Modular electric heating system for radiant floor heating

A modular, electric heating technology, applied in the fields of power supply, floor heating, off-peak power storage systems, and electric heaters, it can solve the problems of high thermal cost, high operating cost, high energy consumption such as power supply, and outdated operating mode. , to achieve the effect of simplifying the paving process, improving the heating efficiency and saving the heating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

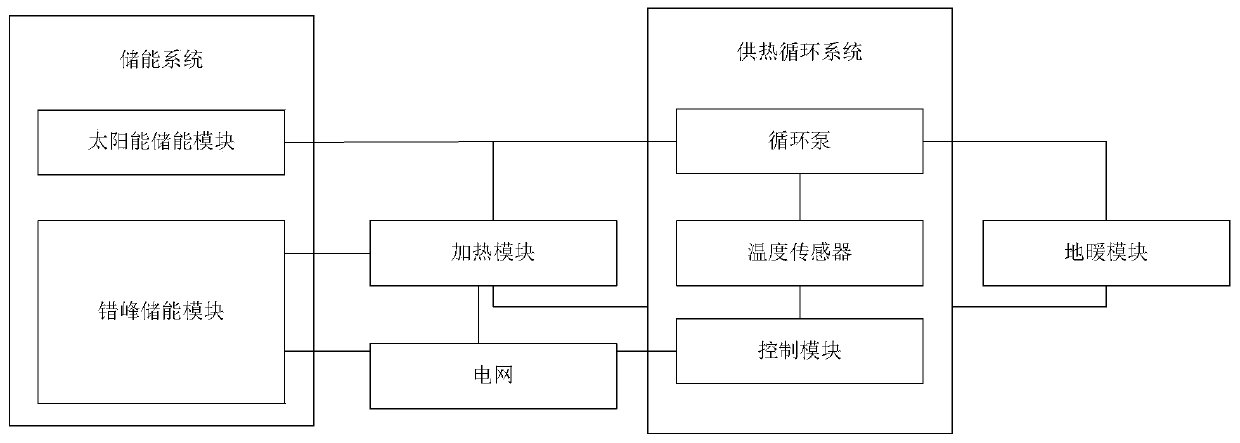

[0027] Such as Figure 1-4 Shown:

[0028] A modular electric heating system for floor heating, including a heat transfer medium, a heating module 1, a floor heating module 7, and a heating cycle system. The heating cycle system includes a control module, a remote communication module, a temperature sensor, a solenoid valve, a circulation pump, A circulation pipeline, wherein: the heating module 1, the floor heating module 7 and the circulation pump are connected to each other through a circulation pipeline to form a heating circuit; the heating module 1 is used to store or heat the heat transfer medium in the heating circuit; The circulation pump is used to provide power for the heat transfer medium, and push the heat transfer medium to flow in the heating circuit; the floor heating module 7 is used to absorb the heat transported by the heat transfer medium, and The heat radiates above the ground; the solenoid valve is used to adjust the direction, flow, and speed of the hea...

Embodiment 2

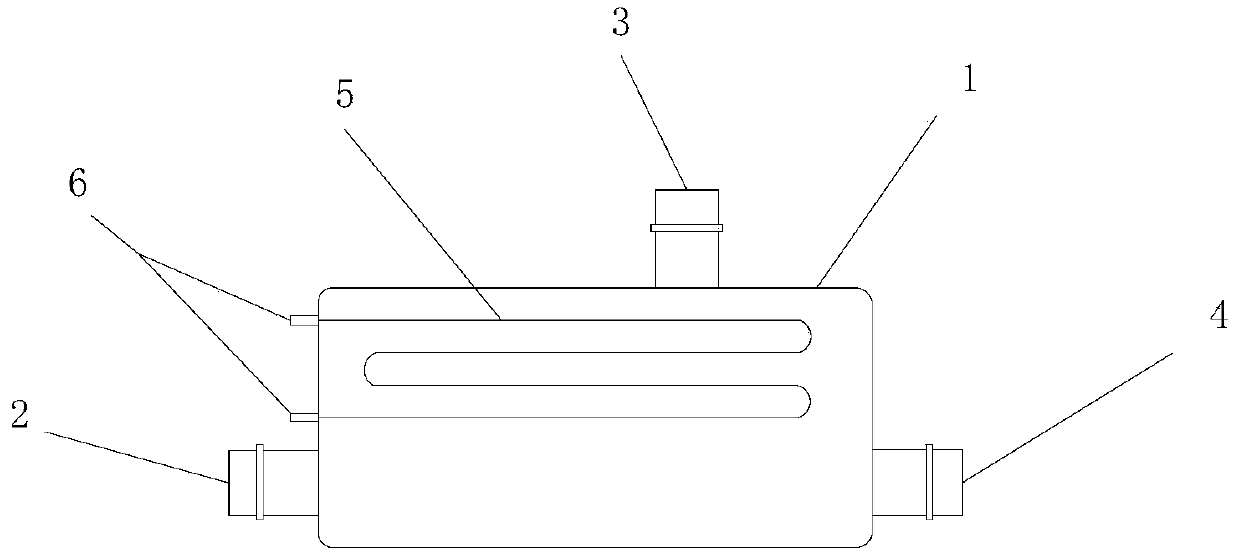

[0041] Such as figure 2 Shown:

