Automatic strawberry cleaning and packaging system and method

An automatic cleaning and packaging system technology, applied in packaging, packaged food, packaging protection, etc., can solve problems such as difficult operation effect, large manpower occupation, broken and corrupt strawberries, etc., to ensure uniform taste, improve delivery efficiency, and facilitate packing The effect of homework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

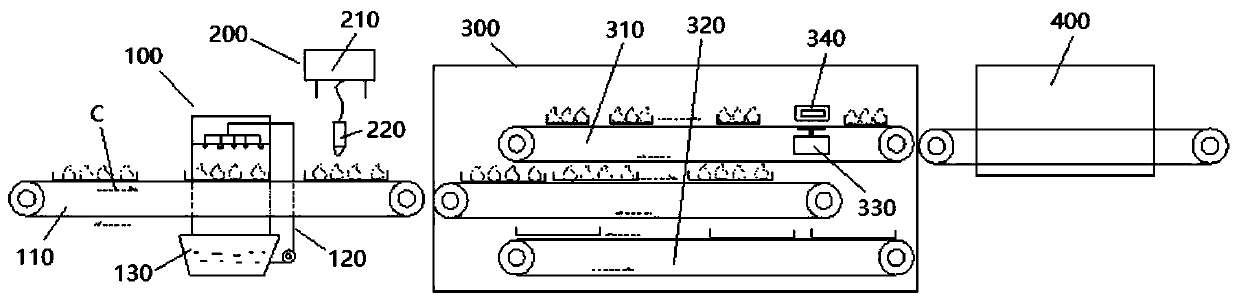

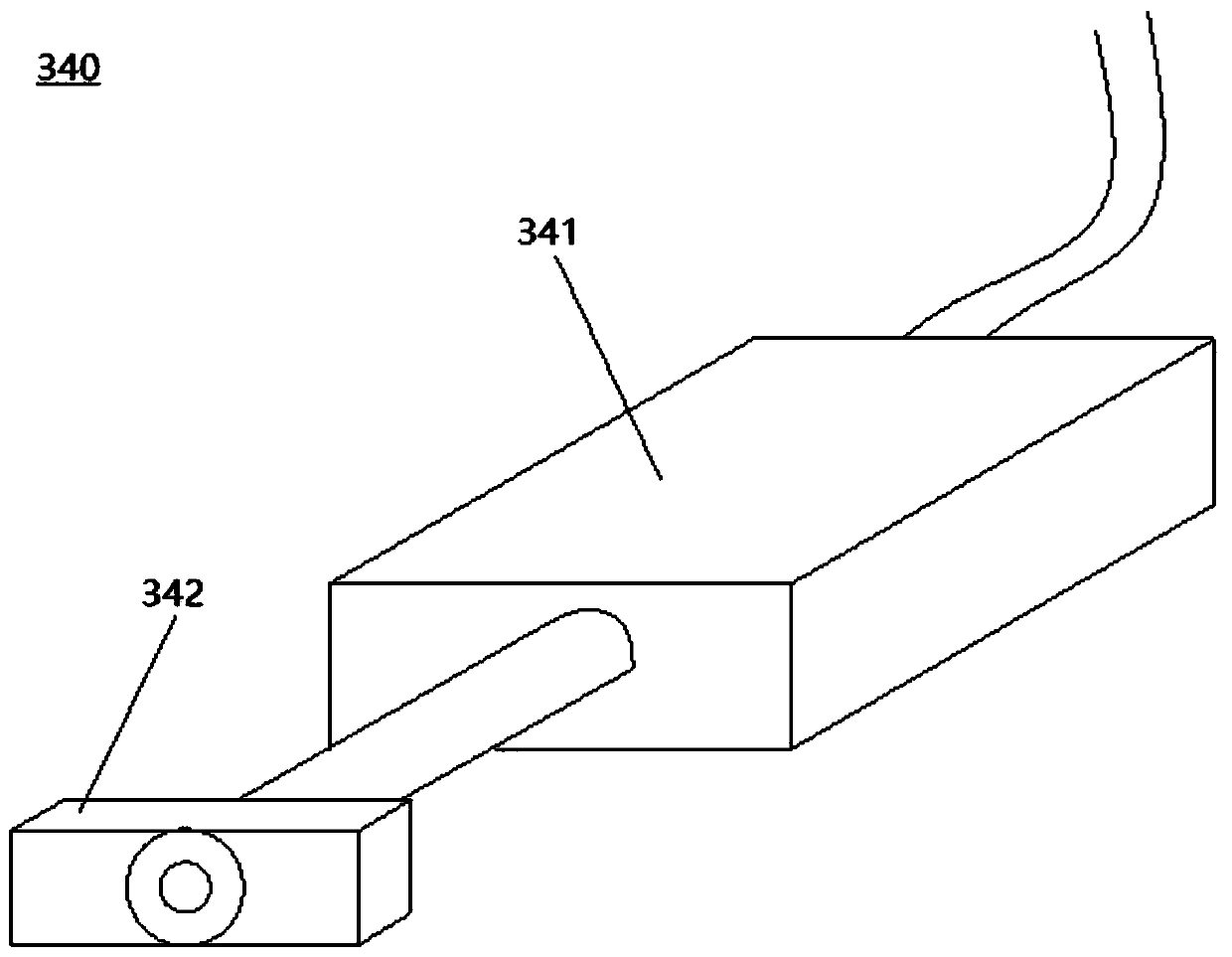

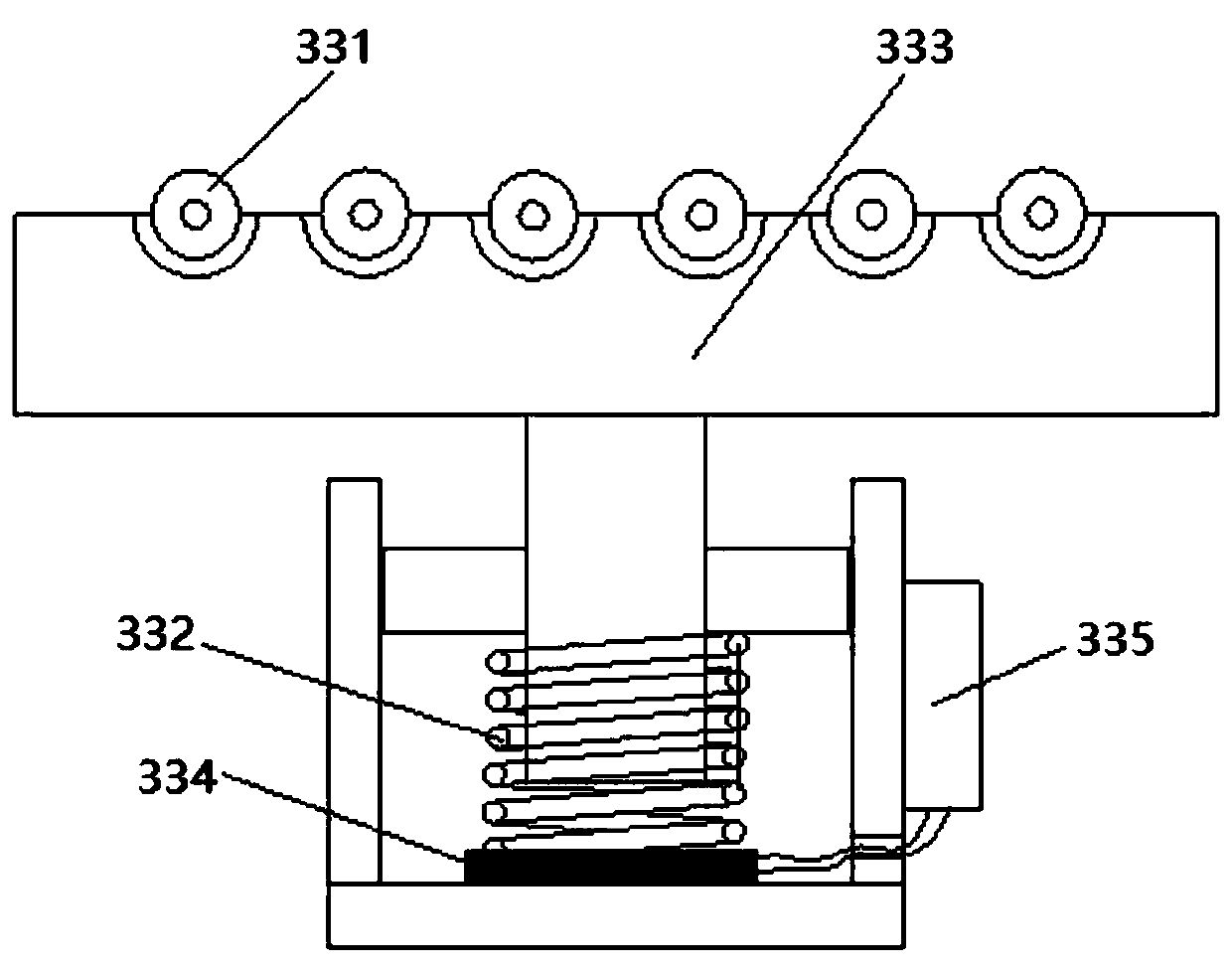

[0039] Such as figure 1As shown, the present invention provides a strawberry automatic cleaning and packaging system, including: a strawberry automatic packaging machine 400; also includes: a strawberry cleaning machine 100 that is arranged on the same single-line conveying line in sequence according to the logistics direction, and conveys materials in a belt conveying manner , Strawberry Air Dryer 200 and Strawberry Sorting Machine 300; the output end of the Strawberry Sorting Machine 300 and the Strawberry Automatic Packing Machine 400 realize the delivery of strawberry materials through a conveyor belt;

[0040] The structure of the strawberry cleaning machine 100 includes: a belt conveyor 110, a spray device 120 and a water tank 130 whose conveyor belt profile is grid-like; the spray device 120 is arranged directly above the belt conveyor 110 and spray The coverage area of the shower area is adapted to the conveyor belt width and conveying length of the belt conveyor 110...

Embodiment 2

[0052] The present embodiment further provides a method for automatically cleaning and packaging strawberries on the basis of Embodiment 1, said method comprising the steps of:

[0053] Step 1: Use a strawberry cleaning machine to wash away the dust attached to the outer surface of the strawberries;

[0054] Step 2: Dry the moisture attached to the cleaned strawberries through a strawberry air dryer;

[0055] Step 3: The strawberry sorting machine automatically removes finished product trays full of strawberries whose weight is lower than the set value;

[0056] Step 4: Complete the automatic film-laminated packaging of the finished product tray full of strawberries and weighing more than the set value through the strawberry automatic packaging machine;

[0057] Step 5: Automatically output the film-coated finished product tray to the output end of the automatic strawberry packaging machine.

[0058] Furthermore, in one of the preferred technical solutions of this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com