Rare earth-doped multi-core optical fiber, optical fiber preform rod, preparation method and application thereof

A fiber preform, multi-core fiber technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as deterioration, fiber damage beam quality, nonlinear effects, etc., achieve large mode field area, increase transmission power, and excellent beam quality quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] In a second aspect, an embodiment of the present invention provides a method for preparing a rare earth-doped multi-core optical fiber preform, comprising the following steps:

[0066] (1) Deposit M rare-earth-doped mandrels in a liner made of pure silica material, so that the relative refractive index difference of M-1 preformed rods is Δ2 and the diameter is d 2 , and Δ2 and d 2 The relationship that needs to be satisfied is:

[0067] The relative refractive index difference of the remaining one core layer is Δ1, and the diameter is d 1 , and Δ1 and d 1 The relationship that needs to be satisfied is:

[0068] (2) The M core rods obtained in the step (1) are matched with sleeves of pure silica material and fused into M solid rods;

[0069] (3) The solid rod obtained in step (2) is ground into a regular hexagonal rod, and its side-side distance is l, wherein, l and d 1 、d 2 The relationship that needs to be satisfied is:

[0070] (4) Prepare the sleeve pipe...

Embodiment 1

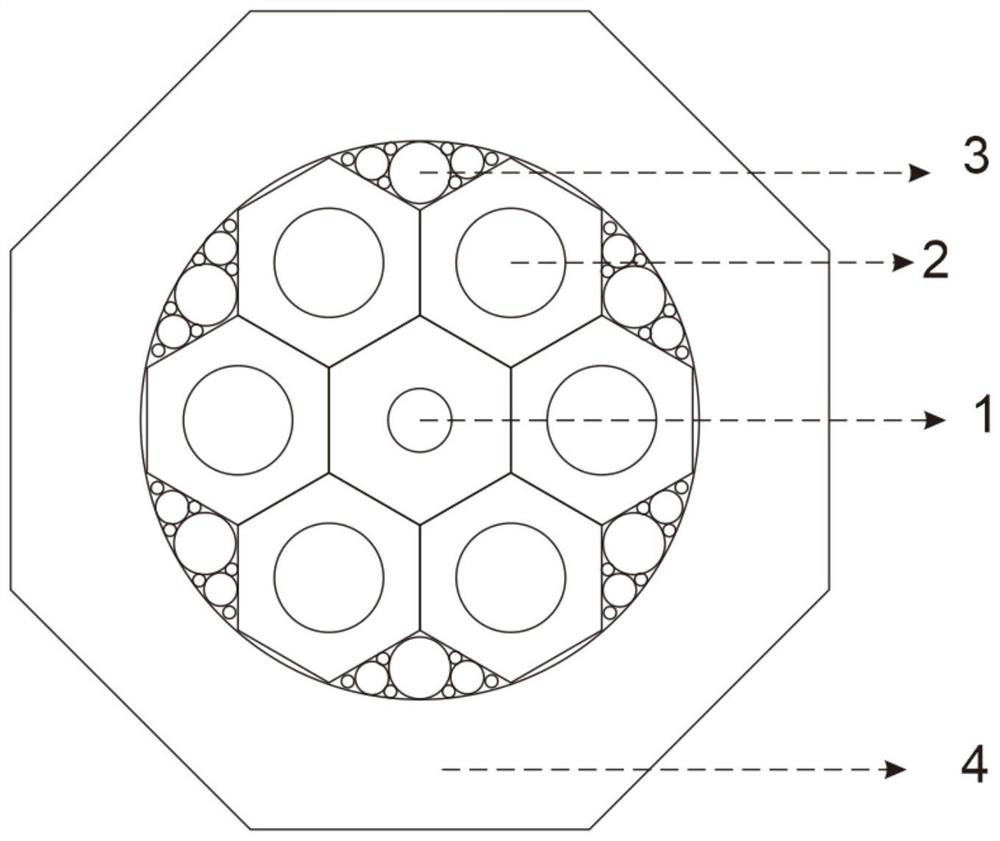

[0095] A rare earth-doped multi-core optical fiber preform, such as figure 1 As shown, it includes a preform 1 for forming the core, a preform 2 for forming the rest of the core except the intermediate core, a glass sleeve 3 for forming the cladding, and a glass filament 4 for filling the gap; , a total of 7 prefabricated rods used to form the core, each of which is composed of a Yb-doped core region and a pure silica cladding, and the core relative refractive index difference Δ1 of the preformed rods constituting the intermediate core is 0.12% , the diameter is 2.5mm, the material of the cladding is pure silica, the shape is a regular hexagon, and its side-side distance is 3.6mm; the core relative refractive index difference Δ2 of the prefabricated rods constituting the surrounding 6 cores is 0.07 %, the diameter is 3mm, the material of the cladding is pure silica, the shape is a regular hexagon, and its side-side distance is 3.6mm;

[0096]A glass sleeve used to form the cl...

