Microcrystalline glass and multilayer inorganic film filter

A technology of glass-ceramic and inorganic film, which is applied in the direction of waveguide devices, electrical components, circuits, etc., can solve the problems of low thermal expansion of amorphous glass, poor film-forming property, and poor heat resistance of plastics, so as to avoid the refractive index Effects of changes, improved temperature stability, and good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

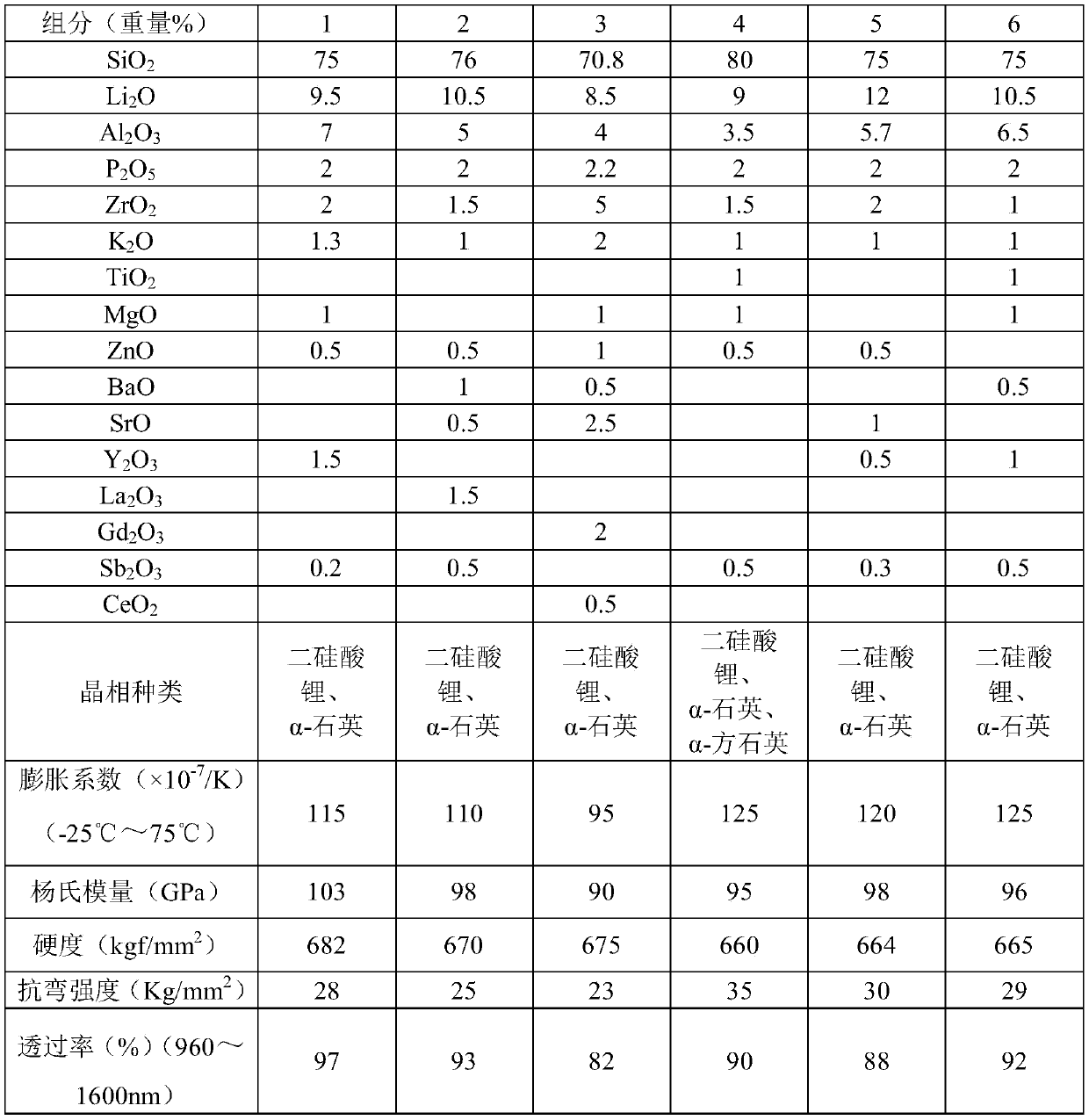

[0031] The reasons why the substrate glass-ceramics of the multilayer inorganic membrane filter of the present invention limit its composition and content, as well as its expansion coefficient, Young's modulus, hardness, bending strength, transmittance and main crystal phase are described below.

