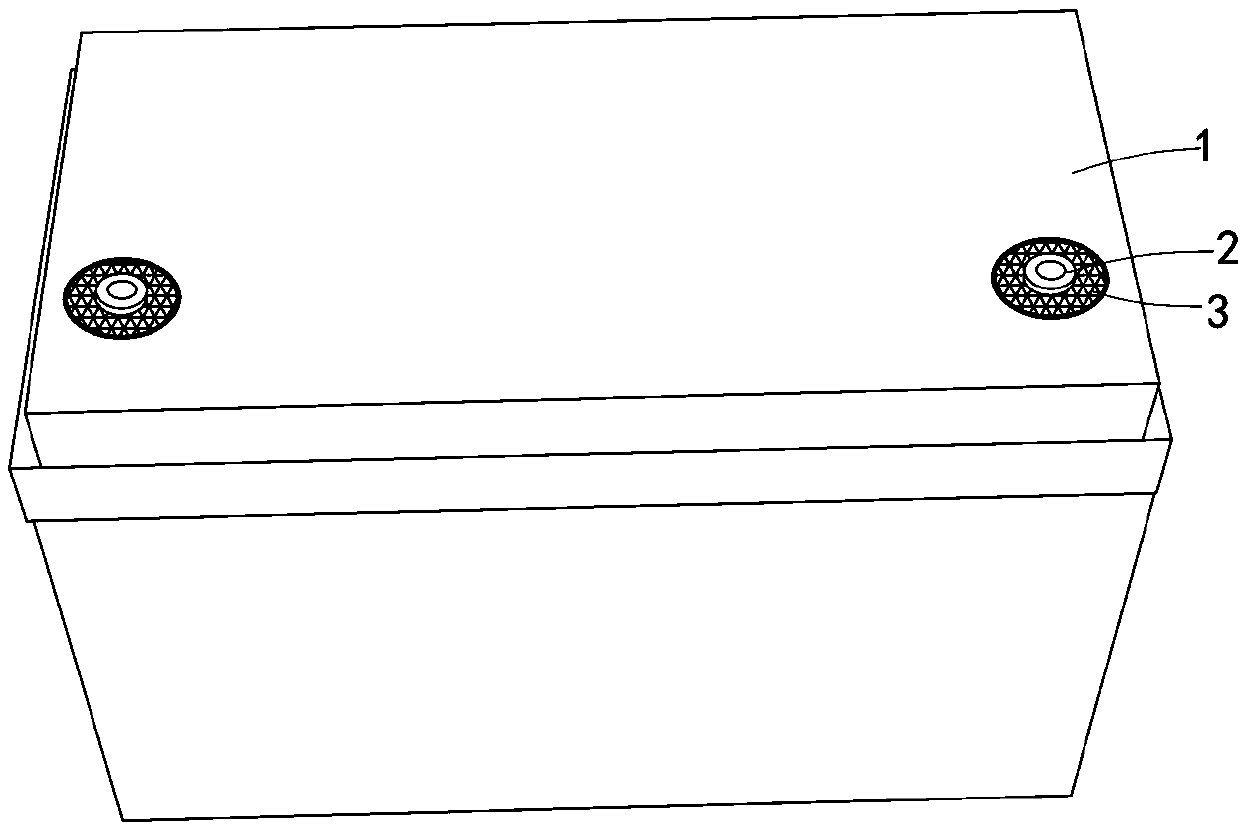

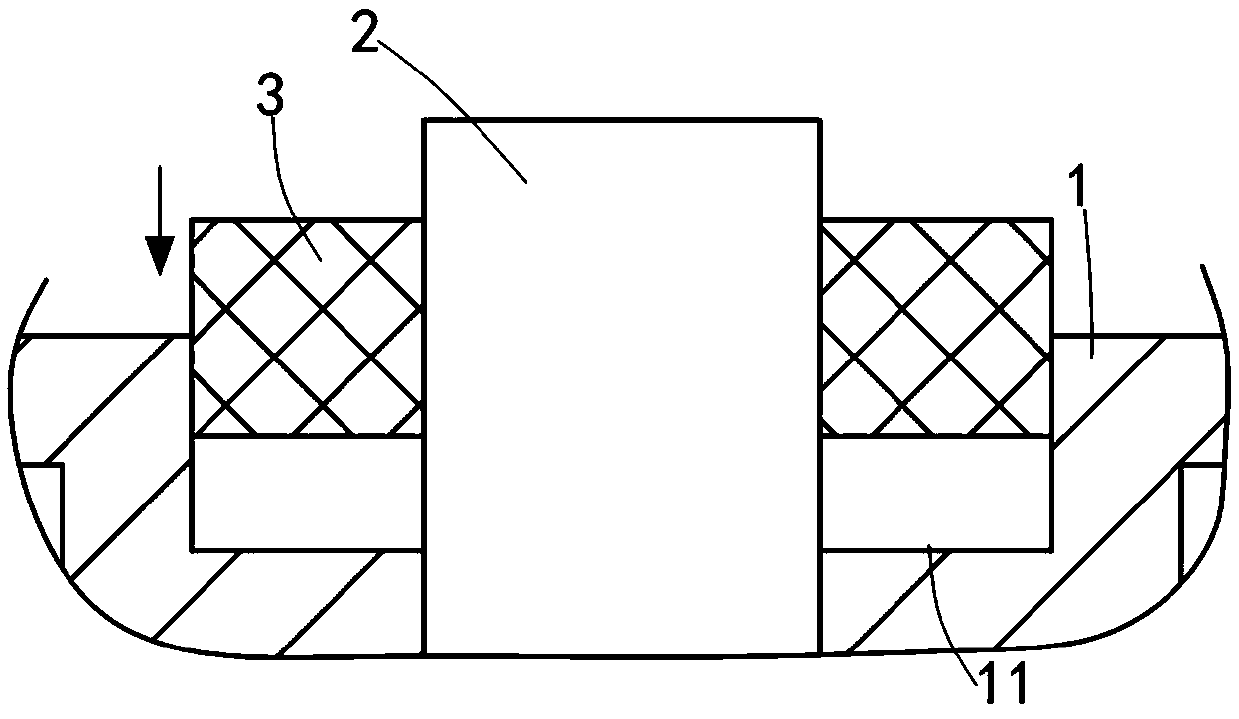

[0036] A method for forming a battery casing embedded with metal parts provided by the present invention includes: providing the metal parts, and pretreating the metal parts; After closing the mold with the fixed mold, the injection molding raw materials are injected into the mold to combine the metal parts and the plastic; after cooling and demoulding, the injection molded products combined with the metal parts and the plastic are obtained, and finally the injection molded products are inspected to screen out qualified products and defective products .

[0037] A plurality of connection grooves are evenly distributed on the side wall of the metal part, and the connection grooves can allow injection molding raw materials to flow in, thereby enhancing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com