Integral fully-sealed prefabricated electrical circuit board and manufacturing method thereof

A fully-sealed, prefabricated technology, applied in circuits, electrical components, boards/panels/desks of substations/switchgears, etc., can solve problems such as difficult quality assurance, low production efficiency, and fire retention, and achieve electrical reliability. The effect of improvement, improved anti-vibration performance, and reduced contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

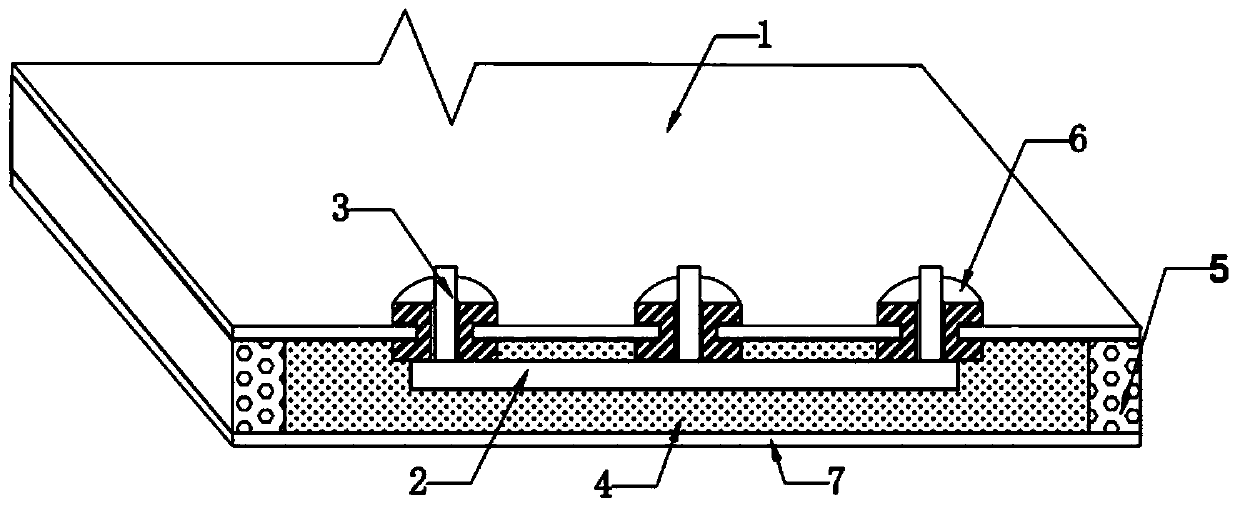

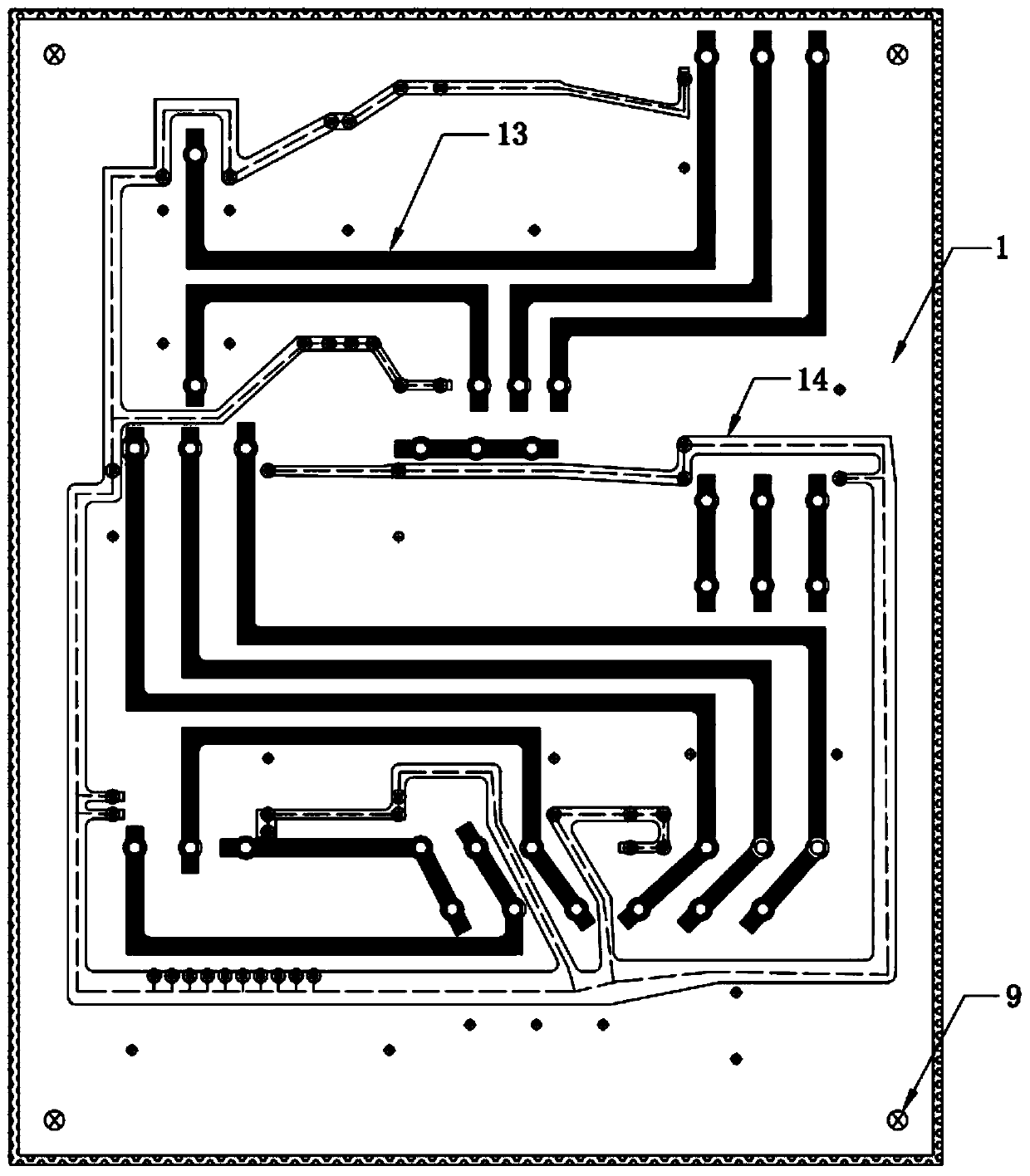

[0042] Such as figure 1As shown, a whole fully sealed prefabricated electrical circuit board includes: a substrate 1, a wire 2, a wire connector 3 and an insulating packaging material 4, and the front side of the substrate 1 is used to fix the electrical device, so that the electrical device and the electrical device are maintained. Sufficient safety insulation spacing and heat dissipation space.

[0043] The back side opposite to the front is fixed and supports the wire 2, and the wire 2 is used to connect electrical devices. In order to make the electric circuit board as thin as possible, the wire 2 is as flat as possible.

[0044] The wire connector 3 is fixed on the base plate 1 and is used to connect the wire 2 and the external wiring harness. The lower part of the wire connector 3 is connected to the wire 2 on the back of the base board 1, and is usually connected by hot-melt welding or riveting; the wire The upper part of the connecting piece 3 is connected to the exte...

Embodiment 2

[0067] The difference between this embodiment and the overall fully sealed prefabricated electrical circuit board of Embodiment 1 is that the material of the substrate 1 is an insulating board, and the back of the substrate 1 is provided with a groove 8, and the groove 8 is used for fixing the embedded wire 2, insulating The encapsulation material 4 is used to fill the trench 8 .