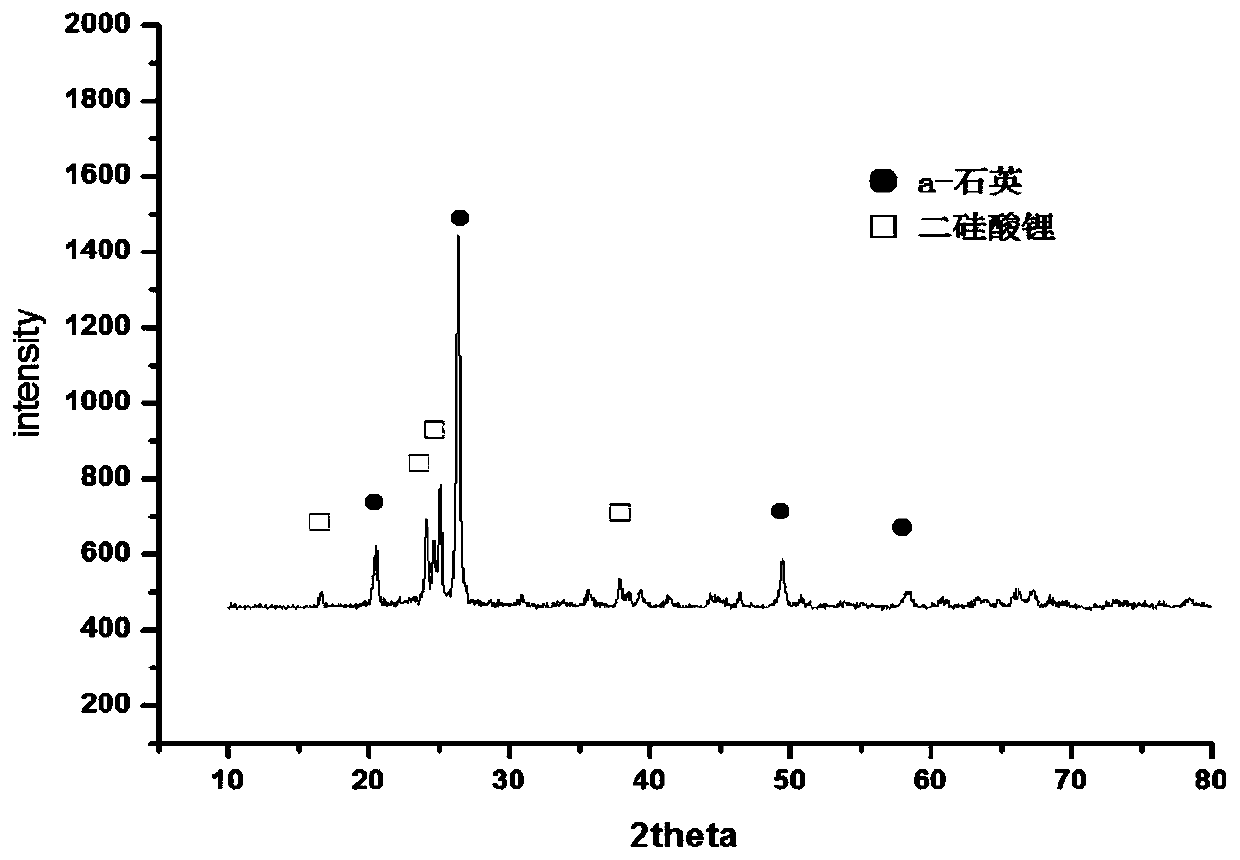

[0032] The glass substrate of the multilayer inorganic film filter provided by the invention is based on LiO 2 -Al 2 o 3 -SiO 2 Glass-ceramic for the system.

