Preparation method of surface coating of orthopedic implantation instrument

A surface coating and device technology, which is applied in the field of surface modification of orthopedic implant devices, can solve the problems of limited pH-responsive controlled release performance, difficult antibacterial and osteogenic functions, and large gaps in required concentrations to achieve good osteogenesis effects , The preparation method is simple and convenient, and the effect of good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

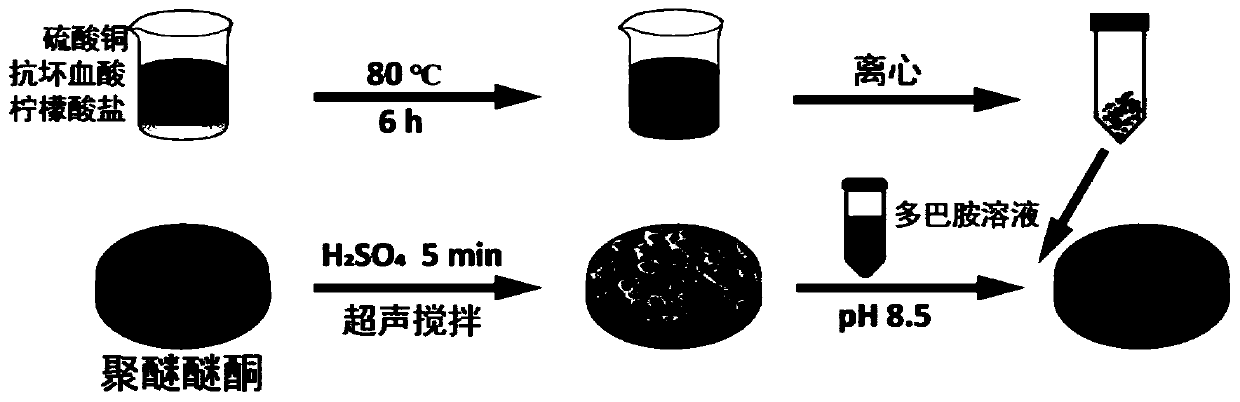

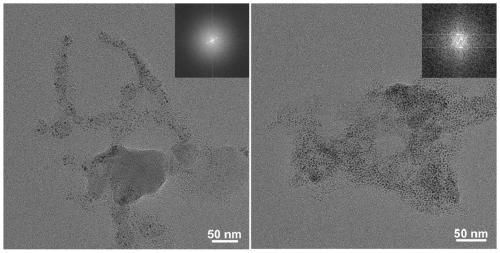

[0031] The process of preparing polydopamine coating containing copper-citrate composite nanoclusters on the surface of polyether ether ketone is as follows: figure 1 As shown, the specific steps are as follows:

[0032] (1) Substrate material pretreatment: select medical grade PEEK rods, and use mechanical processing technology to cut them into Φ15x1.5mm 3 The discs were polished step by step with 400#, 800#, 1200#, 1500# and 2000# metallographic sandpaper, and then ultrasonically cleaned in acetone, ethanol and deionized water for 20 minutes, and the surface moisture was dried with filter paper. Air-dried and stored in a vacuum oven;

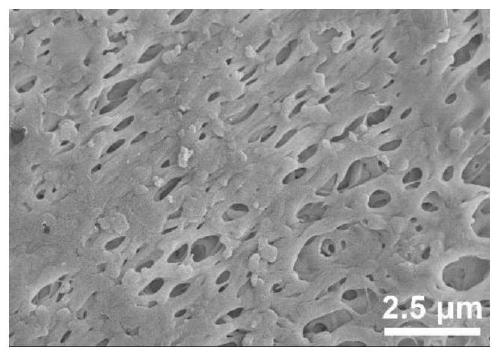

[0033] (2) Polyether ether ketone sulfonation treatment: PEEK sample was added into concentrated sulfuric acid, and stirred ultrasonically for 5 minutes. The samples were then taken out and ultrasonically cleaned in deionized water for 20 minutes. After cleaning, put the sample into a beaker with deionized water, heat it on a resistance fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com