Graphene vertical ordered array doped with heteroatoms and preparation method and application thereof

A vertically ordered, graphene technology, applied in chemical instruments and methods, electrodes, electrolysis processes, etc., can solve problems such as research reports on vertical arrays of doped graphene, etc., to increase effective exposure, promote diffusion, and conduct electricity. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Add 60 mg of graphene oxide and 300 mg of boric acid into 10 mL of deionized water for ultrasonic dispersion for 1 h to form a mixed dispersion with a concentration of graphene oxide of 6 mg / mL.

[0050] (2) After mixing 0.3mL of ethanol and 10mL of graphene dispersion, continue ultrasonication for 1h to obtain a mixed solution;

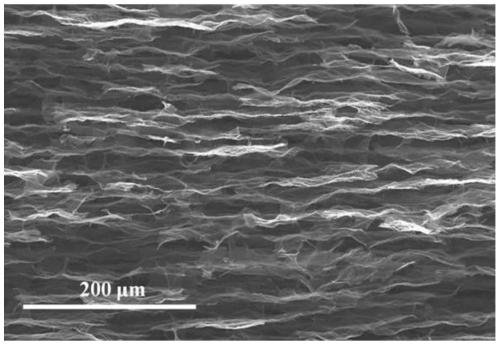

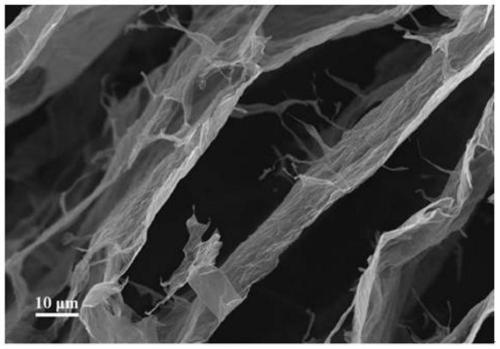

[0051] (3) The mixed solution obtained in step (2) was frozen with liquid nitrogen in a bottom-up manner, and after being completely frozen, it was put into a freeze dryer to dry for 48 hours.

[0052] (4) Put the graphene airgel formed after freeze-drying into a tube furnace protected by an argon atmosphere, at a heating rate of 10°C / min, 200°C for 2h, 1000°C for 3h, and finally in an argon atmosphere The temperature is lowered in the middle, and the vertical ordered array of graphene doped with B atoms is prepared.

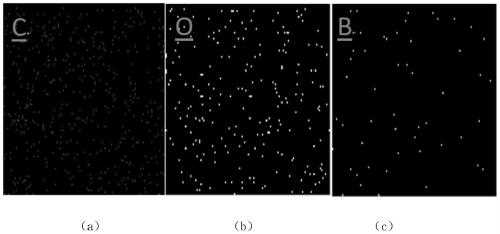

[0053] The content of graphene prepared in this embodiment is 78.56wt%, the content of oxygen atoms is 13.42wt%, and the ...

Embodiment 2

[0062] (1) Dissolve 60 mg of graphene oxide and 60 mg of urea in 10 mL of deionized water, and ultrasonically disperse for 1 hour to form a mixed dispersion with a graphene oxide concentration of 6 mg / mL.

[0063](2) After adding 0.3 mL of ethanol and 10 mL of graphene dispersion and mixing, continue ultrasonication for 1 h to obtain a mixed solution.

[0064] (3) The mixed solution obtained in (2) was frozen in a bottom-up manner with liquid nitrogen, and then put into a freeze dryer to dry for 48 hours after freezing completely.

[0065] (4) Put the graphene airgel formed after freeze-drying into a tube furnace protected by an argon atmosphere, at a heating rate of 10°C / min, 200°C for 2h, 700°C for 3h, and finally in an argon atmosphere The temperature is lowered in the middle, and the vertical ordered array of graphene doped with N atoms is prepared.

[0066] The graphene vertical ordered array prepared by this embodiment is carried out X-ray photoelectron energy spectrum,...

Embodiment 3

[0068] (1) Add 50 mg of graphene oxide into 10 mL of deionized water and ultrasonically disperse for 1 h to form a graphene oxide dispersion with a concentration of 5 mg / mL.

[0069] (2) Add 300 μL of methanol and 1 μL of phytic acid (35 wt.%) into the above graphene dispersion and continue ultrasonication for 1 h.

[0070] (3) The mixed solution was frozen with liquid nitrogen in a bottom-up manner, and after freezing, put it into a freeze dryer to dry for 48 hours.

[0071] (4) Put the graphene airgel formed after freeze-drying into a tube furnace, heat reduction at a high temperature at a rate of 10°C / min under an argon atmosphere, continue at 200°C for 2h, and continue at 800°C for 3h, and finally The temperature is lowered in an argon atmosphere, and a vertical ordered array of graphene doped with P atoms is prepared.

[0072] The graphene vertical ordered array prepared by this embodiment is carried out X-ray energy spectrum analysis, the result is as follows Figure 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com