[0042] The shown heating module 1 includes a water inlet 2, a longitudinal water outlet 3, a horizontal water outlet 4, a heating wire 5 and a connecting terminal 6, the connecting terminal 6 is provided with positive and negative poles, and the heating wire 5 is connected to the connecting terminal 6 Electrically connected, the heating wire 5 is arranged inside the heating module 1, and the water inlet 2, the longitudinal water outlet 3 and the horizontal water outlet 4 are respectively arranged on the surface of the heating module 1 and connected to the inside of the heating module 1. connected.

Embodiment 3

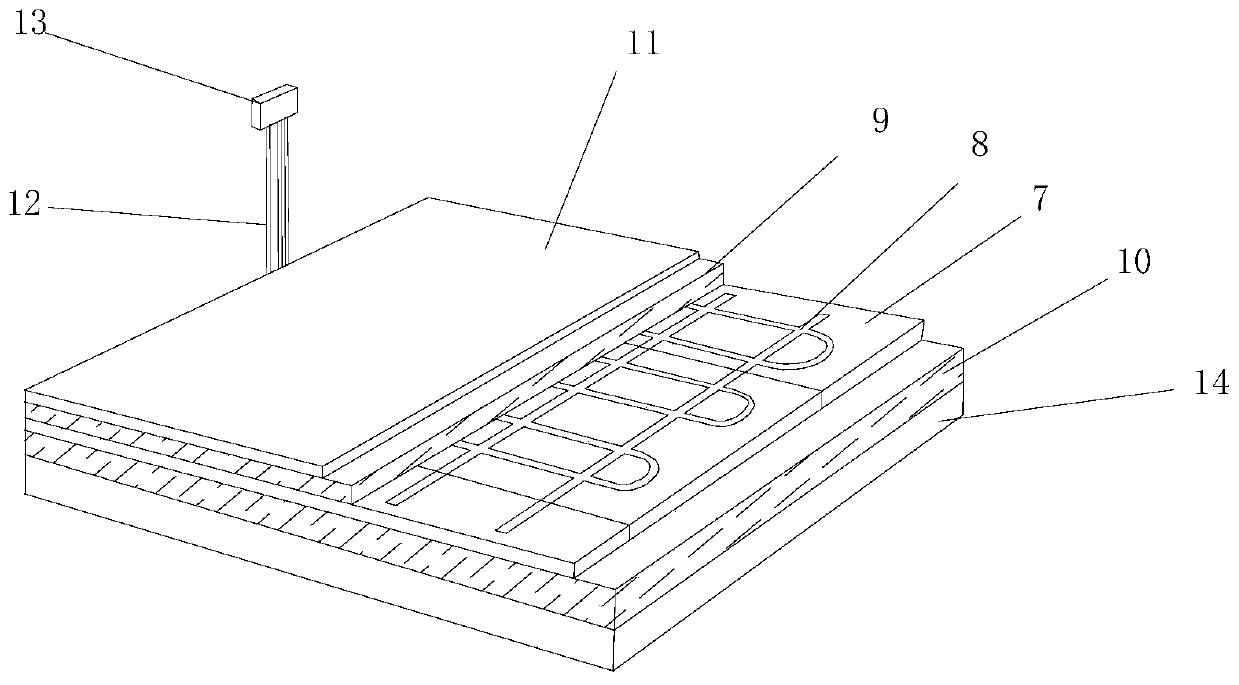

[0044] Such as Figure 5 Shown:

[0045] In the distributed arrangement of multiple rooms in the present invention, the grid represents a number of floor heating modules 7 in different rooms, which are provided with heat through the heating modules 1 connected in series on the circulation pipeline, and each room does not interfere with each other.

[0046] In this embodiment, the control modules and temperature sensors in the heating cycle system are integrated into a temperature controller, the heating module 1 uses several electric heating modules, the floor heating module 7 uses several heat dissipation floors, and includes several electromagnetic valve:

[0047] The power of the electric heating modules used is large, medium and small. According to the area of each room, the number of large, medium and small electric heating modules is different. A 300W to 500W electric heating module supplies 5 to 8 square meters. For example: the living room is zone 1 (including seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com