Embodiment 2

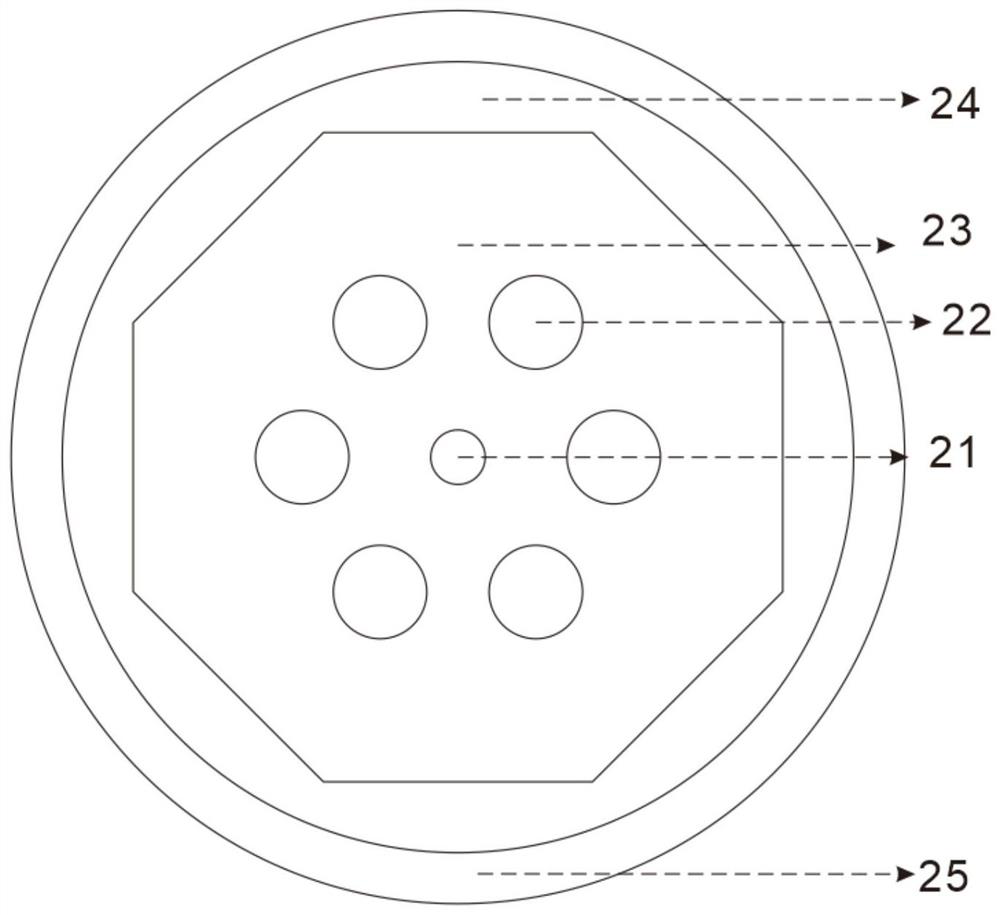

[0113] A rare earth-doped multi-core optical fiber preform, such as Figure 5 As shown, it includes a preform 1 for forming the intermediate core, a preform 2 for forming the rest of the core except the intermediate core, a glass filament 3 for filling the gap, and a glass sleeve 4 for forming the cladding; A total of 19 prefabricated rods are used to form the core, each of which is composed of a Tm-doped core region and a pure silica cladding. The core relative refractive index difference Δ1 of the preformed rods constituting the intermediate core is 0.13%, The diameter is 4mm, the material of the cladding is pure silica, the shape is a regular hexagon, and its side-side distance is 6mm; the core relative refractive index difference Δ2 of the prefabricated rods constituting the surrounding 18 cores is 0.085%, and the diameter 4mm, the material of the cladding is pure silica, the shape is a regular hexagon, and its side-side distance is 6mm;

[0114] A glass sleeve used to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com