Intelligent speed reducer

A reducer and intelligent technology, applied in mechanical equipment, measuring devices, instruments, etc., can solve the problems of increased inspection difficulty, delayed production process, and the inability of the reducer to detect working conditions, so as to reduce maintenance downtime and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

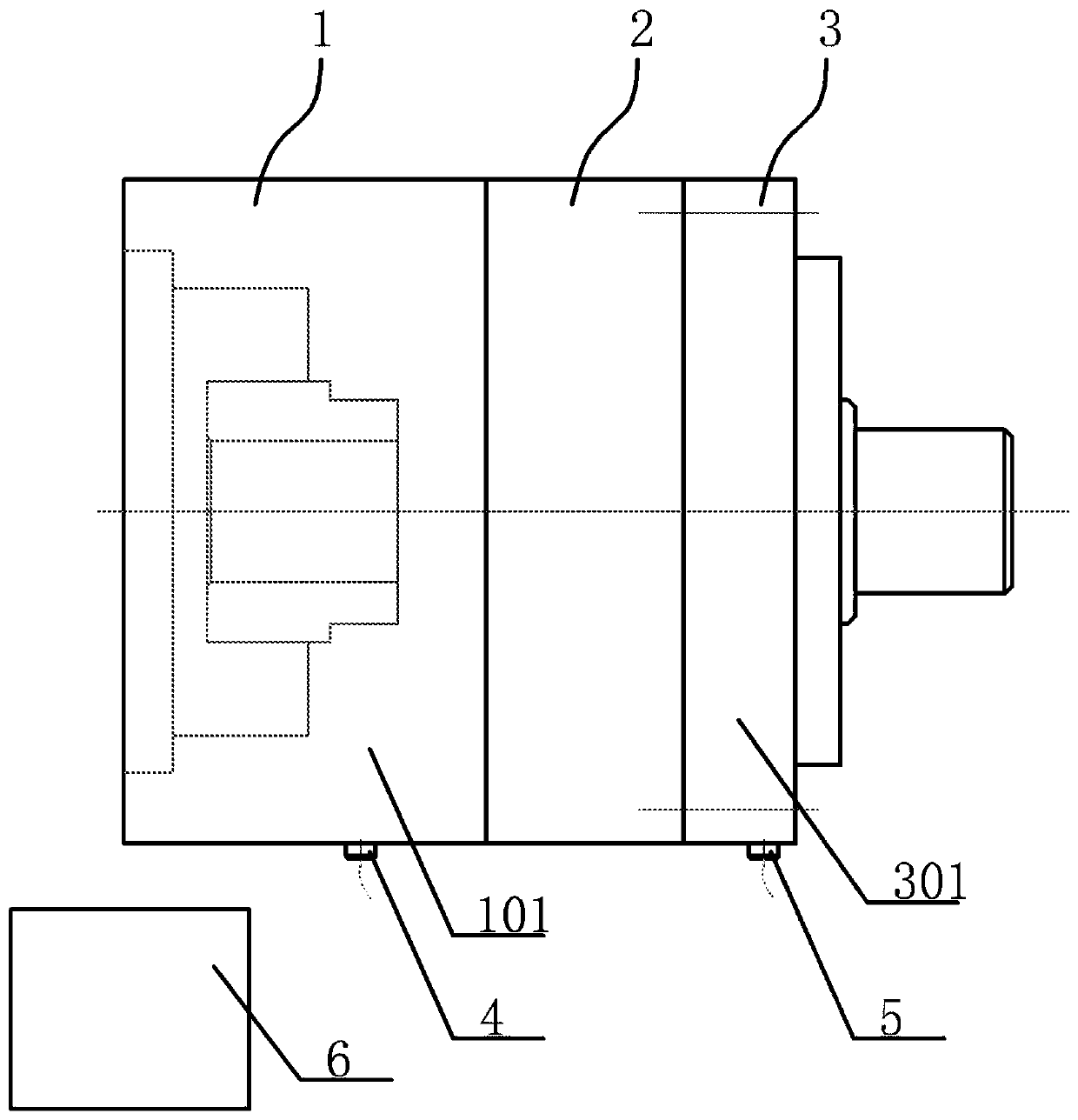

[0016] An intelligent reducer, see figure 1 : It includes an input end assembly 1, an intermediate transmission part 2, and an output end assembly 3. The input end assembly 1 is provided with a first sensor group corresponding to the connection position of each component, and the first sensor group receives corresponding parameters of vibration, torque, and force The output end assembly 3 is provided with a second sensor group corresponding to the connection position of each component, and the first sensor group receives the corresponding parameters of vibration, torque, and force; the input end assembly 1 and the output end assembly 3 are all provided with a grating, and the grating It is used to analyze the angle difference between the input and output rotation of the reducer, and to detect transmission errors and differential stability; the outer casing 101 of the input end assembly 1 is also provided with a first signal receiver 4, the first signal receiver 4 It is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com