Electrostatic flash micro-spray circulation cooling system for high-power chip heat dissipation

A circulating cooling system and chip heat dissipation technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of miniaturization, integrated cooling system design and packaging, difficult precise cooling of semiconductor chips, explosive fragmentation of refrigerants, etc. problem, to avoid the sharp increase of the chip temperature, improve the cooling efficiency and uniformity, and achieve the effect of high atomization quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific drawings and embodiments.

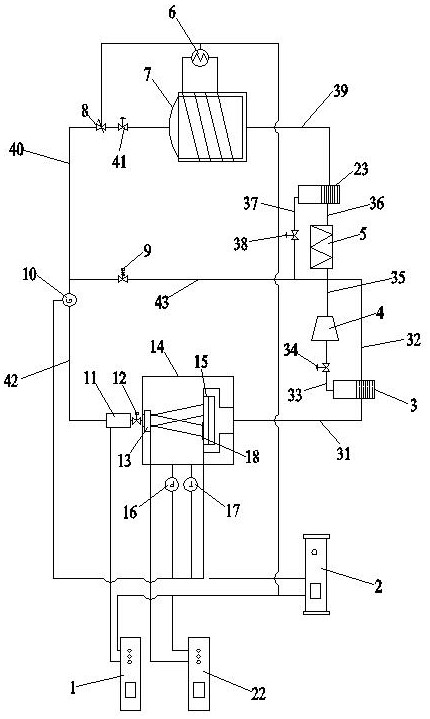

[0038] Such as figure 1 Shown: In order to effectively solve the high-efficiency heat dissipation of high-power chips and improve cooling efficiency, the present invention includes a spray chamber 14 that can accommodate high-power chips to be dissipated, a charging chamber 11 that can make the cooling medium carry charges, and can communicate with the above-mentioned The spray chamber 14 and the charging chamber 11 are adapted to connect the cooling medium refrigeration cycle pipeline mechanism;

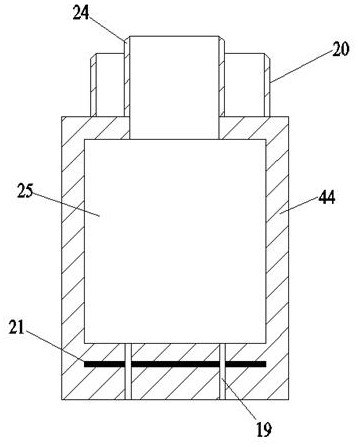

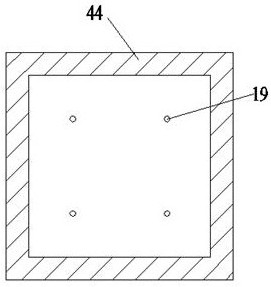

[0039] The charging chamber 11 is located above the spray chamber 14 and the charging chamber 11 communicates with the micro-channel nozzle 13 in the spray chamber 14, and the spray chamber 14 is provided with a heat sink that can contact and cooperate with the high-power chip to be dissipated 15, the heat sink 15 is located directly below the microchannel nozzle 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com