Ultrahigh-pressure cold-sterilized cow milk and production method thereof

A production method and ultra-high pressure technology, applied in the field of milk production, can solve the problem of not being able to completely kill pathogenic bacteria, and achieve the effect of retaining fresh flavor and nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

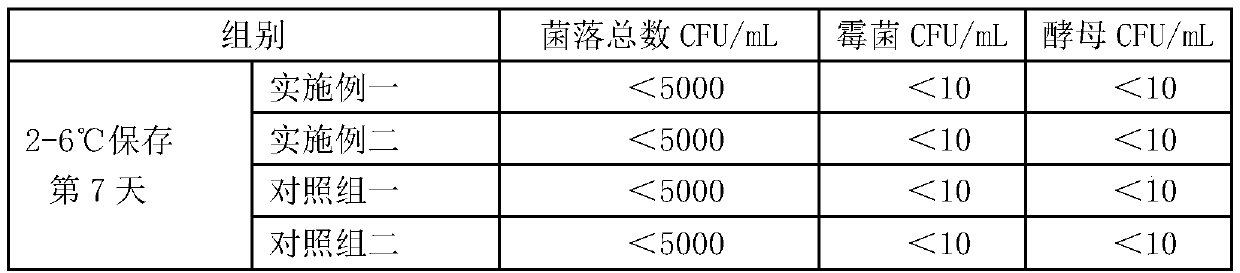

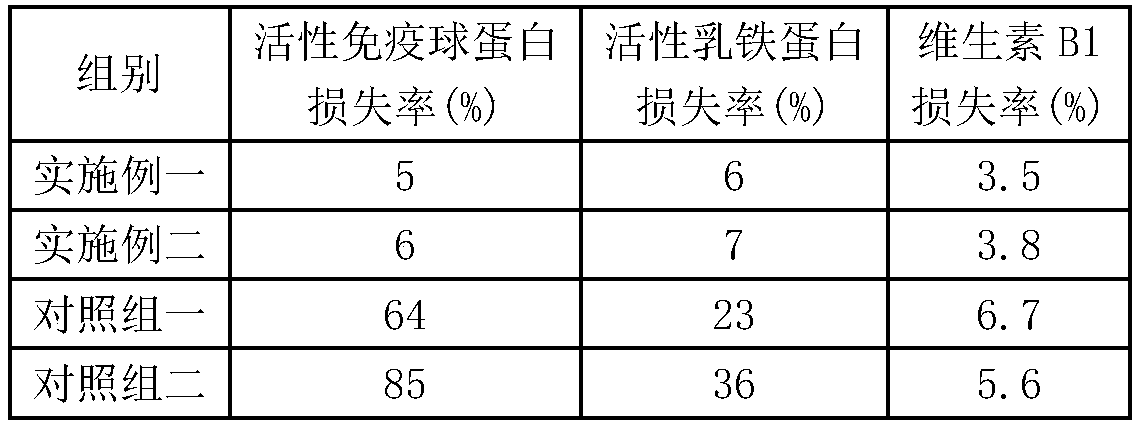

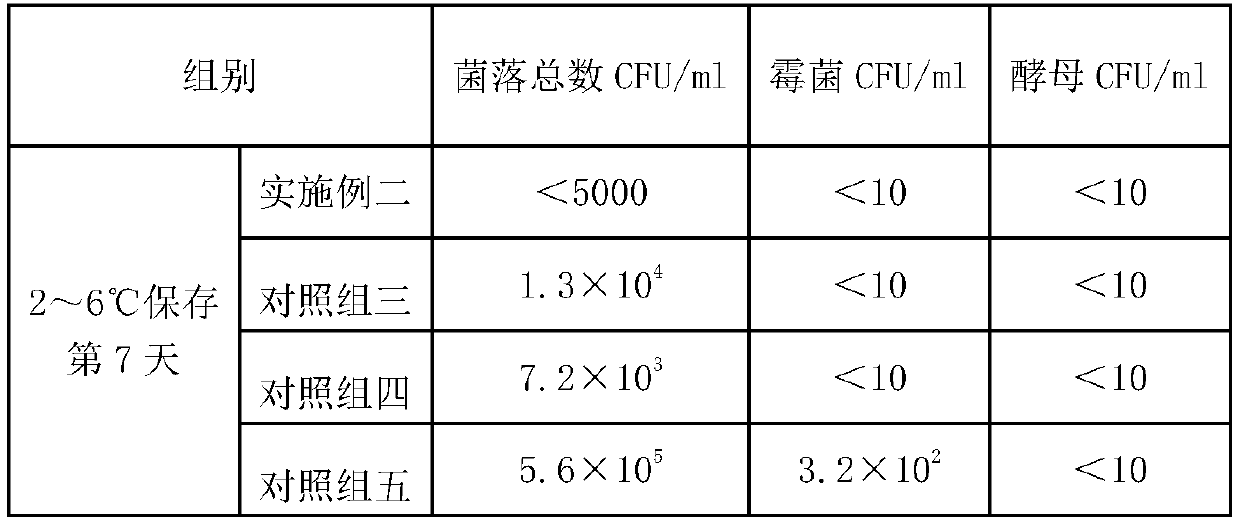

Examples

Embodiment 1

[0026] Select raw milk that meets the requirements of milk source quality as the source of raw materials. The indicators of raw milk are that the total number of colonies is 5,000 CFU / mL, the number of somatic cells is 200,000 / mL, and coliforms, Staphylococcus aureus, and Salmonella are not allowed to be detected in every 25 mL. out. Furthermore, fixed pastures with mature and advanced management levels, excellent and relatively stable quality of milk produced in the past year can be selected as the source of raw milk. The raw milk was immediately cooled to 2°C for refrigerated storage, and within 4 hours of collection, it was filled into elastic plastic bottles with aseptic filling equipment in a clean environment. After filling, the residual air in the bottle was 1%. The filled raw milk is stored at 2-6°C.

[0027] Within 12 hours after filling, the filled raw milk was sterilized under 500MPa for 20 minutes by ultra-high pressure treatment. The medium for the ultra-high p...

Embodiment 2

