Motor vehicle license plate erasing machine

A character erasing machine and motor vehicle technology, which is applied in the field of motor vehicle number plate production equipment, can solve the problems of low wiping efficiency and poor wiping effect, and achieve the effect of realizing automatic operation, improving the effect of wiping characters, and avoiding disengagement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

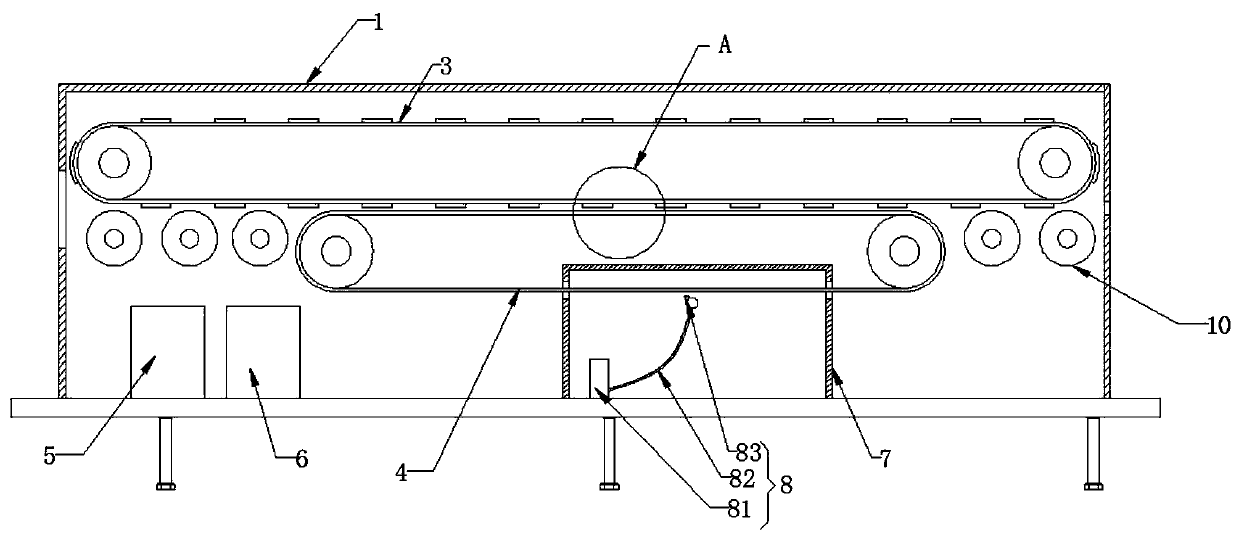

[0036] This embodiment, as the basic embodiment of the present invention, discloses a motor vehicle number plate erasing machine, the specific structure is as follows figure 1 As shown, a frame 1 is included, and a controller 2 is fixedly arranged on the frame 1. The controller 2 includes a PLC 24 and a touch screen 25 that realize communication connection through the RS485 bus. There are a feeding belt 3 and a word wiping belt 4, and the feeding belt 3 and the word wiping belt 4 are arranged oppositely, and between the feeding belt 3 and the word wiping belt 4 is a passage for the number plate to pass through; the feeding belt 3 and the word wiping belt 4 The two ends of the rollers are respectively connected with the corresponding rollers, and the rollers are respectively connected with the feeding motor 5 and the word erasing motor 6 through the transmission device of the gear or the pulley; The two motors run in opposite directions;

[0037] The uniform fixing of describe...

