Aluminum foil for electronic tag with low pinholes and high finish degree, and production process thereof

A high-gloss, electronic label technology, applied in the direction of furnace types, manufacturing tools, metal processing equipment, etc., can solve problems such as poor surface finish, large number of pinholes, unreasonable rolling process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

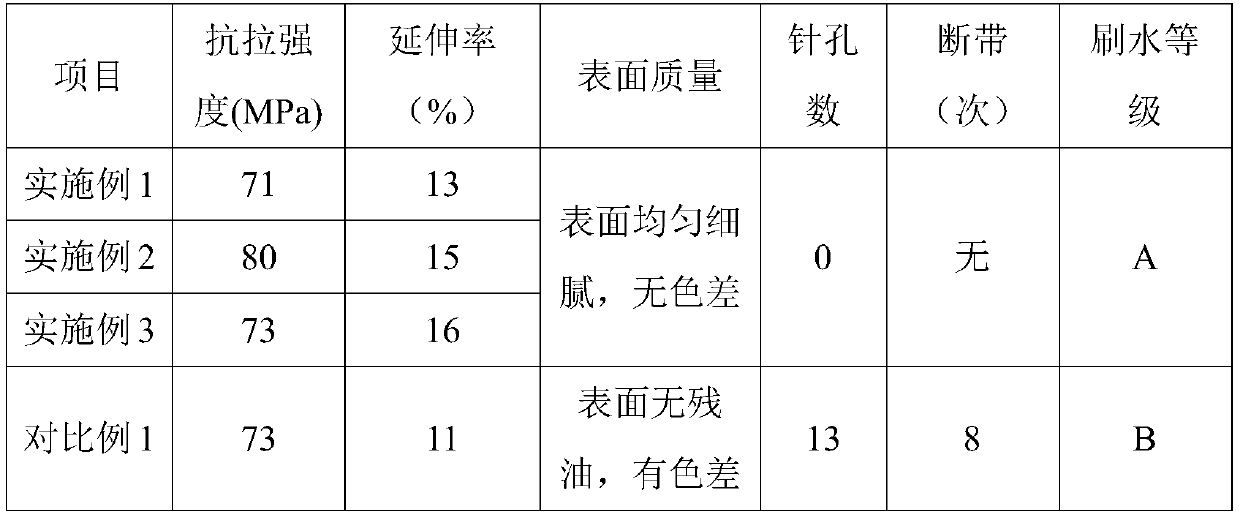

Examples

Embodiment 1

[0033] An aluminum foil for an electronic label with low pinholes and high smoothness, comprising the following raw materials in weight percentage:

[0034] Si: 0.2%, Cu: 0.0.4%, Zn: 0.1%, Mn: 0.09%, Ti: 0.06%, Fe: 0.6%, Ni: 0.055%, Cr: 0.0055%, Cd: 0.007%, Pb: 0.0055 %, Sn: 0.007%, Zr: 0.007%, the remainder is Al, and the weight percent relationship of Fe and Si is: Fe / Si=3, Fe+Si=0.8%.

[0035] A production process of aluminum foil for electronic labels with low pinholes and high smoothness, comprising the following steps:

[0036] S1. Melting: Prepare materials according to the ratio of raw materials, put them into the melting furnace for melting, and the melting temperature is 700-720°C; after the melting starts, pass inert gas into the melting furnace for 100 minutes, and keep it warm for 1 hour;

[0037] S2. Refining: Send the smelted melt into a static furnace for downturning. After the downturning is completed, perform multiple refinements. During refining, adjust the...

Embodiment 2

[0044] An aluminum foil for an electronic label with low pinholes and high smoothness, comprising the following raw materials in weight percentage:

[0045] Si: 0.3%, Cu: 0.06%, Zn: 0.15%, Mn: 0.10%, Ti: 0.10%, Fe: 0.6%, Ni: 0.06%, Cr: 0.006%, Cd: 0.008%, Pb: 0.006%, Sn: 0.006%, Zr: 0.008%, the rest is Al, and the weight percentage relation of Fe and Si is: Fe / Si=2, Fe+Si=0.9%.

[0046] A production process of aluminum foil for electronic labels with low pinholes and high smoothness, comprising the following steps:

[0047] S1. Melting: Prepare materials according to the ratio of raw materials, put them into the melting furnace for melting, and the melting temperature is 700-720°C; after the melting starts, pass inert gas into the melting furnace for 120 minutes, and keep warm for 1 hour;

[0048] S2. Refining: Send the smelted melt into a static furnace for downturning. After the downturning is completed, perform multiple refinements. During refining, adjust the pressure of ...

Embodiment 3

[0055] An aluminum foil for an electronic label with low pinholes and high smoothness, comprising the following raw materials in weight percentage:

[0056] Si: 0.2%, Cu: 0.0.3%, Zn: 0.05%, Mn: 0.08%, Ti: 0.05%, Fe: 0.5%, Ni: 0.05%, Cr: 0.005%, Cd: 0.006%, Pb: 0.005 %, Sn: 0.006%, Zr: 0.006%, the remainder is Al, and the weight percent relationship of Fe and Si is: Fe / Si=2, Fe+Si=0.7%.

[0057] A production process of aluminum foil for electronic labels with low pinholes and high smoothness, comprising the following steps:

[0058] S1. Melting: Prepare materials according to the ratio of raw materials, put them into the melting furnace for melting, and the melting temperature is 700-720°C; after the melting starts, pass inert gas into the melting furnace for 90 minutes, and keep it warm for 1 hour;

[0059] S2. Refining: Send the smelted melt into a static furnace for downturning. After the downturning is completed, perform multiple refinements. During refining, adjust the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com