[0030] Select raw milk that meets the requirements of milk source quality as the source of raw materials. The indicators of raw milk are that the total number of colonies is 2,000 CFU / mL, the number of somatic cells is 150,000 / mL, and coliforms, Staphylococcus aureus, and Salmonella are not allowed to be detected in every 25 mL. out. Furthermore, fixed pastures with mature and advanced management levels, excellent and relatively stable quality of milk produced in the past year can be selected as the source of raw milk. The raw milk was immediately cooled to 6°C for refrigerated storage, and within 6 hours of collection, it was filled into elastic plastic bottles with aseptic filling equipment in a clean environment. After filling, the residual air in the bottle was 0.5%. The filled raw milk is stored at 2-6°C.

[0031] Within 6 hours after filling, the filled raw milk was sterilized under 600MPa for 5 minutes by ultra-high pressure treatment. The medium for the ultra-high p...

Embodiment 3

[0034] Select raw milk that meets the requirements of milk source quality as the source of raw materials. The indicators of raw milk are that the total number of colonies is 1000CFU / mL, the number of somatic cells is 150000 / mL, and coliforms, Staphylococcus aureus, and Salmonella are not allowed to be detected in every 25mL. out. Furthermore, fixed pastures with mature and advanced management levels, excellent and relatively stable quality of milk produced in the past year can be selected as the source of raw milk. The raw milk was immediately cooled to 4°C for refrigerated storage, and within 3 hours of collection, it was filled into elastic plastic bags with aseptic filling equipment in a clean environment. After filling, the residual air in the bags was 0. The filled raw milk is stored at 2-6°C.

[0035] Within 8 hours after filling, the filled raw milk was sterilized at 550MPa for 10 minutes by ultra-high pressure treatment. The medium for the ultra-high pressure treatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com