Embodiment approach 2

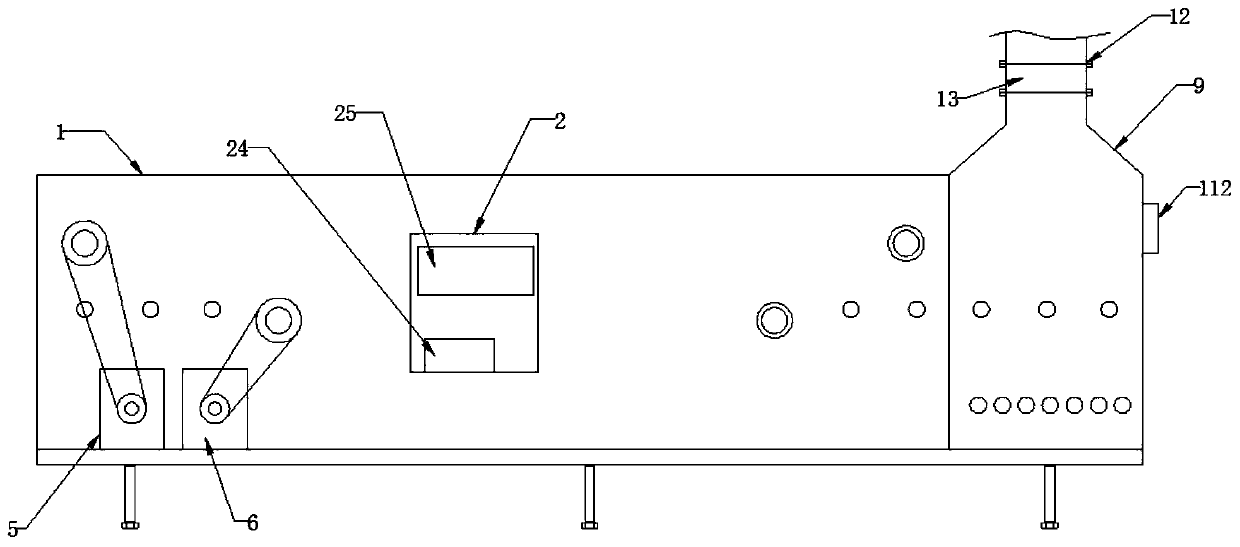

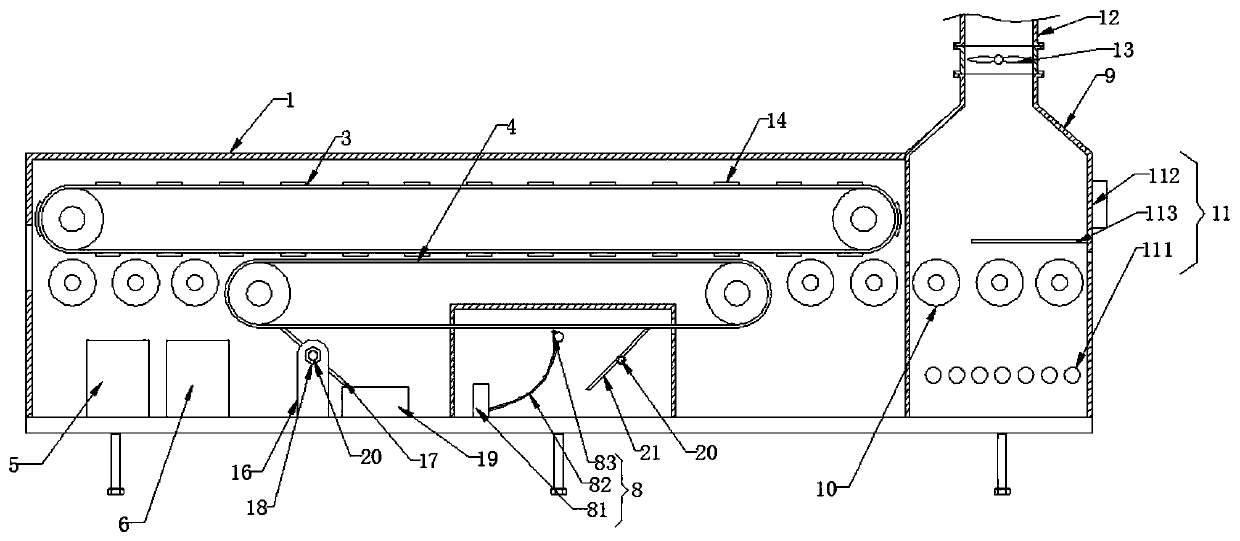

[0040] This embodiment, as a preferred embodiment of the present invention, discloses a motor vehicle number plate erasing machine, the specific structure is as follows figure 2 As shown, it includes a frame 1, the frame 1 is provided with a controller 2, and the controller 2 includes a PLC24 and a touch screen 25 that realize communication connection through the RS485 bus. A feeding belt 3 and a word erasing belt 4 are provided, and along the movement direction of the word erasing belt 4, an adjusting bracket 16, a waste recycling box 19 and a solvent box 7 are sequentially arranged on the lower part of the frame 1, and the adjusting bracket 16 is connected through a rotating shaft There is a scraper 17, one end of the scraper 17 is inclined upwards, and is in contact with the surface of the wiping belt 4, thereby scraping off the residue on the wiping cloth 26; the other end is inserted into the waste recycling box 19;

[0041] The solvent box 7 is provided with a rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com