Nutrition enhancer for improving production performance of laying hens after forced moulting

A nutritional fortifier and forced moulting technology, applied in the field of breeding to achieve the effects of relieving stress, improving egg quality and improving production performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

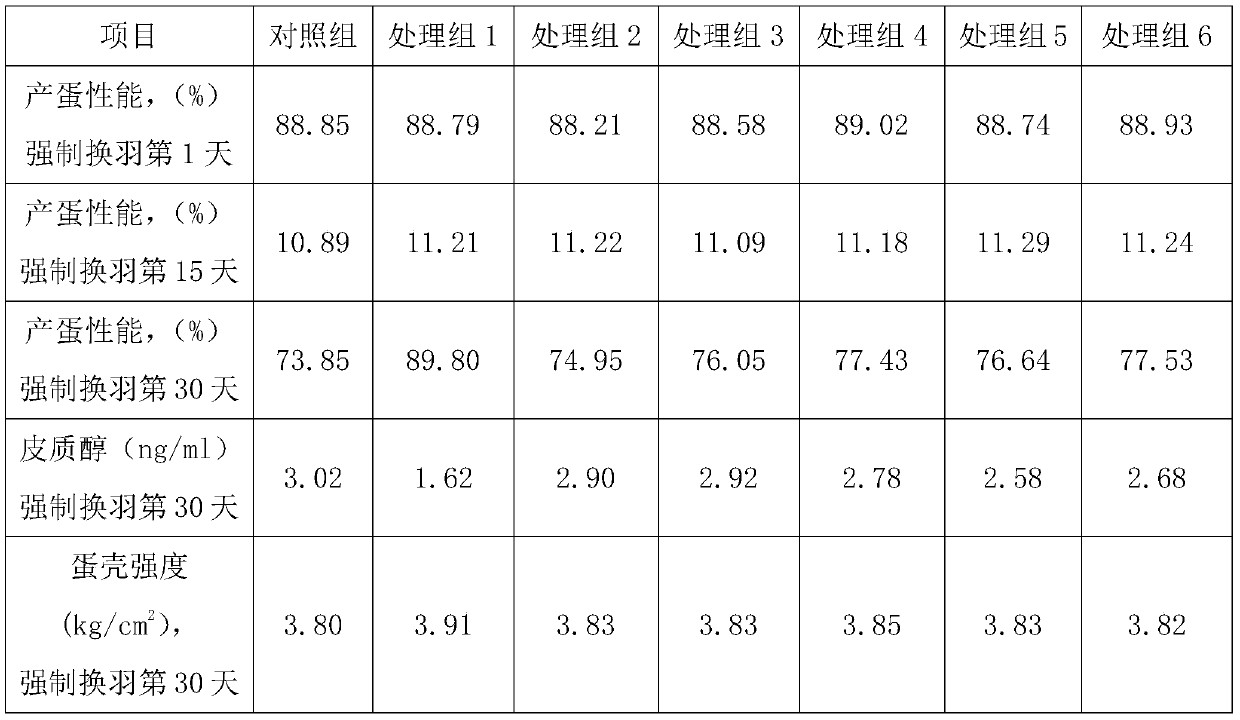

Examples

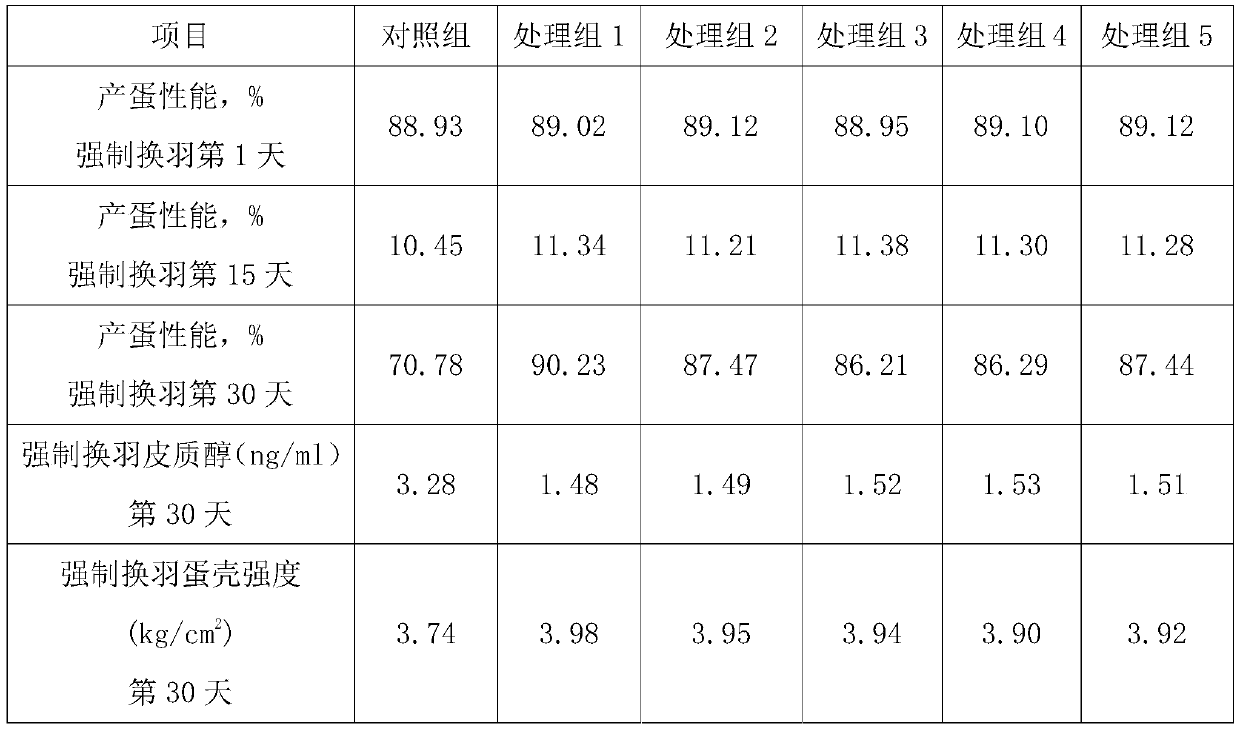

Embodiment 1

[0025] A nutritional enhancer for improving the production performance of laying hens after forced moulting, comprising the following components in parts by weight: 500 parts of Epimedium flavonoids, 100 parts of Ke Zi extract, 80 parts of itaconic acid, 100 parts of taurine and Protocatechuic acid 220 parts.

[0026] Weigh each component according to the above parts by weight, and add them into the mixer in sequence from large to small according to the proportioning ratio. After mixing evenly, use non-toxic bags for packaging to obtain this embodiment. Improve the production performance of laying hens after forced moulting nutritional enhancer.

