Ultraviolet LED sterilization method through optical fiber coupling and device thereof

An optical fiber coupling and sterilization device technology, applied in water supply devices, sanitary equipment for toilets, buildings, etc., can solve the problems of decreased sterilization and disinfection efficiency, failure to achieve sterilization and disinfection, power reduction, etc., to expand the application of ultraviolet sterilization and disinfection, Efficient sterilization and disinfection with little loss of luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

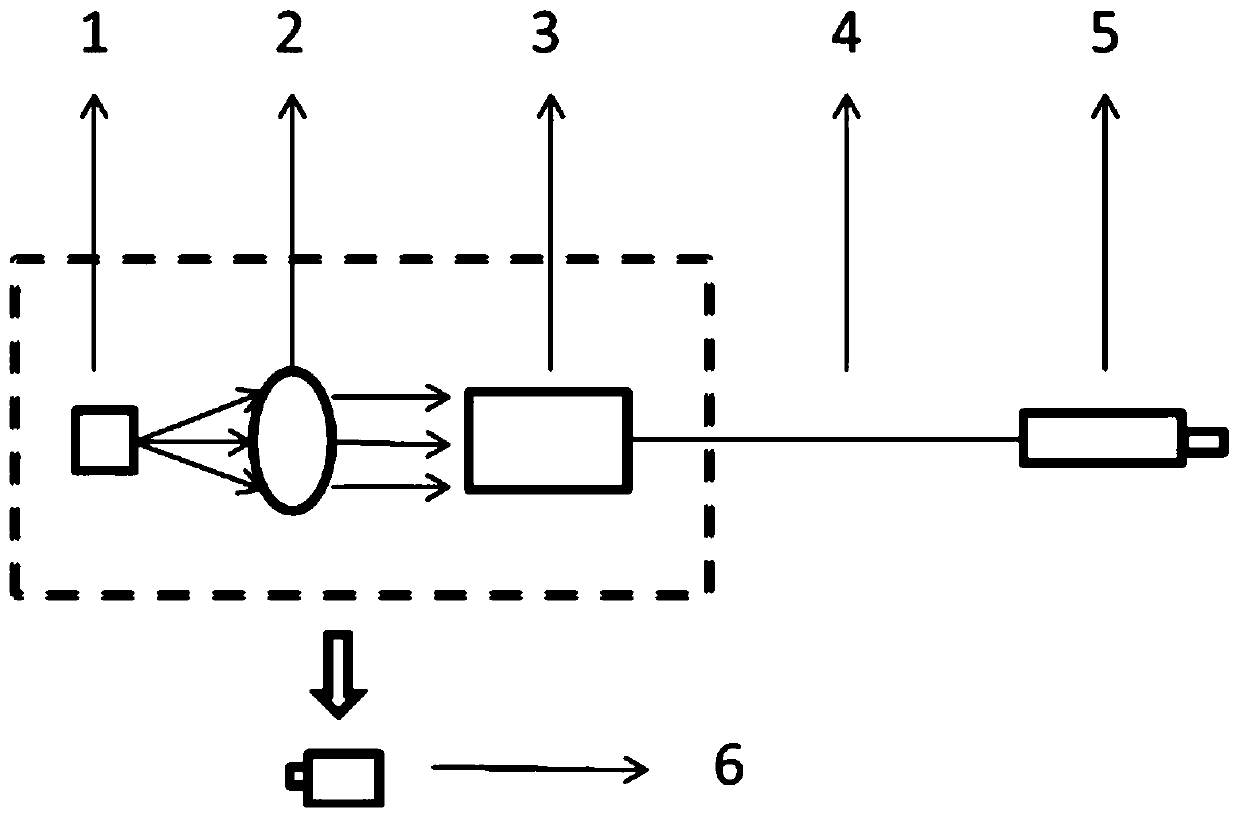

[0054] Household handheld optical fiber coupled ultraviolet LED sterilizer and sterilizing method

[0055] 1. Take 50 UV LED chips with a size of 1mm×1mm, the wavelength is 275nm, the voltage of a single chip is 6V, and the power at 350mA is 50mW. After each chip is packaged, a lens is installed, and a light collimator is installed at the same time.

