Non-sticky intraocular lens and method for making the same

An intraocular lens, a technology that is not easy to use, applied in the direction of intraocular lens, prosthesis, coating, etc., can solve the problems of insufficient resilience of materials, difficulty in climbing, and low rate of natural expansion, etc., to achieve enhanced resilience and enhanced resilience , the effect of enhancing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

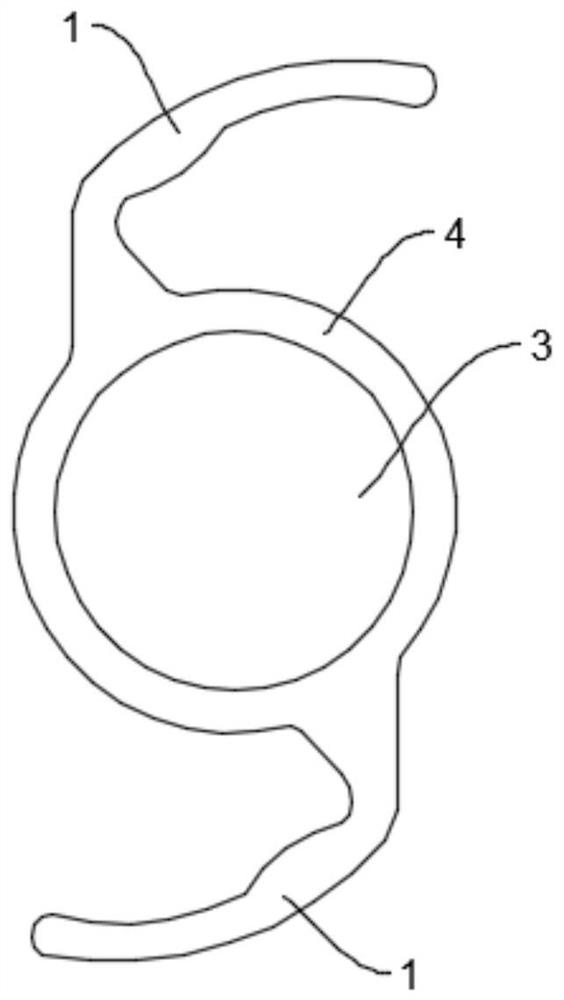

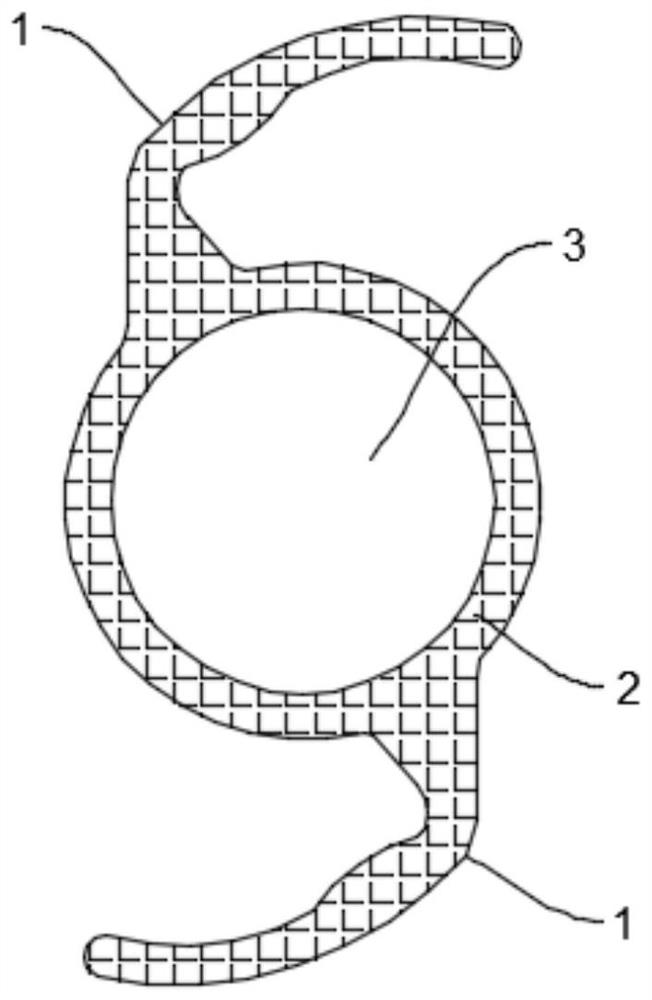

[0041] like figure 1 , figure 2 As shown, the present embodiment provides an intraocular lens that is not easy to stick and climb, including a lens-like main body and a supporting plate 1. At least two supporting plates 1 extend radially along the edge of the crystal-like main body. Woven fibre structure 2 or metal foil type material.

[0042] Because the braided fiber structure 2 or metal foil-type material is embedded in the support plate 1 in this technical solution, the resilience of the corresponding part of the intraocular lens can be enhanced, and the toughness of the structure can be enhanced, so that when the support plate 1 is unfolded, the resilience is enhanced and reduced. The possibility of sticking to the support 1 allows the intraocular lens to be unfolded smoothly after entering the lens capsular bag, even if different people have different operating techniques, different IOL sizes, different bolus tubes, and curled IOLs. Different methods, different length...

Embodiment 2

[0044] This embodiment is optimized on the basis of the above-mentioned Embodiment 1.

[0045] The crystal-like body includes a central optical zone 3 and an annular edge zone 4 around the central optical zone 3, and the annular edge zone 4 is embedded with a woven fiber structure 2 or a metal foil type material.

[0046] It should be noted that the woven fiber structure 2 or the metal foil type material can be arranged in a circle along the annular edge region 4, and can also be arranged in an arc-shaped structure with less than one circle.

Embodiment 3

[0048] The present invention also provides a method for making an intraocular lens that is not easy to stick to, comprising the following steps:

[0049] S1. Prepare a mixture of fiber material and intraocular lens material;

[0050] The fiber material is 40% polyurethane fiber;

[0051] The intraocular lens material mixture comprises the following components by mass content: 30% of phenethyl acrylate, 65% of phenethyl methacrylate, 3% of ethylene glycol diacrylate and 2% of AIBN;

[0052] S2. Weaving 40um 40% polyurethane fiber into a sheet to form a woven fiber sheet;

[0053] S3, cutting the woven fiber sheet into an intraocular lens shape to form a woven fiber structure;

[0054] S4, 1) cleaning the braided fiber structure: cleaning the braided fiber structure by ultrasonic ethanol and deionized water for 2 minutes respectively;

[0055] 2) drying and cleaning the braided fiber structure: drying the cleaned braided fiber structure at a temperature of 60 degrees to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com