An improved infinite chilled alloy cast iron steel roll casting method

An infinitely chilled, alloyed cast iron technology, applied in the field of roll manufacturing, can solve the problems of low alloy content, roll graphite, coarse carbide, slow molten iron cooling speed, etc., to achieve high wear resistance and thermal crack resistance, carbide Uniformity and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

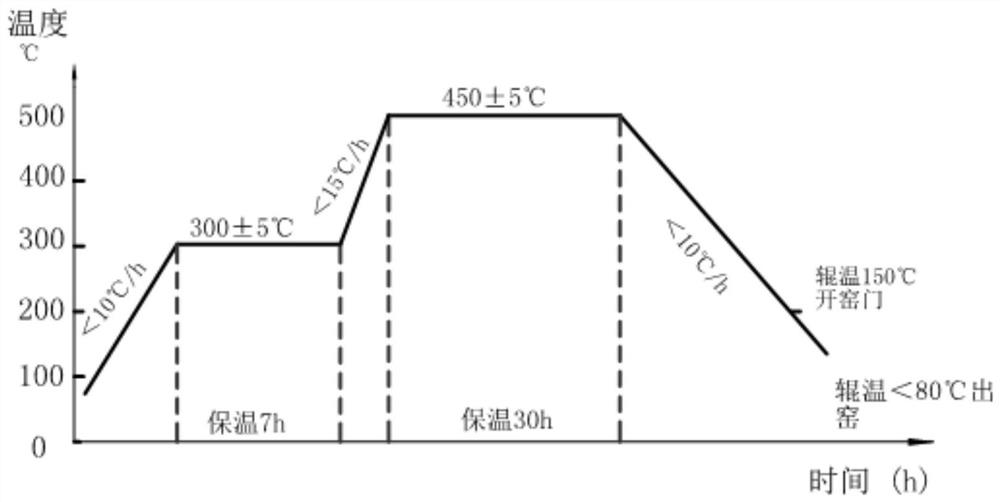

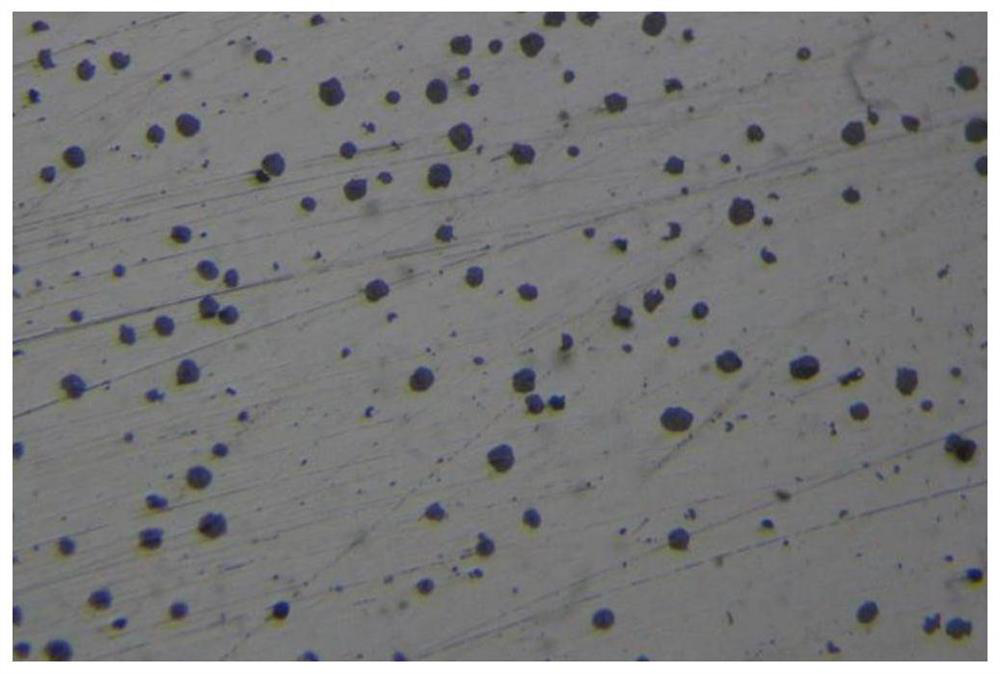

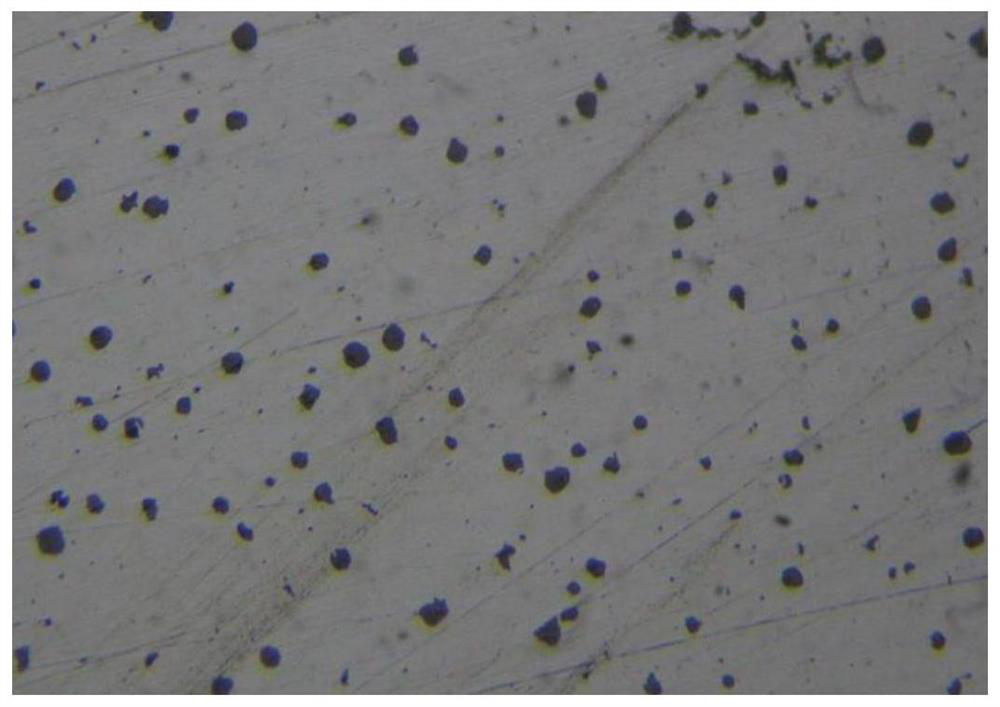

[0025] A method for casting an improved infinitely chilled alloy cast iron shaped steel roll according to the present invention, comprising:

[0026] 1) The chemical composition of cast iron steel rolls is calculated by weight percentage: C 3.00% ~ 3.50%, Si 1.05% ~ 1.65%, Mn 0.40% ~ 0.80%, P < 0.10%, S < 0.03%, Ni 1.50% ~ 2.00 %, Cr 0.25%~0.65%, Mo 0.25%~0.65%; the rest is Fe and unavoidable impurities;

[0027] 2) Before pouring, the molten iron is spheroidized once and inoculated three times to obtain a finely dispersed carbide structure; the details are as follows:

[0028] When the molten iron comes out of the furnace, first add silicon barium inoculant of 0.1% to 0.6% of the weight of the molten iron at the bottom of the sealed bag, react for 1 to 10 minutes, remove the molten iron slag, and perform pressure-added magnesium spheroidization treatment. 0.05% to 0.15%; add magnesium under pressure for 8 to 15 minutes, remove the molten iron slag, add 0.1% to 0.6% of the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com