[0056] 2. After the collimator, connect the optical fiber, a total of 50 optical fibers, the ultraviolet LED light coupled by these 50 optical fibers is a collimated parallel point light source, and the diameter of the point light source is about 0.5cm.

[0057] 3. Parallel the ultraviolet LED light coupled from these 50 optical fibers into a straight line to form an ultraviolet light source. The length of the line light source is 25cm.

[0058] 4. The ultraviolet light source made in the above 1-3 steps is integrated in a hand-held box, and a rechargeable power supply is also integrated in the hand-held box. The handheld box c...

specific Embodiment 2

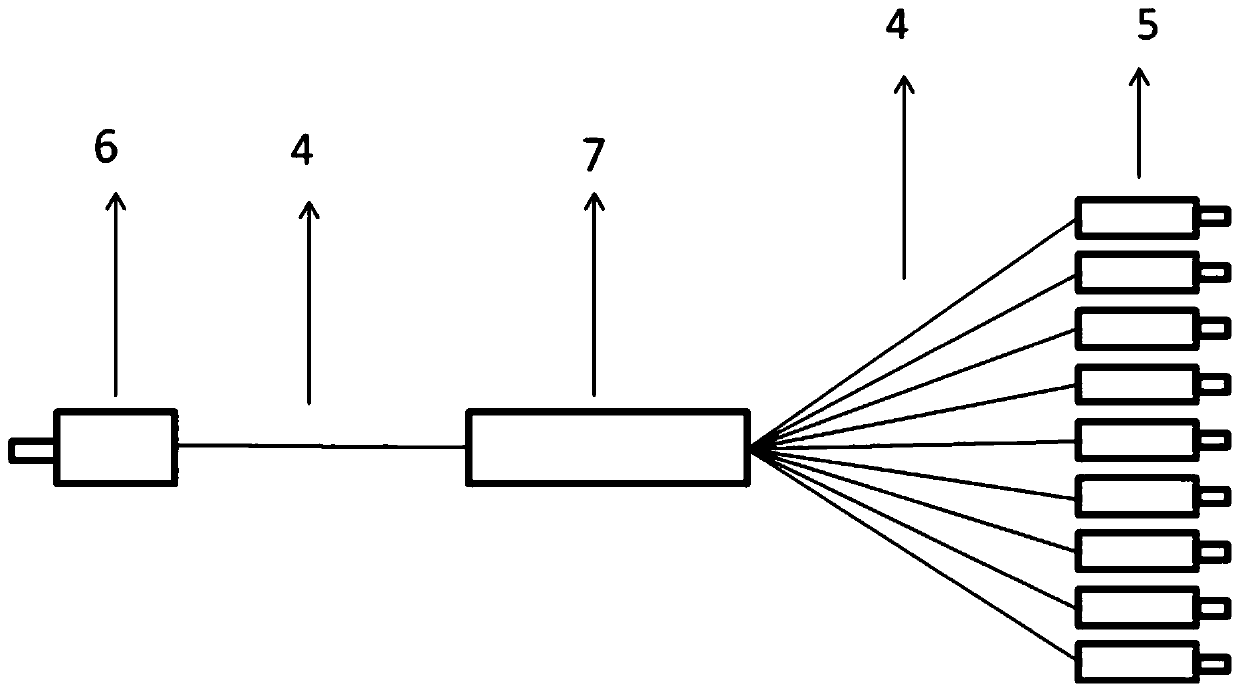

[0062] Handheld fiber optic coupled ultraviolet LED sterilizer and sterilizer for office use and sterilizing method

[0063] 1. Take 100 ultraviolet LED chips with a size of 1mm×1mm, the wavelength is 275nm, the voltage of a single chip is 6V, and the power at 350mA is 50mW. After each chip is packaged, a lens is installed, and a light collimator is installed at the same time.

[0064] 2. After the collimator is connected to the optical fiber, a total of 100 optical fibers are merged into the optical fiber splitter, and then evenly distributed to 100 optical fibers. The ultraviolet LED light coupled by the 100 optical fibers is a collimated parallel point light source. The diameter is about 0.5cm.

[0065] 3. Parallel the ultraviolet LED light coupled from these 100 optical fibers into a straight line to form an ultraviolet light source. The length of the line light source is 50cm.

