A kind of preparation method of superhydrophilic PTFE filter membrane and the superhydrophilic PTFE filter membrane that adopts this preparation method to make

A technology of PTFE and filter membrane, which is applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problems of poor stability of hydrophilic modification, loss of hydrophilic effect, and influence of coating fastness, etc., achieving excellent stability, The effect of improving hydrophilicity and improving firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

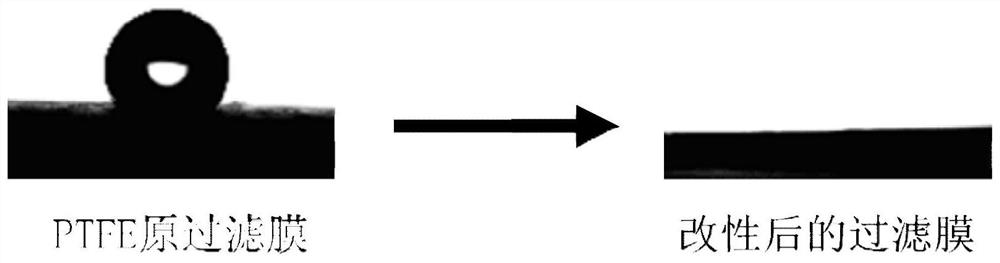

[0024] (1) Immerse the PTFE filter membrane (0.22 μm in pore size and 150 μm in thickness) in the ammonia solution containing dopamine and PEI, wherein the concentration of dopamine in the ammonia solution is 2 mg / ml, the concentration of PEI is 1 mg / ml, and the ammonia solution The pH is 8.5;

[0025] (2) G-POSS tetrahydrofuran solution is added in above-mentioned ammonia solution to obtain mixed solution, wherein, the volume ratio of G-POSS tetrahydrofuran solution and ammonia solution is 20:250, and the concentration of G-POSS in mixed solution is 1mg / ml;

[0026] (3) After stirring at room temperature for 24 hours, add copper sulfate to the above mixed solution, and then stir at room temperature for 6 hours, wherein the concentration of copper sulfate in the mixed solution is 40mg / ml;

[0027] (4) Take out the PTFE filter membrane, dry at room temperature after cleaning with deionized water, obtain the required super-hydrophilic PTFE filter membrane.

Embodiment 2

[0029] (1) Immerse the PTFE filter membrane (0.1 μm in pore size and 100 μm in thickness) in an ammonia solution containing dopamine and PEI, wherein the concentration of dopamine in the ammonia solution is 1 mg / ml, the concentration of PEI is 2 mg / ml, and the ammonia solution The pH is 8.5;

[0030] (2) G-POSS tetrahydrofuran solution is added in above-mentioned ammonia solution to obtain mixed solution, wherein, the volume ratio of G-POSS tetrahydrofuran solution and ammonia solution is 20:100, and the concentration of G-POSS in mixed solution is 4mg / ml;

[0031] (3) After stirring at room temperature for 10 hours, add copper sulfate to the above mixed solution, and then stir at room temperature for 1 hour, wherein the concentration of copper sulfate in the mixed solution is 40 mg / ml;

[0032] (4) Take out the PTFE filter membrane, dry at room temperature after cleaning with deionized water, obtain the required super-hydrophilic PTFE filter membrane.

Embodiment 3

[0034] (1) Immerse the PTFE filter membrane (0.22 μm in pore size and 200 μm in thickness) in an ammonia solution containing dopamine and PEI, wherein the concentration of dopamine in the ammonia solution is 4 mg / ml, the concentration of PEI is 2 mg / ml, and the ammonia solution The pH is 8;

[0035] (2) G-POSS tetrahydrofuran solution is added in above-mentioned ammonia solution to obtain mixed solution, wherein, the volume ratio of G-POSS tetrahydrofuran solution and ammonia solution is 20:200, and the concentration of G-POSS in mixed solution is 5mg / ml;

[0036] (3) After stirring at room temperature for 12 hours, add copper sulfate to the above mixed solution, and then stir at room temperature for 6 hours, wherein the concentration of copper sulfate in the mixed solution is 50 mg / ml;

[0037] (4) Take out the PTFE filter membrane, dry at room temperature after cleaning with deionized water, obtain the required super-hydrophilic PTFE filter membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com