Cu-CHA and H-AEI composite catalyst and preparation method and application thereof

A composite catalyst, SCR catalyst technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of complex preparation methods, poor hydrothermal stability, and high preparation costs, and achieve simple preparation methods. The effect of strong thermal stability and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

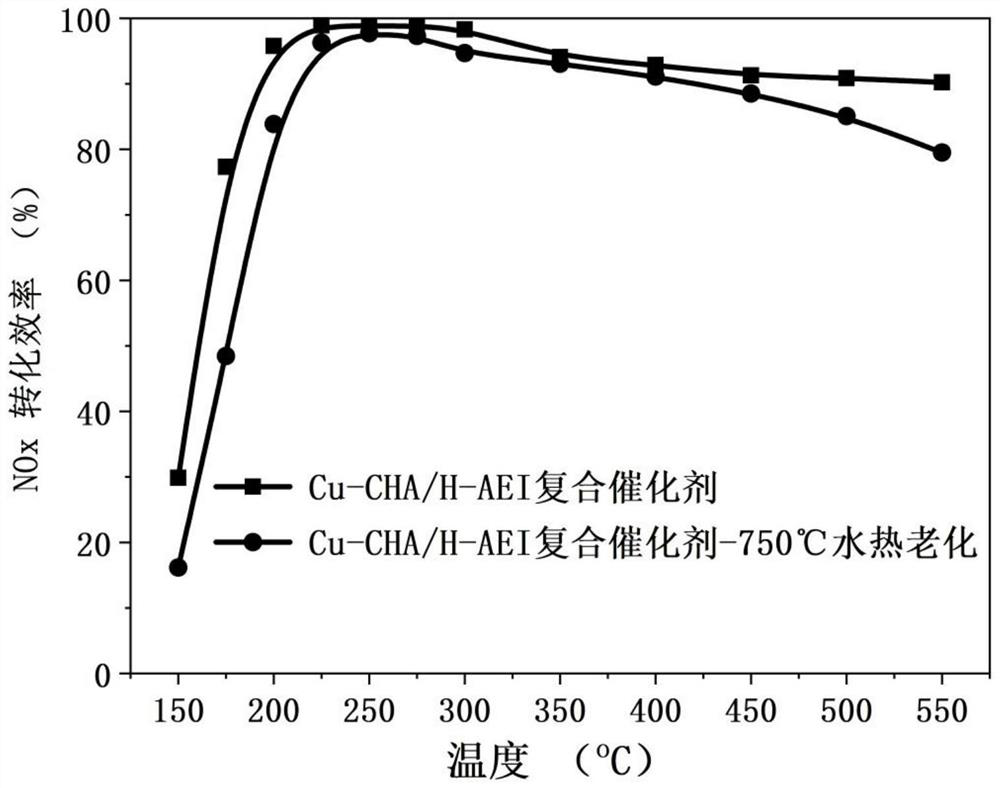

[0054] This embodiment provides a composite catalyst of Cu-CHA and H-AEI, and the composite catalyst comprises Cu-CHA zeolite with a mass ratio of 27:3 and SSZ-39 hydrogen zeolite with AEI structure type (H-AEI zeolite).

[0055] The preparation method of the composite zeolite SCR catalyst comprises:

[0056] The composite catalyst is obtained by grinding and mixing Cu-CHA zeolite and H-AEI zeolite;

[0057] Based on the mass of Cu-CHA zeolite, the mass fraction of Cu in the Cu-CHA zeolite is 4.2%, and the molar ratio of silica to alumina is 9:1; The molar ratio of alumina was 20:1.

[0058] The preparation method of the Cu-CHA zeolite comprises the following steps:

[0059] (1) Stir and mix the SSZ-13 hydrogen-type zeolite with a structure type of CHA and an ammonium chloride solution with a concentration of 0.2 mol / L at a speed of 500 rpm at 30 °C, and the solid state of the SSZ-13 hydrogen-type zeolite and the ammonium chloride solution. The liquid ratio is 1:20, and th...

