Tellurium catalyst and application thereof in photo-thermal catalytic air disinfection

A catalyst and hydrothermal reaction technology, applied in the field of air purification, can solve the problems of poor catalytic activity and stability, and achieve the effects of excellent light absorption capacity, good stability, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

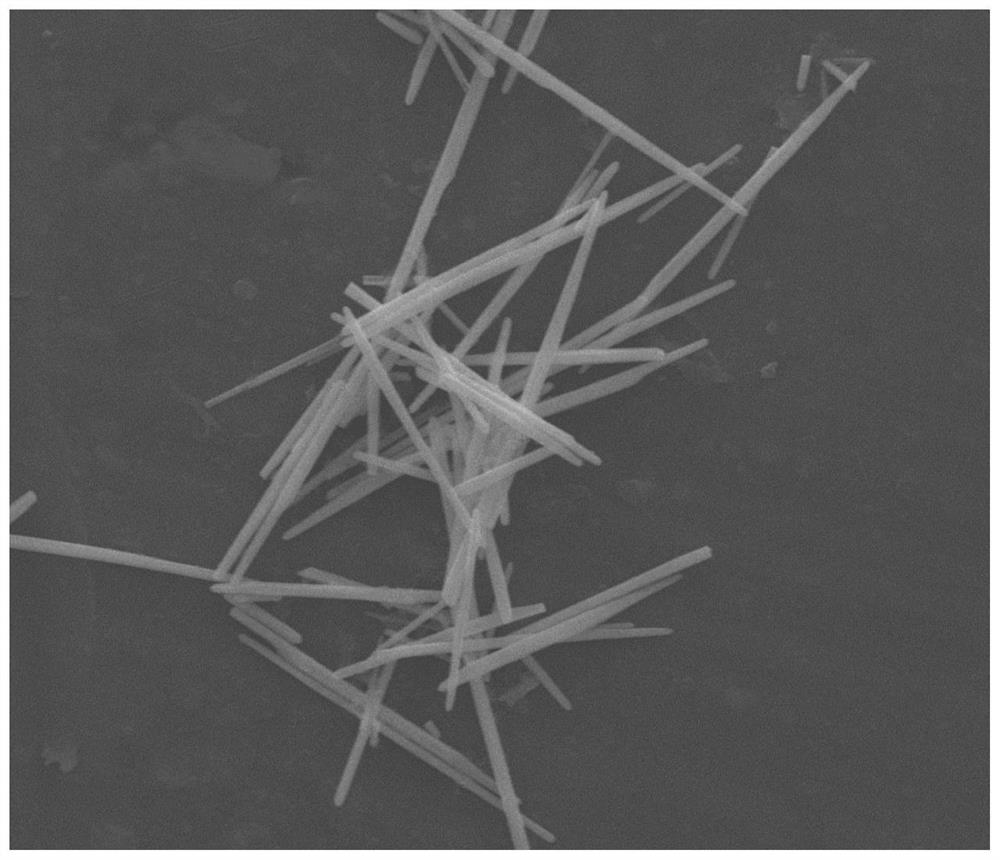

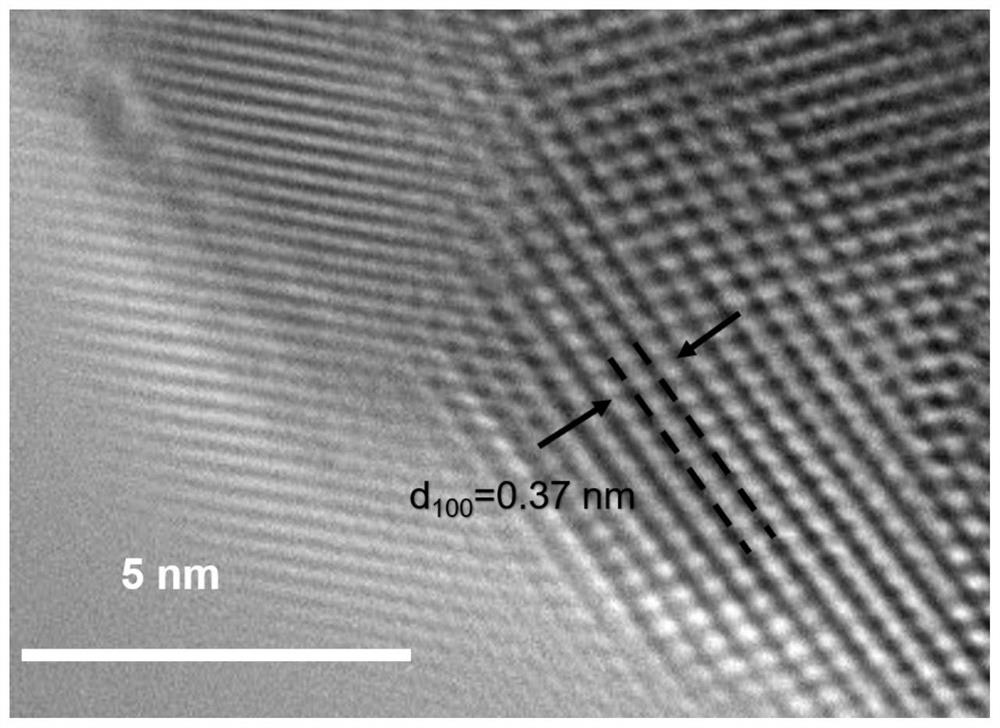

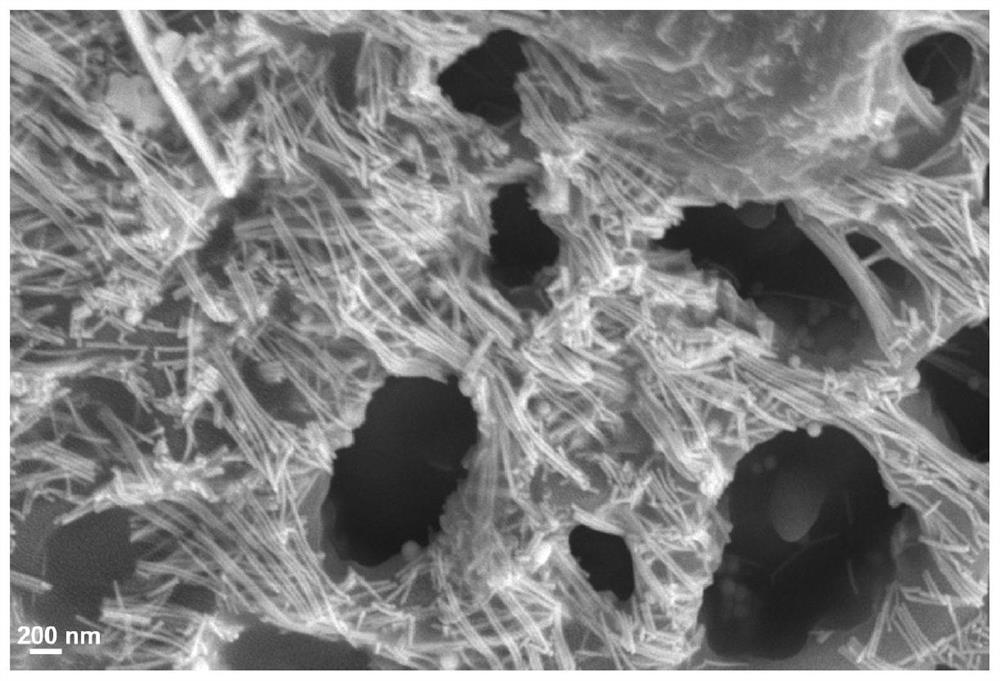

[0078] A kind of tellurium catalyst Te nanowire material Te-8h, concrete preparation method is as follows:

[0079] (1): 160mg sodium tellurite Na 2 TeO 3 Dissolve 1g of polyvinylpyrrolidone (PVP) with a relative molecular weight of 40,000 in 100ml of deionized water, and add 7mL of ammonia water to the mixed solution under magnetic stirring and stir evenly, then add 3mL of hydrazine hydrate solution as a reducing agent , and continued to stir for 1h.

[0080] (2): After the stirring is completed, the mixed solution is transferred to a hydrothermal reaction kettle with a polytetrafluoroethylene lining, and a hydrothermal synthesis reaction occurs in an oven. The hydrothermal temperature is 200 ° C, and the hydrothermal time is 8 hours. When finished, let it cool down to room temperature slowly.

[0081] (3): Then the reaction product is vacuum filtered, and washed repeatedly with pure water until the pH of the cleaning solution is neutral, put it into a vacuum drying oven, ...

Embodiment 2

[0084] A kind of tellurium catalyst Te nanowire material Te-12h, concrete preparation method is as follows:

[0085] (1): 160mg sodium tellurite (Na 2 TeO 3 ) and 1g of polyvinylpyrrolidone (PVP) with a relative molecular weight of 40,000 were dissolved in 100ml of deionized water, and 7mL of ammonia water was first added to the mixed solution under magnetic stirring, and after stirring evenly, 3ml of hydrazine hydrate solution was added as a reduction agent, and kept stirring for 1 h.