[0068] Making an integral fully sealed prefabricated electrical circuit board of this embodiment includes the following steps:

[0069] (1) Pre-embed the wire connector 3 and the nut 10 for fixing the electrical device on the substrate 1, and connect the wire connector 3 by hot melting or riveting;

[0070] (2) The substrate 1 is an insulating board, and the wire 2 is fixed inside the substrate 1. On the back of the substrate 1, according to the connection requirements of the wire 2 in the electrical schematic diagram of the electric control equipment, a groove 8 with a suitable depth and width is o...

Embodiment 3

[0073] The difference between this embodiment and the overall fully sealed prefabricated electrical circuit board of Embodiment 1 is that the material of the substrate 1 is an insulating board, the wires 2 are attached to the back of the substrate 1, and the insulating packaging material 4 is poured on the back of the substrate 1 to cover the wires. 2. The insulating encapsulation material 4 casts the substrate 1 and the wires 2 through a casting mold. That is, the substrate 1 with the wire 2 and the wire connector 3 fixed is put into the casting mold, and the insulating packaging material 4 is injected into the casting mold for one-time molding, so that the electrical circuit board is complete and seamless. The insulating encapsulation material 4 can adopt gel-like insulating material, such as ABS engineering plastics. The substrate 1 described in this embodiment does not directly bear the weight of the electrical device, but only bears the weight of the wire 2 and other emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com