Cylindrical lithium ion battery transferring and clamping system

A technology of lithium-ion batteries and transfer clips, applied in the direction of internal accessories, etc., can solve the problems of inconvenient clamping of cylindrical lithium batteries, achieve the effect of increasing viscosity, reducing the probability of falling, and ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

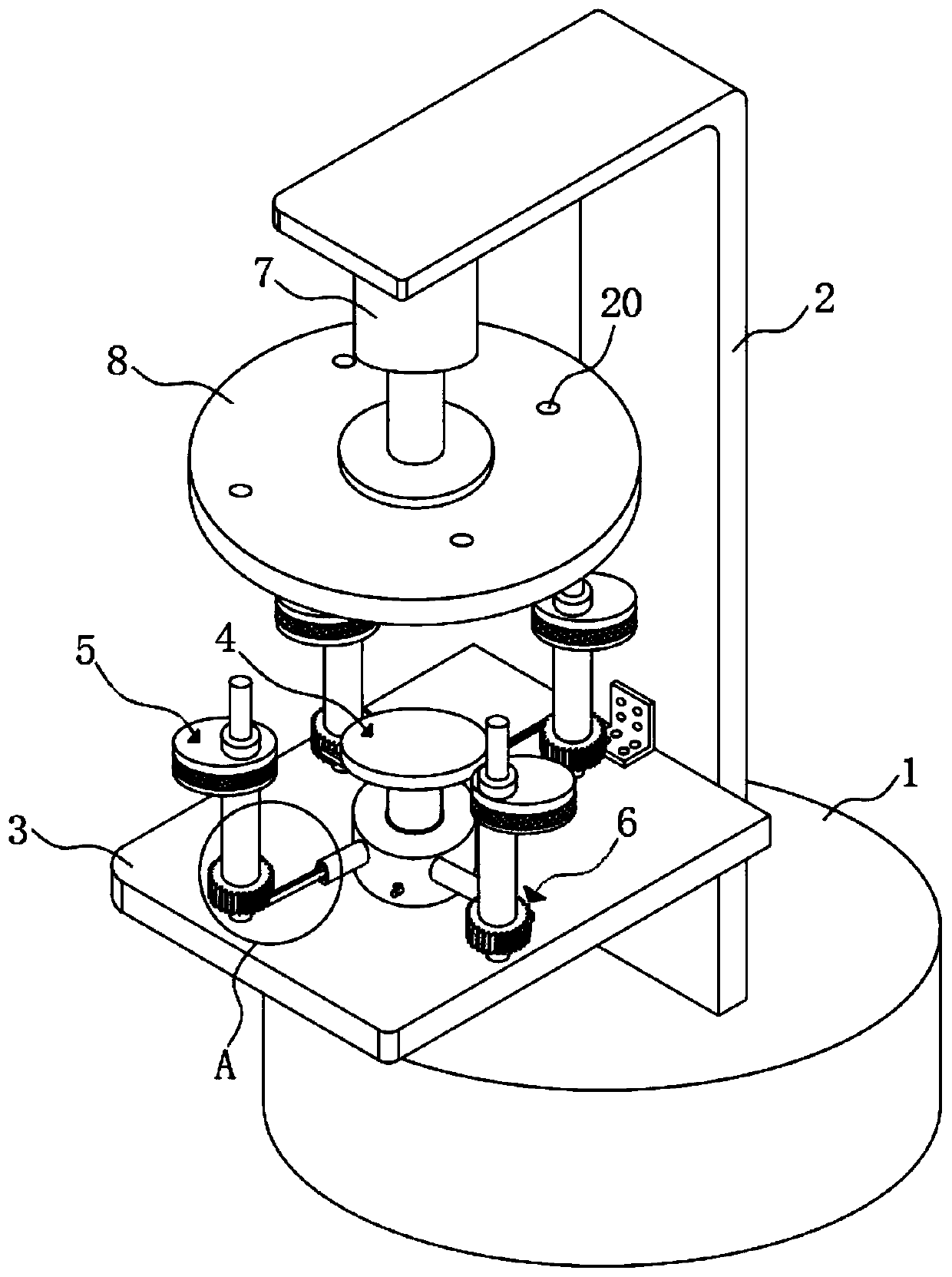

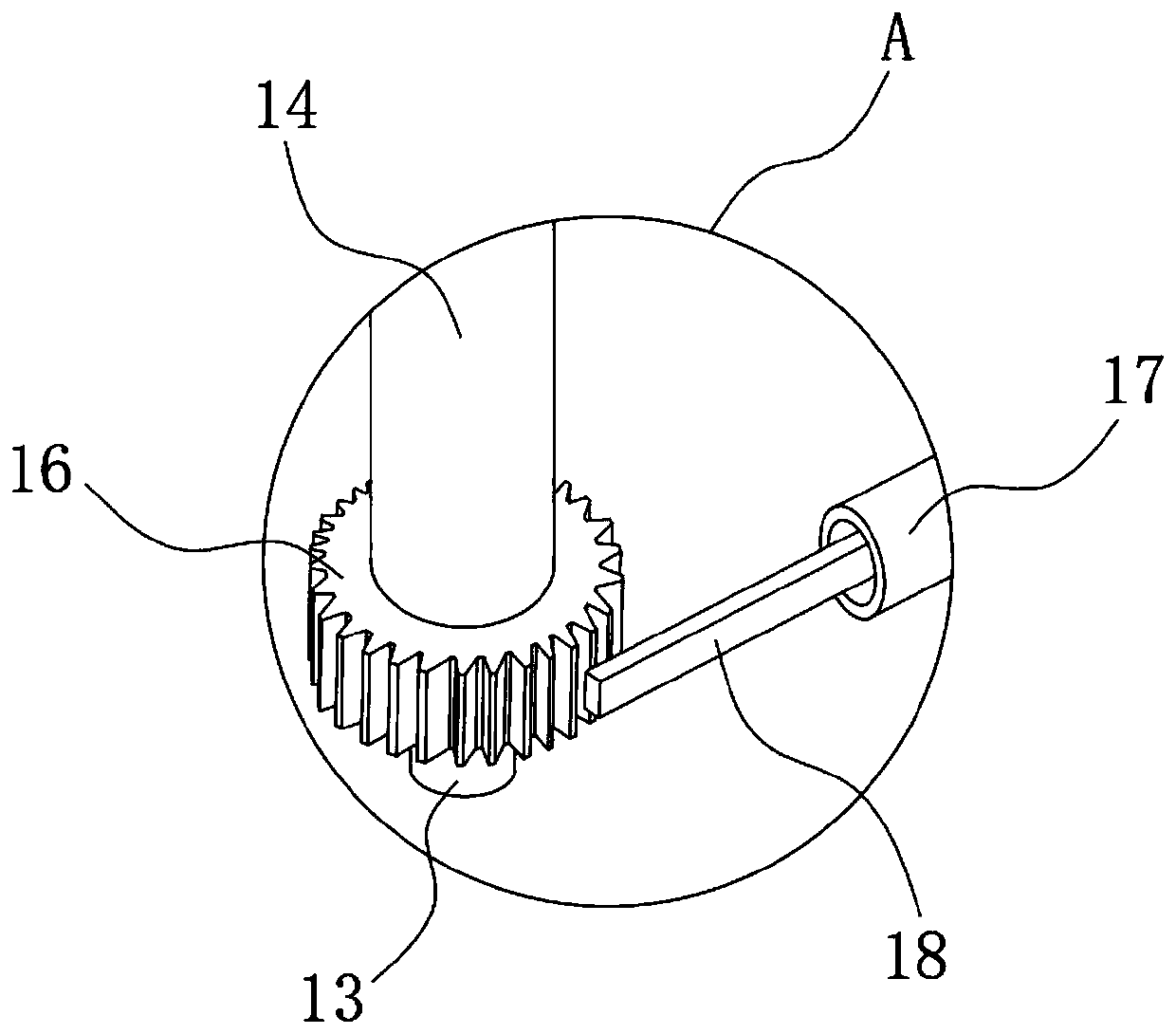

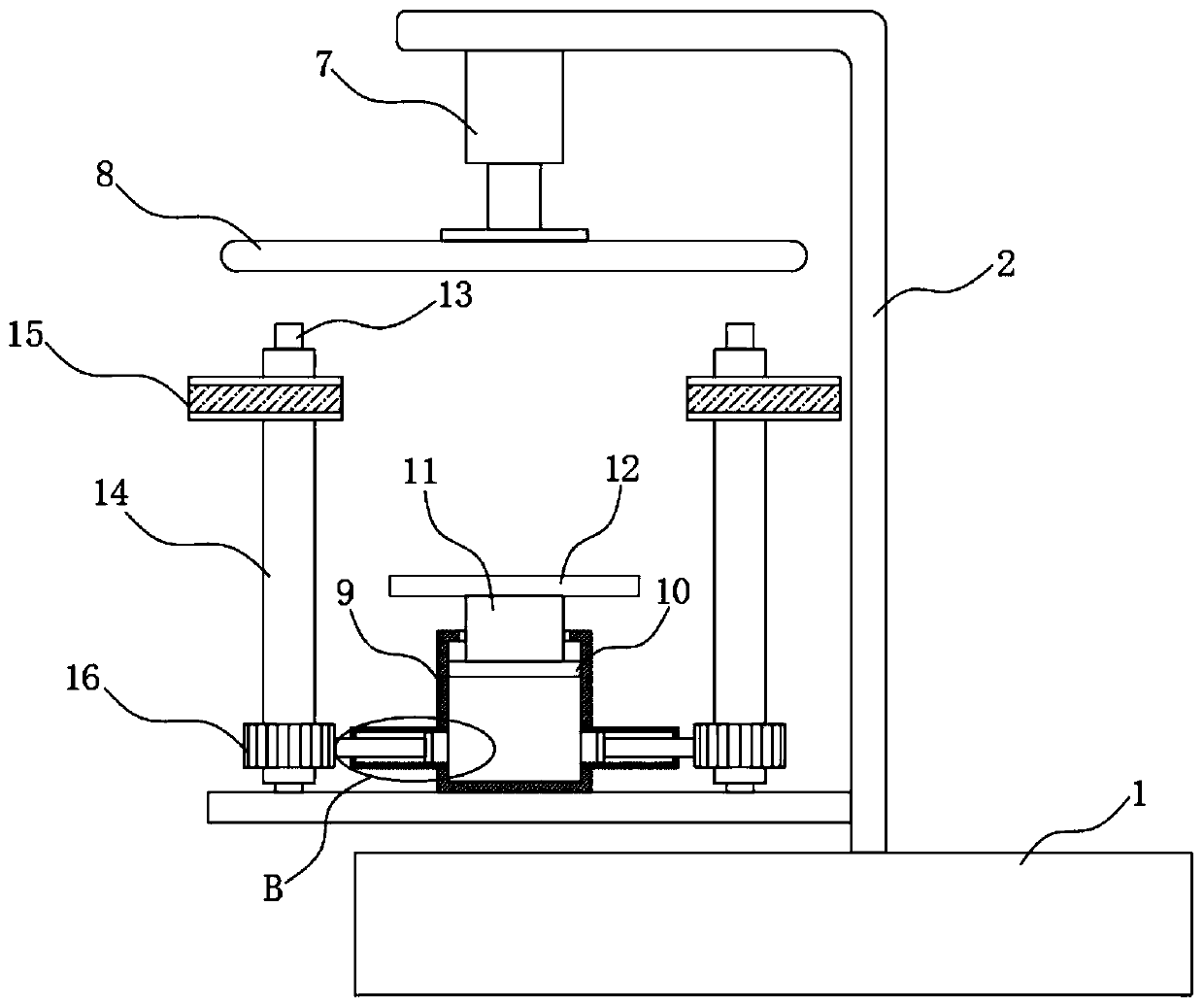

[0025] Such as Figure 1-4 As shown, a cylindrical lithium-ion battery transfer and clamping system includes a mobile seat 1 with rollers installed at the bottom, an L-shaped fixed plate 2 is fixedly connected to the upper end of the mobile seat 1, and a fixed plate 2 is fixedly connected to the side wall of the fixed