CAN bus controller parallel test method

A CAN bus and test method technology, applied in the field of parallel testing of CAN bus controllers, can solve the problems of inoperable state consideration, tedious debugging and writing test PATTERN, no CAN bus transceiver, etc., to avoid debugging and writing PATTREN process, Achieve full functional coverage testing and improve testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

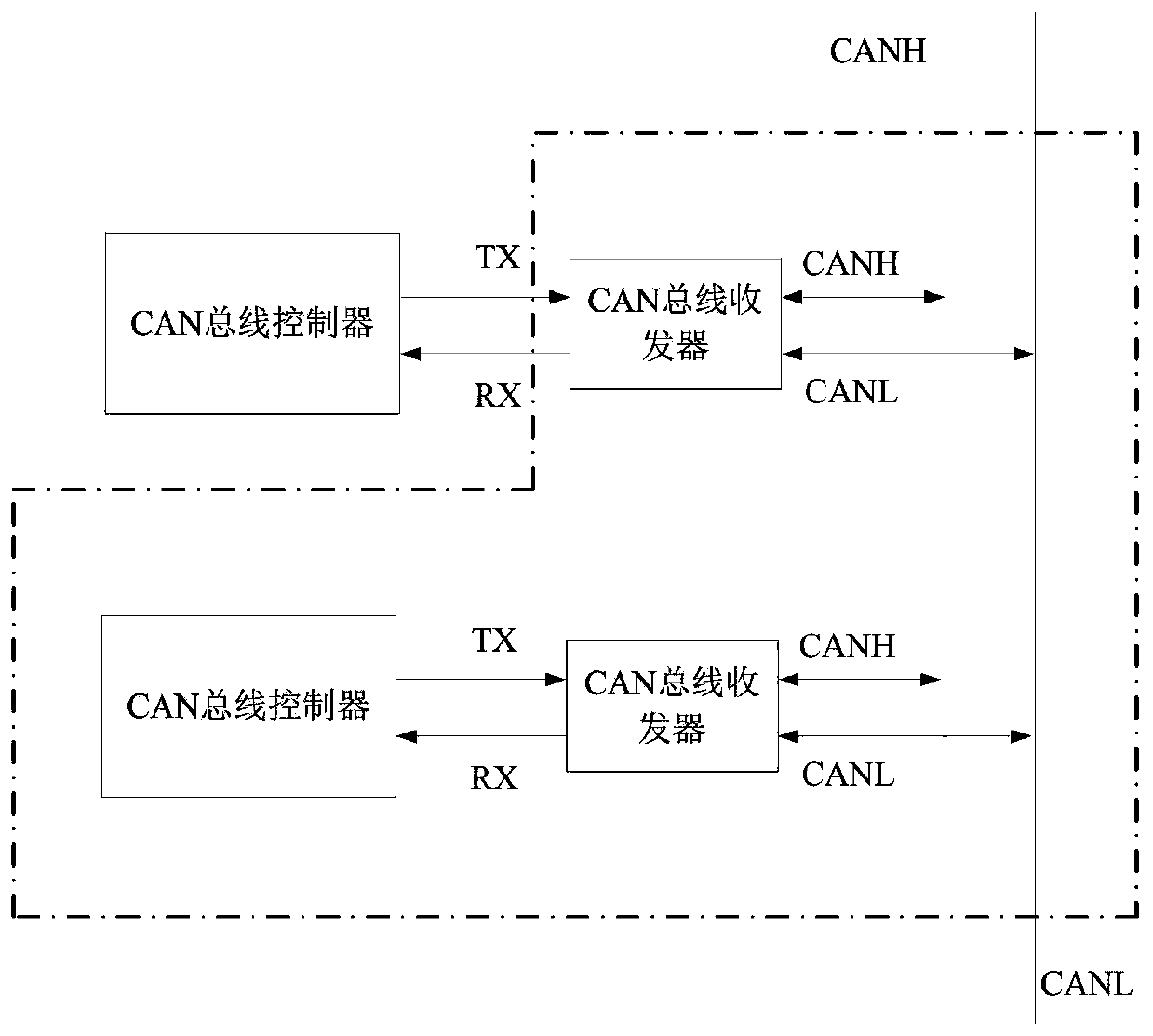

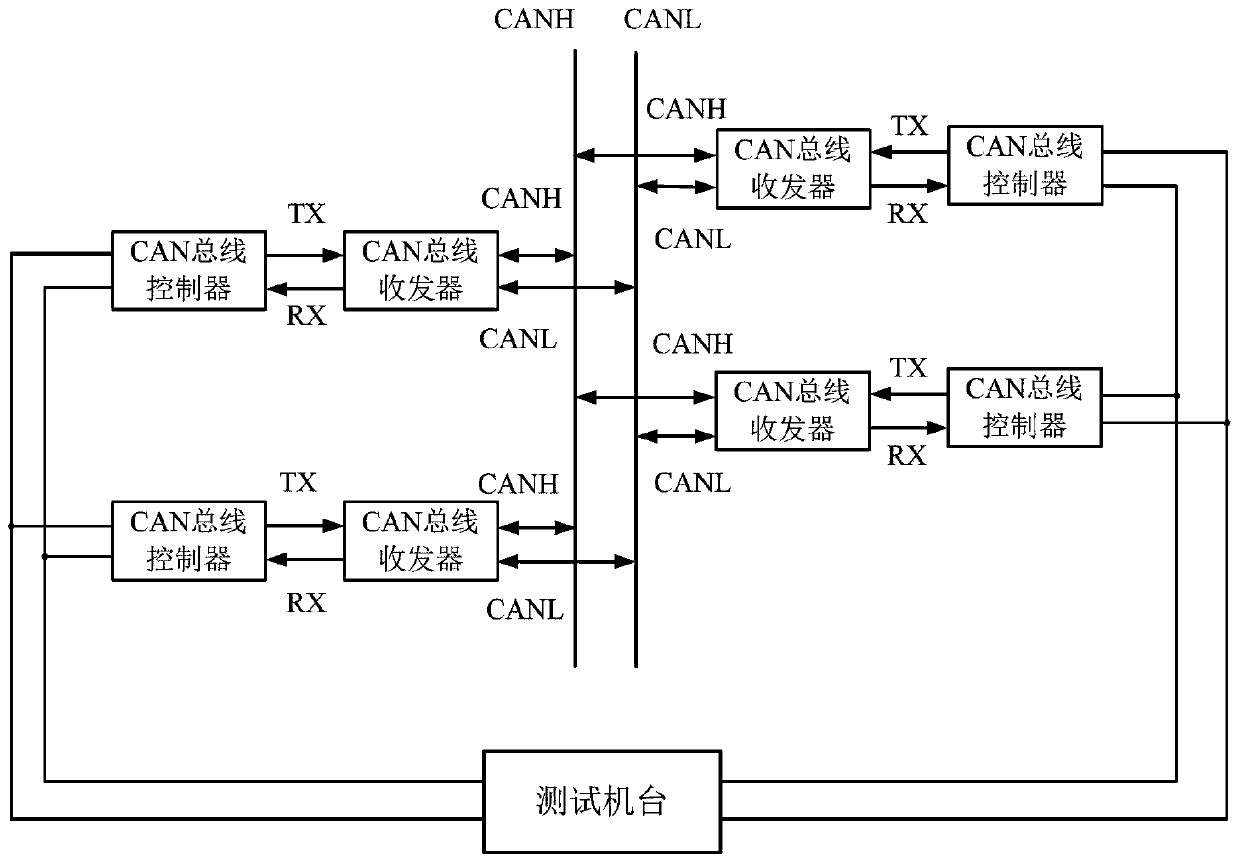

[0060] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

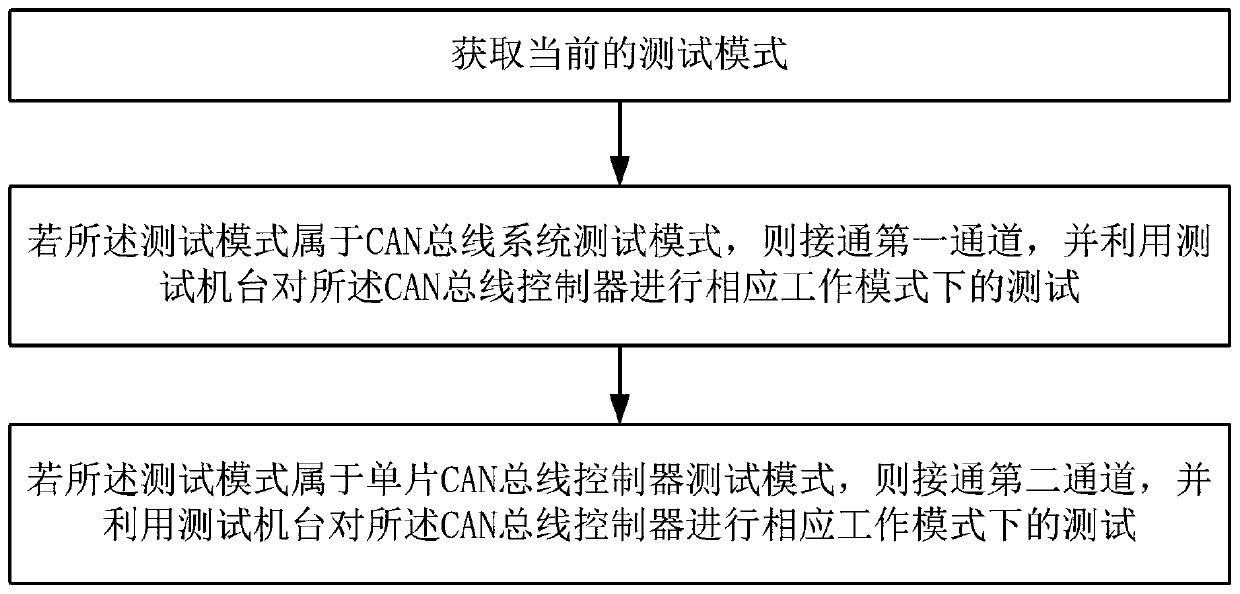

[0061] A specific embodiment of the present invention discloses a parallel testing method of a CAN bus controller, the flow chart is as figure 2 As shown, the method includes the following steps:

[0062] Step S1: Obtain the current test mode;

[0063] Step S2: If the test mode belongs to the CAN bus system test mode, then connect the first channel, and use the test machine to test the CAN bus controller in a corresponding working mode;

[0064] Step S3: If the test mode belongs to the single-chip CAN bus controller test mode, then connect the second channel, and use the test machine to tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com