Heater control method, heater and deicing vehicle

A control method and heater technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., can solve problems such as temperature instability, and achieve the effect of temperature stability, reduction of adjustment time, and reduction of changing parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

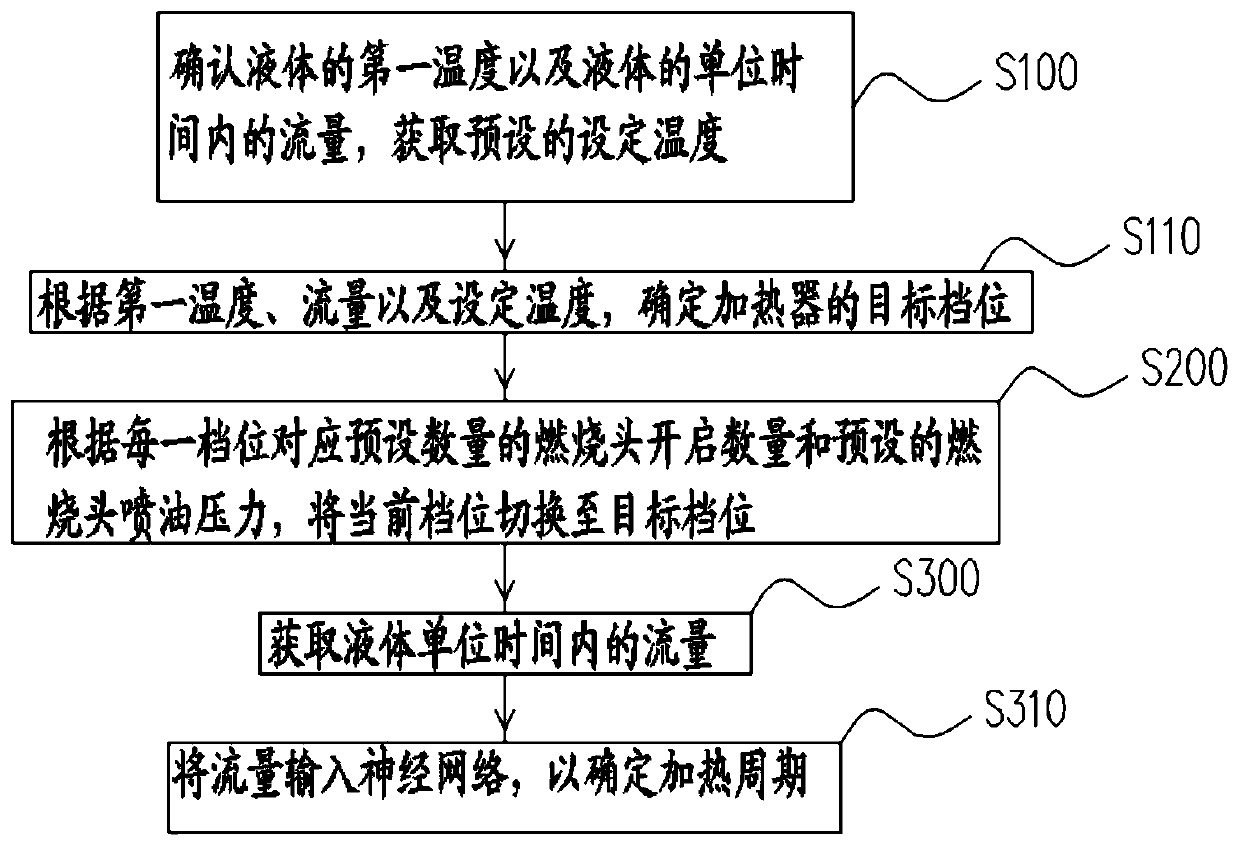

Method used

Image

Examples

Embodiment approach

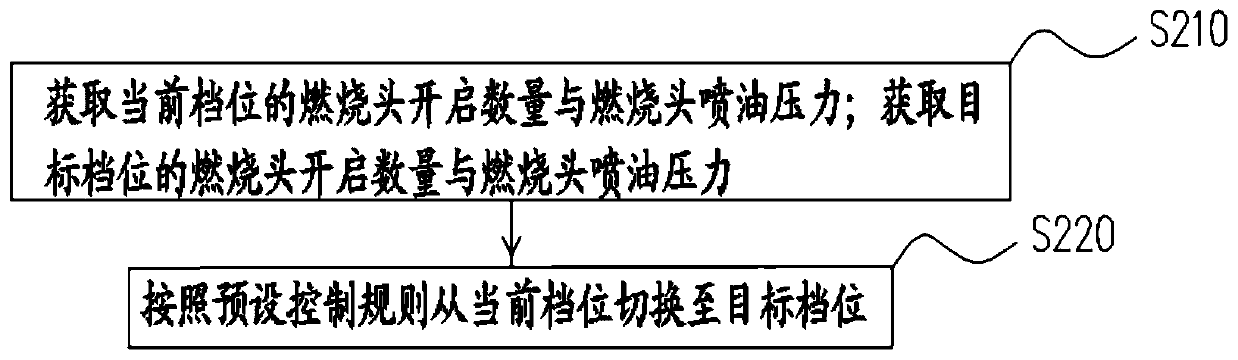

[0152] A possible implementation manner, step S223 specifically includes:

[0153] S223a. Select a gear between the transition gear and the current gear as the first intermediate gear. Among them, for one of the number of openings of the combustion head and the fuel injection pressure of the combustion head, the first intermediate gear and the transition gear are the same as the current gear; for the other of the number of openings of the combustion head and the fuel injection pressure of the combustion head, the transition The gear, the first intermediate gear and the current gear are in a decreasing or increasing relationship.

[0154] S223b. Adjust the other one of the number of openings of the combustion head and the fuel injection pressure of the combustion head, so as to switch from the current gear to the first intermediate gear.

[0155] S223b. Adjust the other one of the number of openings of the combustion head and the fuel injection pressure of the combustion head,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com