Embodiment 2

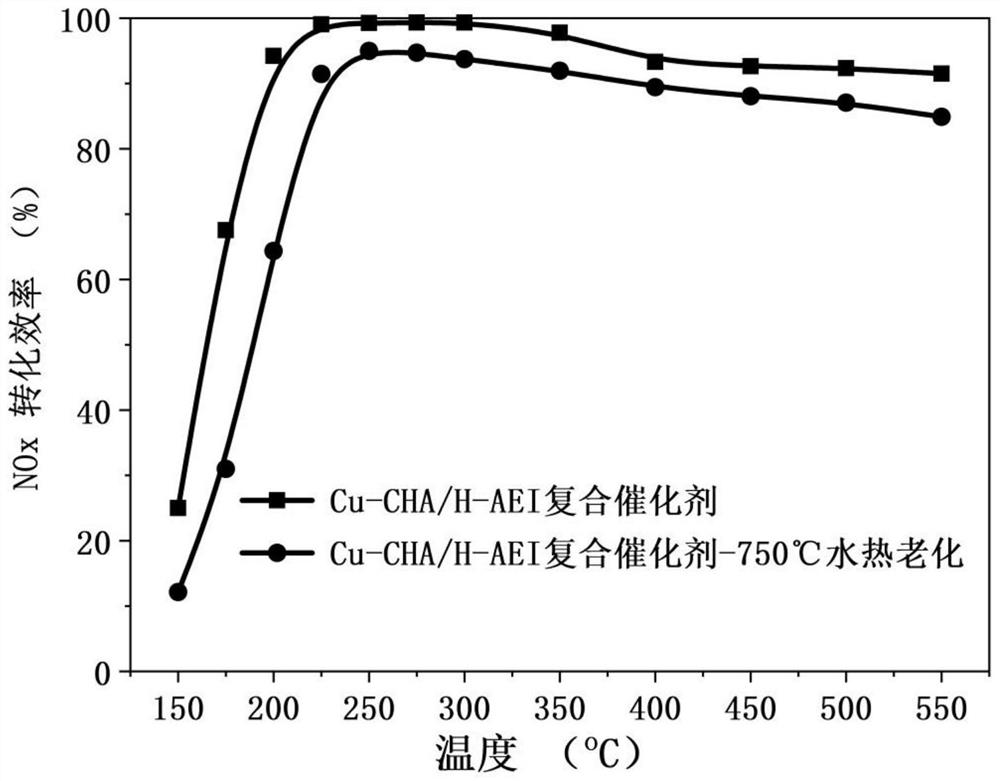

[0062] This embodiment provides a composite catalyst of Cu-CHA and H-AEI, and the composite catalyst comprises Cu-CHA zeolite with a mass ratio of 60:3 and SSZ-39 hydrogen zeolite with AEI structure type (H-AEI zeolite).

[0063] The preparation method of the composite zeolite SCR catalyst comprises:

[0064] The composite catalyst is obtained by grinding and mixing Cu-CHA zeolite and H-AEI zeolite;

[0065] Based on the mass of Cu-CHA zeolite, the mass fraction of Cu in the Cu-CHA zeolite is 2.4%, and the molar ratio of silica to alumina is 20:1; The molar ratio of alumina was 25:1.

[0066] The preparation method of the Cu-CHA zeolite comprises the following steps:

[0067] (1) Stir and mix the SSZ-13 hydrogen-type zeolite with a structure type of CHA and an ammonium chloride solution with a concentration of 0.18 mol / L at a speed of 600 rpm at 50 °C, and the solid state of the SSZ-13 hydrogen-type zeolite and the ammonium chloride solution. The liquid ratio is 1:25, and th...

Embodiment 3

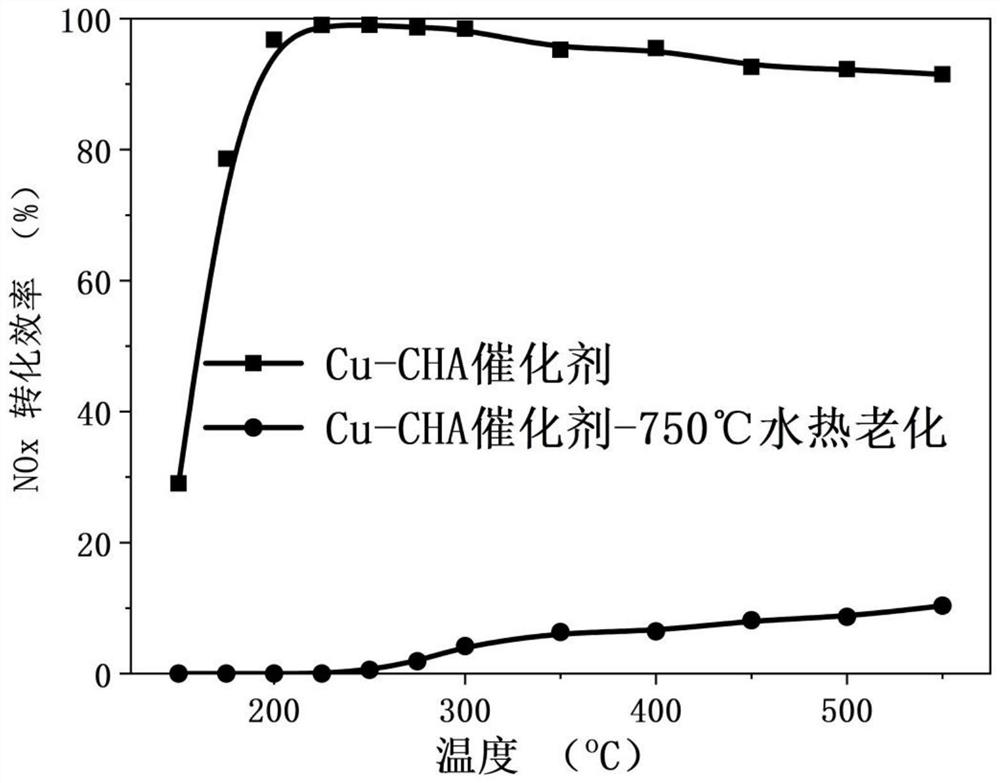

[0070] This embodiment provides a composite catalyst of Cu-CHA and H-AEI, the composite catalyst comprises Cu-CHA zeolite with a mass ratio of 7:3 and SSZ-39 hydrogen zeolite with AEI structure type (H-AEI zeolite).

[0071] The preparation method of the composite zeolite SCR catalyst comprises:

[0072] The composite catalyst is obtained by grinding and mixing Cu-CHA zeolite and H-AEI zeolite;

[0073] Based on the mass of Cu-CHA zeolite, the mass fraction of Cu in the Cu-CHA zeolite is 5.6%, and the molar ratio of silica to alumina is 12:1; The molar ratio of alumina was 40:1.

[0074] The preparation method of the Cu-CHA zeolite comprises the following steps:

[0075] (1) Stir and mix the SSZ-13 hydrogen-type zeolite with a structure type of CHA and an ammonium chloride solution with a concentration of 0.13 mol / L at a speed of 400 rpm at 40 °C, and the solid state of the SSZ-13 hydrogen-type zeolite and the ammonium chloride solution. The liquid ratio is 1:30, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com