[0086] (2): After the stirring is completed, the mixed solution is transferred to a hydrothermal reaction kettle lined with polytetrafluoroethylene, and a hydrothermal synthesis reaction occurs in an oven. The hydrothermal temperature is 200°C, and the hydrothermal time is 12h. When finished, let it cool down to room temperature slowly.

[0087] (3): Then vacuum filter the reaction product, and repeatedly rinse with pure water until the pH of the cleaning solution is neutral, put it into a ...

Embodiment 3

[0090] A tellurium catalyst Te nanowire material Te-16h, the specific preparation method is as follows:

[0091] (1): 160mg sodium tellurite (Na 2 TeO 3 ) and 1g of polyvinylpyrrolidone (PVP) with a relative molecular weight of 40,000 were dissolved in 100ml of deionized water, and 7mL of ammonia water was first added to the mixed solution under magnetic stirring, and after stirring evenly, 3mL of hydrazine hydrate solution was added as a reduction agent, and kept stirring for 1 h.

[0092] (2): After the stirring is completed, the mixed solution is transferred to a hydrothermal reaction kettle with a polytetrafluoroethylene lining, and a hydrothermal synthesis reaction occurs in an oven. The hydrothermal temperature is 200 ° C, and the hydrothermal time is 16 hours. When finished, let it cool down to room temperature slowly.

[0093] (3): Then vacuum filter the reaction product, and repeatedly rinse with pure water until the pH of the cleaning solution is neutral, put it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Optical power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com