Furrower and seeder using same

A ditch opener and seeder technology, which is applied in the direction of sowing seeders, digging/covering ditches, applications, etc., can solve the problems of inconvenient use, laborious ditching process, heavy ditching equipment, etc., and achieve low cost and easy ditching Good effect, reduce the effect of traveling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

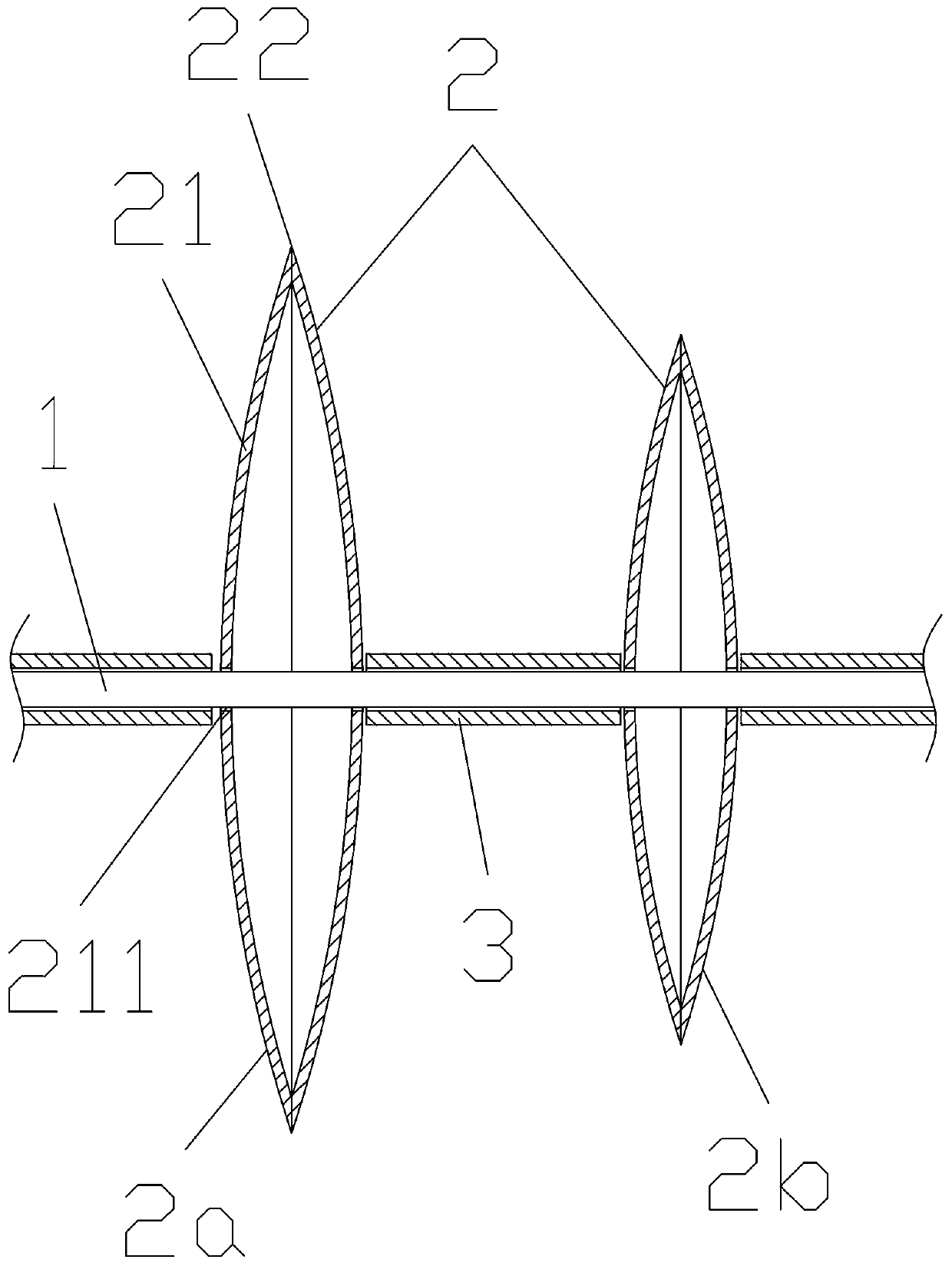

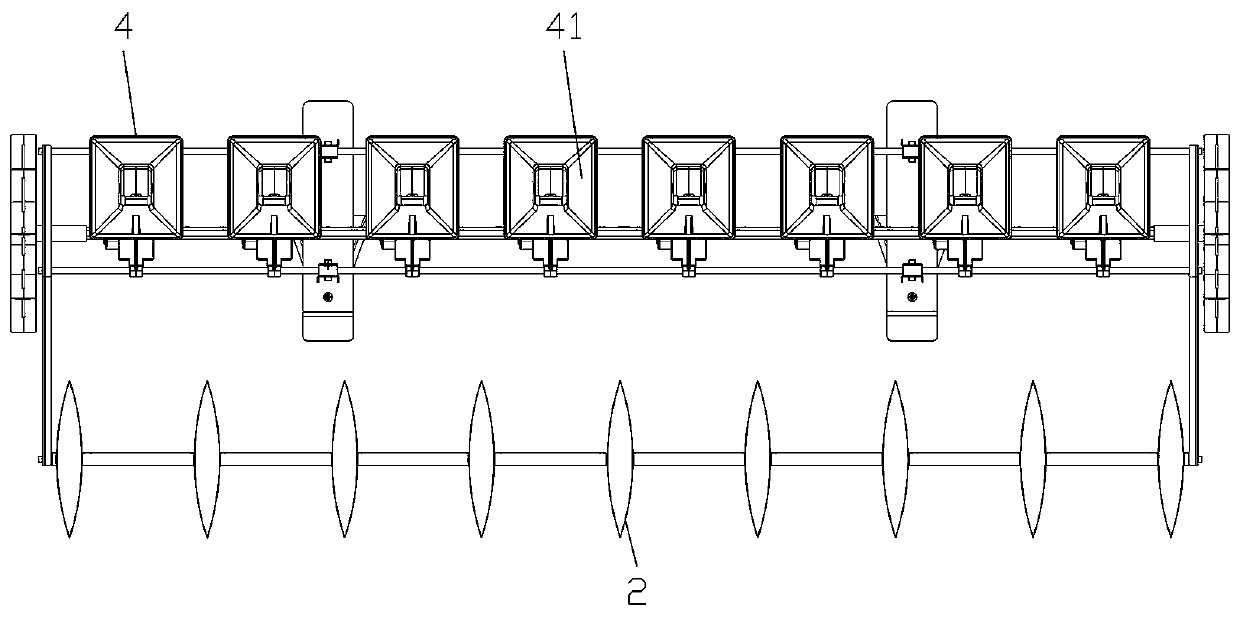

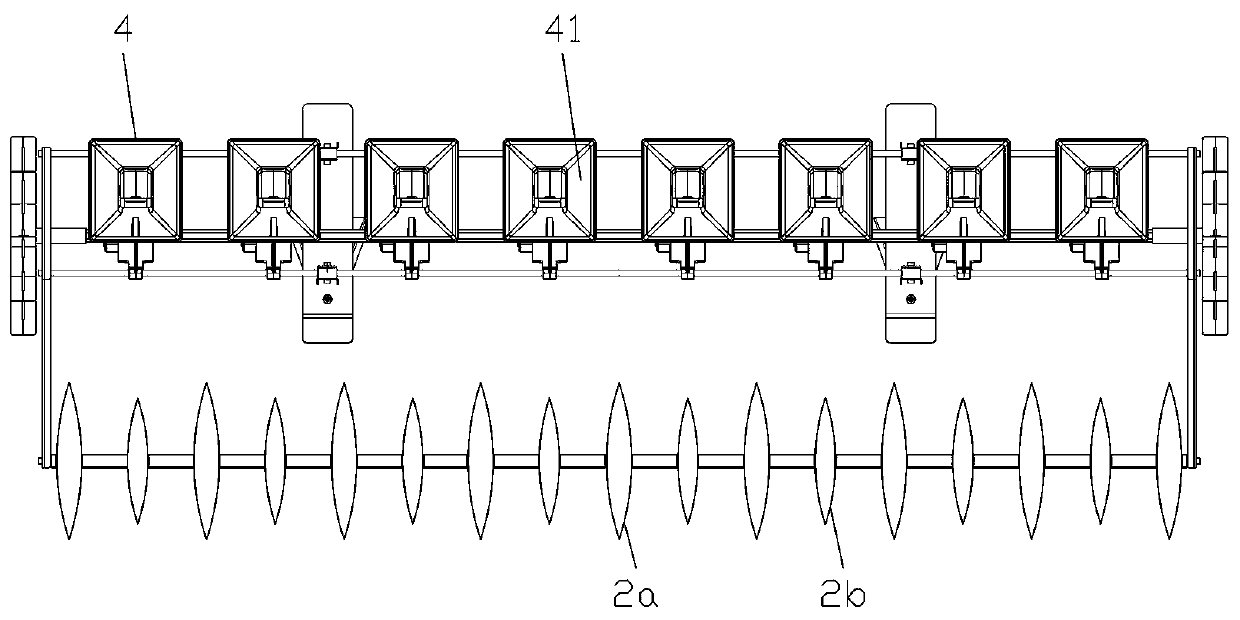

[0030] Such as figure 1 , a ditch opener, including a main shaft 1 and a ditching wheel 2 mounted on the main shaft 1; the ditching wheel 2 is disc-shaped, and each ditching wheel 2 includes two side discs 21, and the two side discs 21 are outside The circles intersect to form an annular rib 22 ; the center of the side plate 21 is provided with a mounting hole 211 , and the mounting hole 211 is passed through by the main shaft 1 for installation.

[0031] Thus, the ditching wheel 2 can rotate, and the annular edge 22 is embedded in the muddy ground, and the ditching can be carried out by rolling when ditching in the field. Compared with the traditional ditching device, the resistance is smaller, and the surface of the side plate 21 is smooth and smooth. It is easy to bond the soil, further reducing the running resistance.

[0032] Such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com