Hydroxyl formaldehyde removal system

A formaldehyde and hydroxyl technology, applied in the field of hydroxyl formaldehyde removal system, can solve the problems of general effect, slow effect, harmfulness, etc., and achieve the effect of improving purification effect and mixing uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

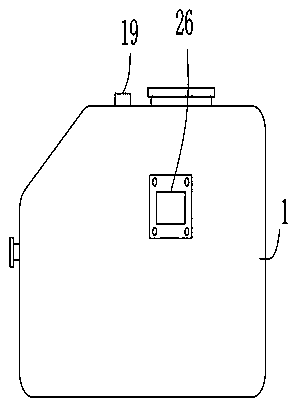

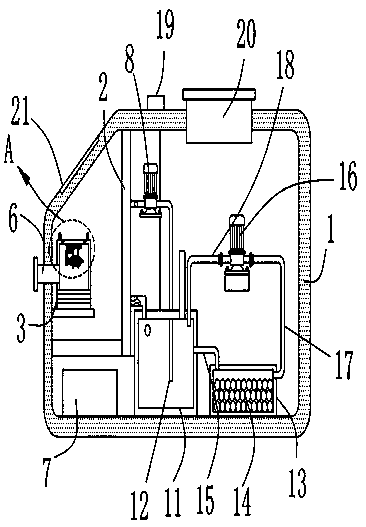

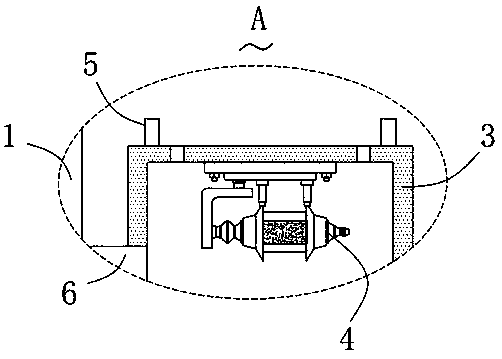

[0023] Please refer to Figure 1-4 , in the first embodiment of the present invention, the hydroxyl formaldehyde removal system includes: a housing 1; three water curtains 2, and the three water curtains 2 are all fixedly installed on the inner wall of the housing 1; the air intake channel 6. The air intake channel 6 is fixedly installed on one side of the housing 1; the installation frame 3, the installation frame 3 is fixedly installed on the air intake channel 6, and the installation frame 3 and the housing The inner wall of the body 1 is fixedly connected; the UV ultraviolet germicidal lamp 4, the UV ultraviolet germicidal lamp 4 is fixedly installed on the mounting frame 3; the plasma generator 5, the plasma generator 5 is arranged on the mounting frame 3; Water pump 8, said water pump 8 is fixedly mounted on one side of said water curtain 2; three water tanks 9, said three water tanks 9 are respectively arranged in three said water curtains 2; water tank 11, said water t...

no. 2 example

[0038] Based on the hydroxyl formaldehyde removal system provided in the first embodiment of the present application, the second embodiment of the present application proposes another hydroxyl formaldehyde removal system. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0039] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0040] Please refer to Figure 5The hydroxyl formaldehyde removal system also includes an arched bracket 22, which is fixedly installed on the top of the water tank 11, and a motor 23 is fixedly installed on the arched bracket 22, and the output shaft of the motor 23 is fixed A stirring rod 24 is installed, and folded blades 25 are fixedly installed on the stirring rod 24 .

[0041] The top of the water tank 11 is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com