Power cycle test device and system for semiconductor device

A power cycle and test device technology, applied in the field of power cycle test devices and systems, can solve the problems that the control of junction temperature and case temperature does not meet the experimental requirements, the test device is easy to age, and the cost is high, so as to achieve long service life and high reliability , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

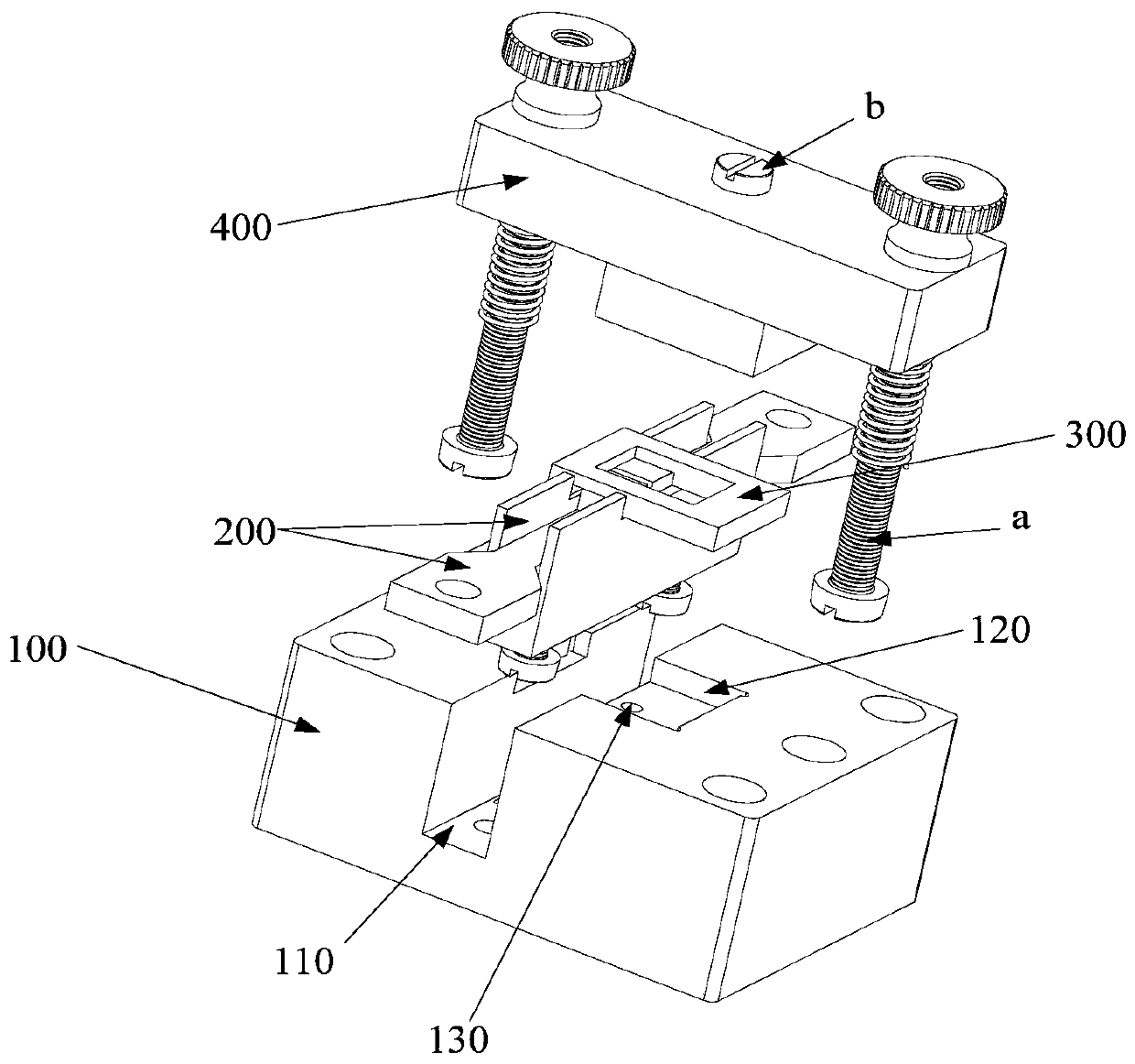

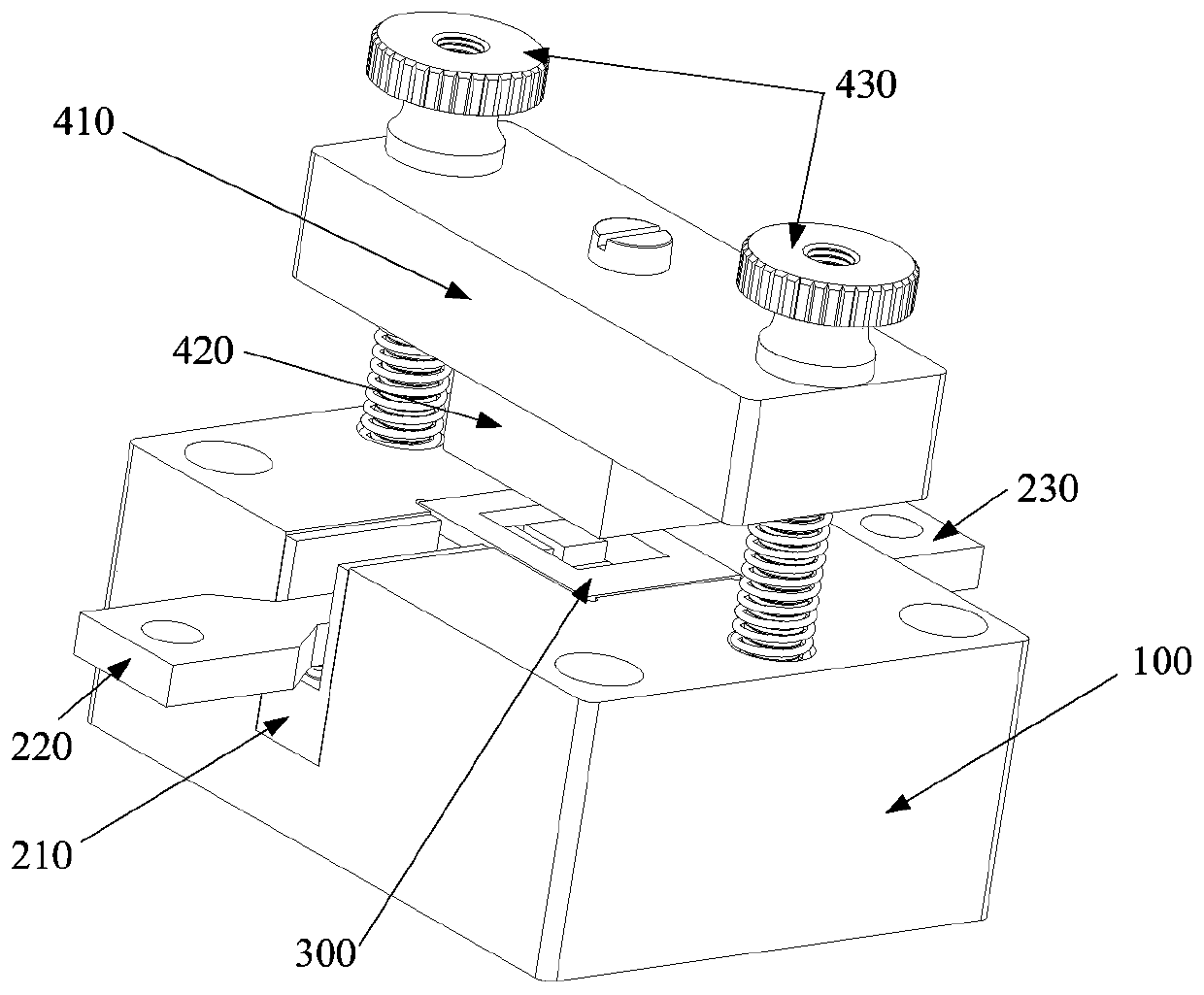

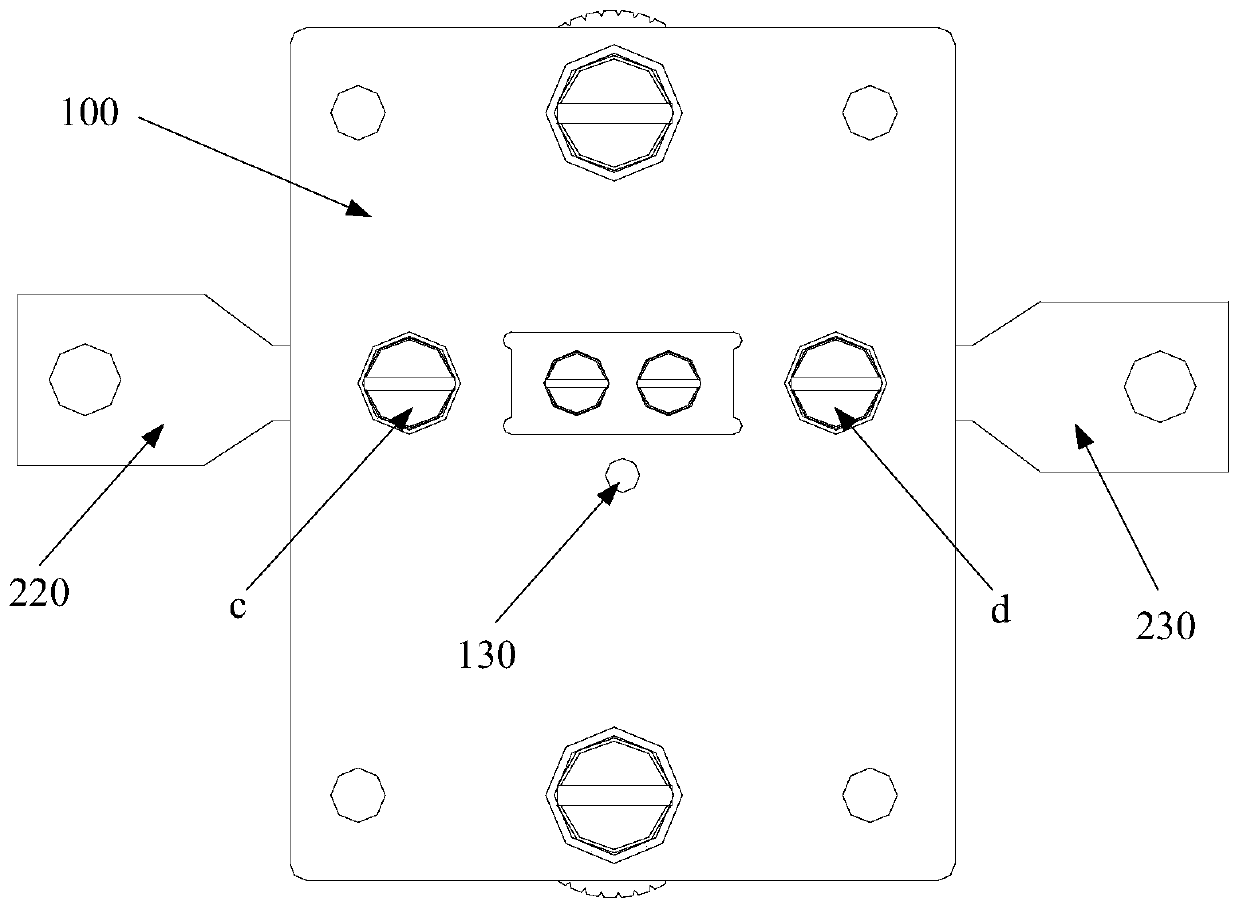

[0049] see figure 1 A power cycle test device for a semiconductor device provided in an embodiment of the present invention is used for reliability tests of power electronic devices, and mainly supports power cycle tests of SMD (Surface Mounted Devices, surface mount) packaged high-power power electronic devices, It is suitable for semiconductor devices with high current and high power above 200A, such as power diodes, MOS tubes, IGBTs, etc.

[0050] The device mainly includes: base 100, electrode equipment 200, device positioning frame 300, elastic briquetting eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com