plate 2. The supporting plate 3, the supporting plate 3 and the fixed plate 2 are connected by a connecting piece, the upper end of the supporting plate 3 is fixedly connected with a placement seat 4, and clamping parts 5 are arranged around the placement seat 4, and the lithium battery is placed on the placement seat 4, the placement seat 4 will drive the clamping parts 5 through the transmission mechanism 6 to jointly clamp the lithium battery, the top of the fixed plate 2 is fixedly connected with a hydraulic cylinder 7, and the lower end of the hydraulic cylinder 7 is fixedly connected with a pressure plate 8;

[0026] The placement seat 4 includes a hollow c...

Embodiment 2

[0033] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that: the lower end of the pressing plate 8 and the upper end of the placement plate 12 are fixedly connected with electrode sheets 21, and the two electrode sheets 21 are electrically connected, and the cylindrical part 9 is filled with There is electrorheological fluid, which is a suspension under normal conditions, and it can undergo a liquid-solid transition under the action of an electric field. When the applied electric field strength is much lower than a certain critical value, the electrorheological fluid is in a liquid state ; When the electric field strength is much higher than this critical value, it becomes solid, and the viscosity of this suspension becomes larger with the increase of the electric field strength.

[0034] In this embodiment, after the lithium battery is fixed and the pressing plate 8 is pressed on it, the conduction circuit of the lithium battery starts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com