[0027] 7 days before and 7 days after the forced molt, feed the nutritional enhancer according to any one of claims 1-2 once a day, 20g each time.

Embodiment 2

[0029] A nutritional enhancer for improving the production performance of laying hens after forced moulting, comprising the following components in parts by weight: 300 parts of Epimedium flavonoids, 100 parts of Ke Zi extract, 50 parts of itaconic acid, 150 parts of taurine and Protocatechuic acid 400 parts.

[0030] The method of preparation and use is the same as in Example 1.

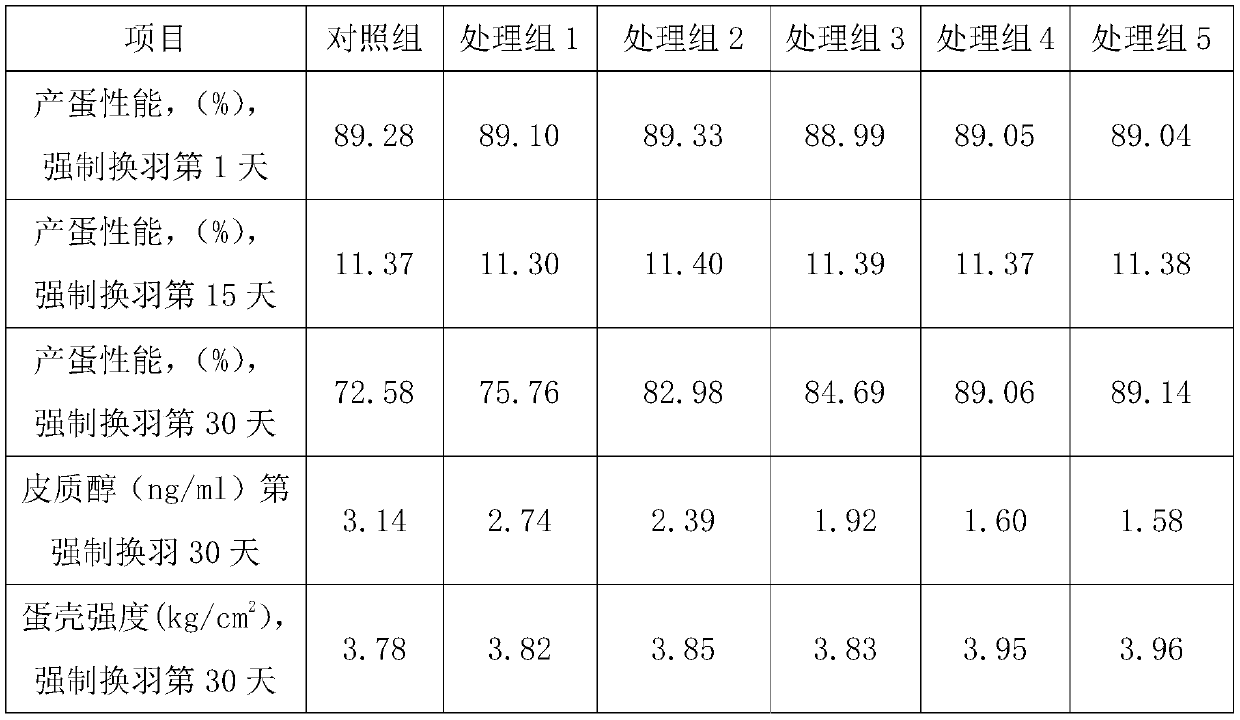

Embodiment 3

[0032] A nutritional enhancer for improving the production performance of laying hens after forced moulting, comprising the following components in parts by weight: 400 parts of Epimedium flavonoids, 150 parts of Ke Zi extract, 100 parts of itaconic acid, 100 parts of taurine and Protocatechuic acid 250 parts.

[0033] The method of preparation and use is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com