[0066] 4. The ultraviolet light source made in the above 1-3 steps is integrated in a hand-h...

specific Embodiment 3

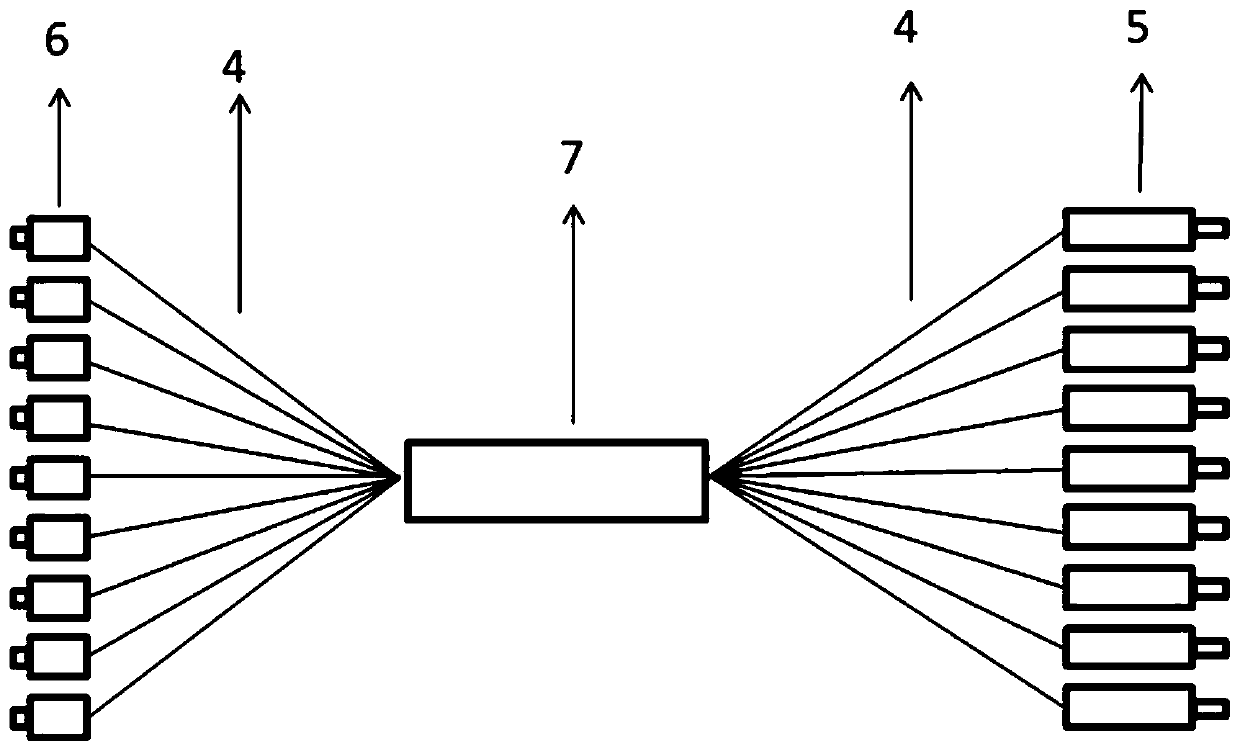

[0071] Mobile optical fiber coupled ultraviolet LED sterilizer and sterilizer for carriage and sterilizing method

[0072] 1. Take 100 ultraviolet LED chips with a size of 1mm×1mm, the wavelength is 275nm, the voltage of a single chip is 6V, and the power at 350mA is 50mW. After each chip is packaged, a lens is installed, and a light collimator is installed at the same time.

[0073] 2. After the collimator is connected to the optical fiber, a total of 100 optical fibers are merged into the optical fiber splitter, and then evenly distributed to 100 optical fibers. The ultraviolet LED light coupled by the 100 optical fibers is a collimated parallel point light source. The diameter is about 0.5cm.

[0074] 3. Parallel the ultraviolet LED light coupled from these 100 optical fibers into a straight line to form an ultraviolet light source. The length of the line light source is 50cm.

[0075] 4. Follow steps 1 to 3 to make another same UV LED light source.

[0076] 5. The ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com