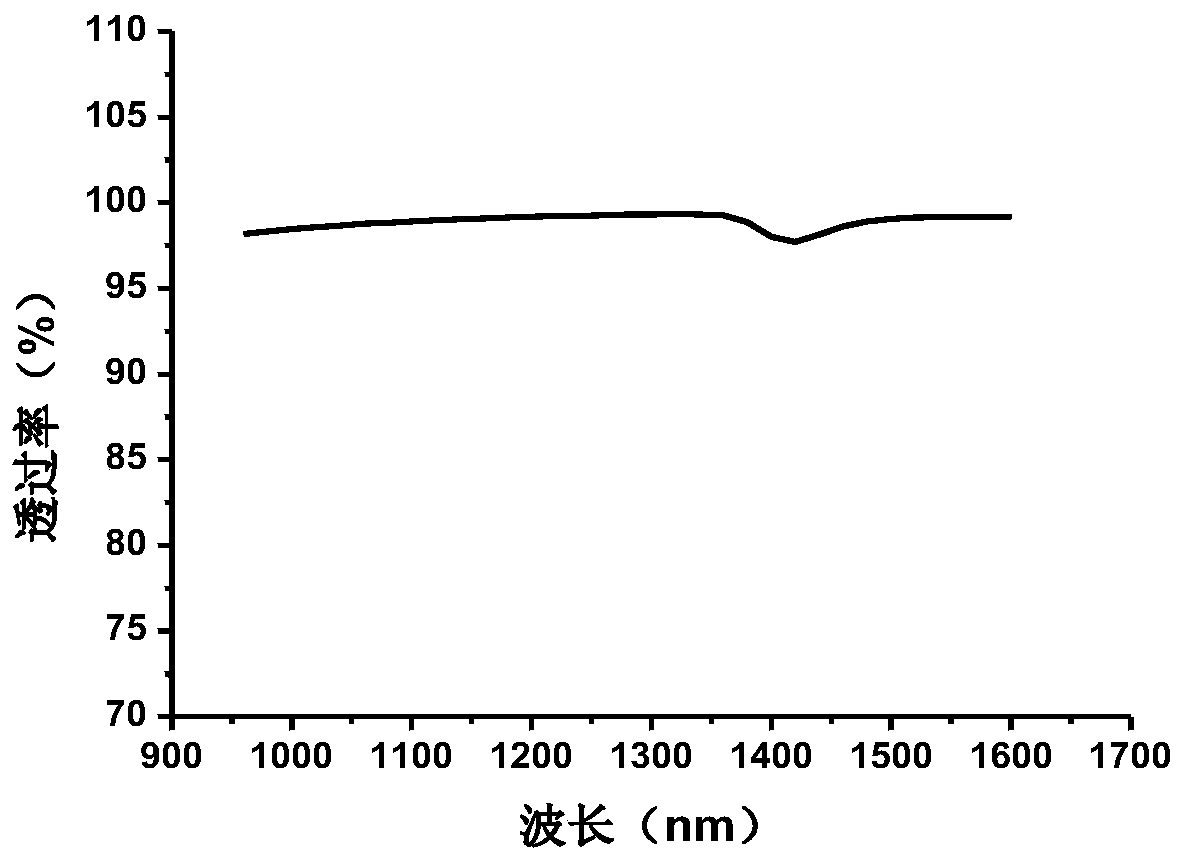

[0033] The glass-ceramics of the substrate material of the multilayer inorganic membrane filter provided by the present invention has an expansion coefficient of 90×10 in the temperature range of -25°C to 75°C. -7 / ℃~130×10 -7 / °C range, preferably 110~120×10 -7 / °C range. In the bandpass filter, the temperature stability of the central wavelength is related to the temperature coefficient of the refractive index of the multilayer inorganic thin film. The refractive index is determined by the atomic density of the film on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| swell index | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| visible light transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com