Biogas slurry and biogas residue multi-stage treatment device and method

A processing device and biogas residue technology, which is applied in the directions of organic fertilizers and climate change adaptation, can solve the problems of difficult promotion of biogas fermentation, and achieve the effect of reasonable overall structure design and avoiding foul odors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

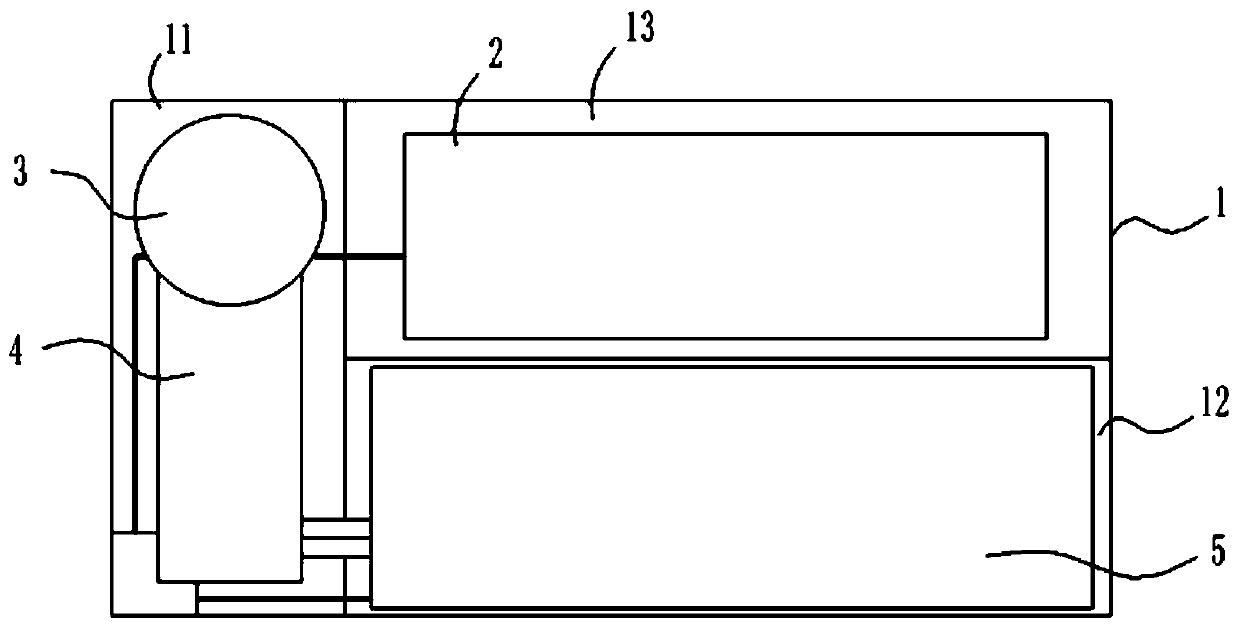

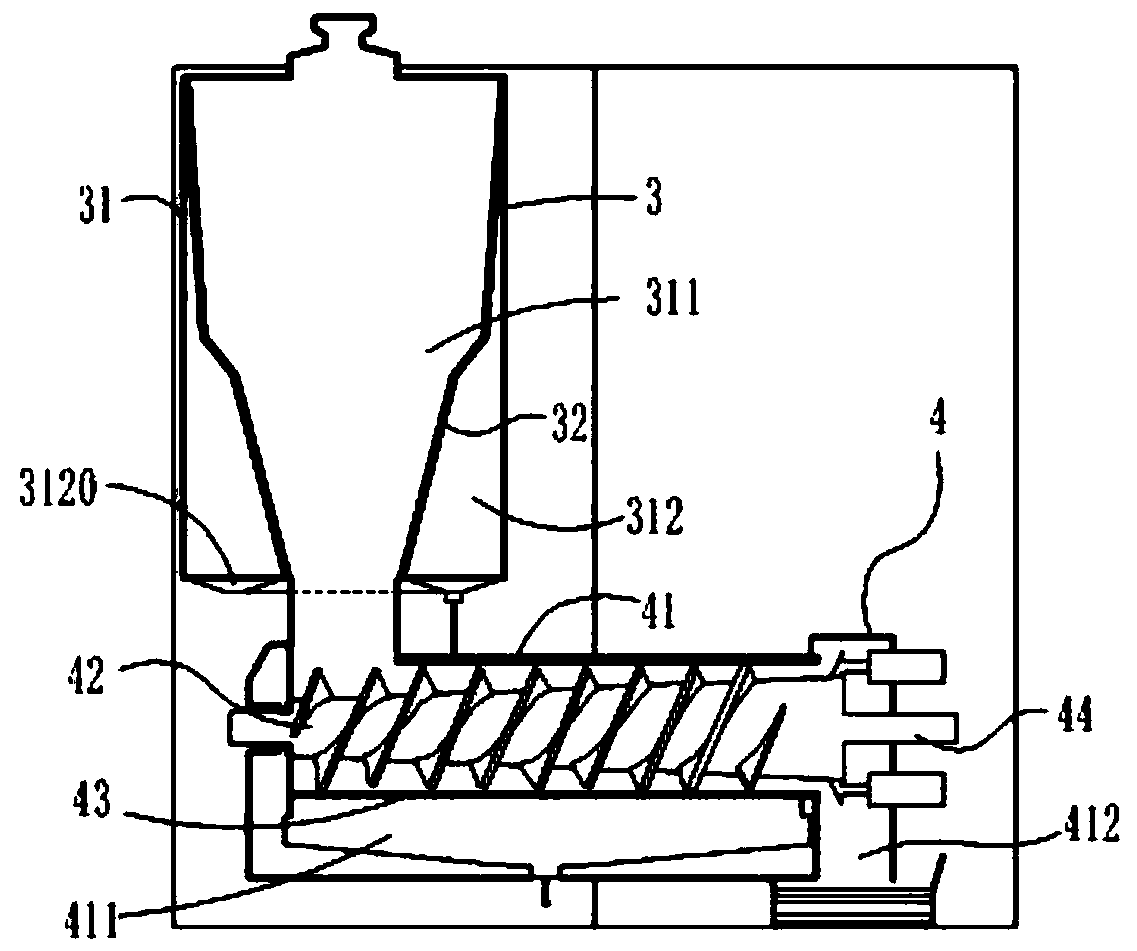

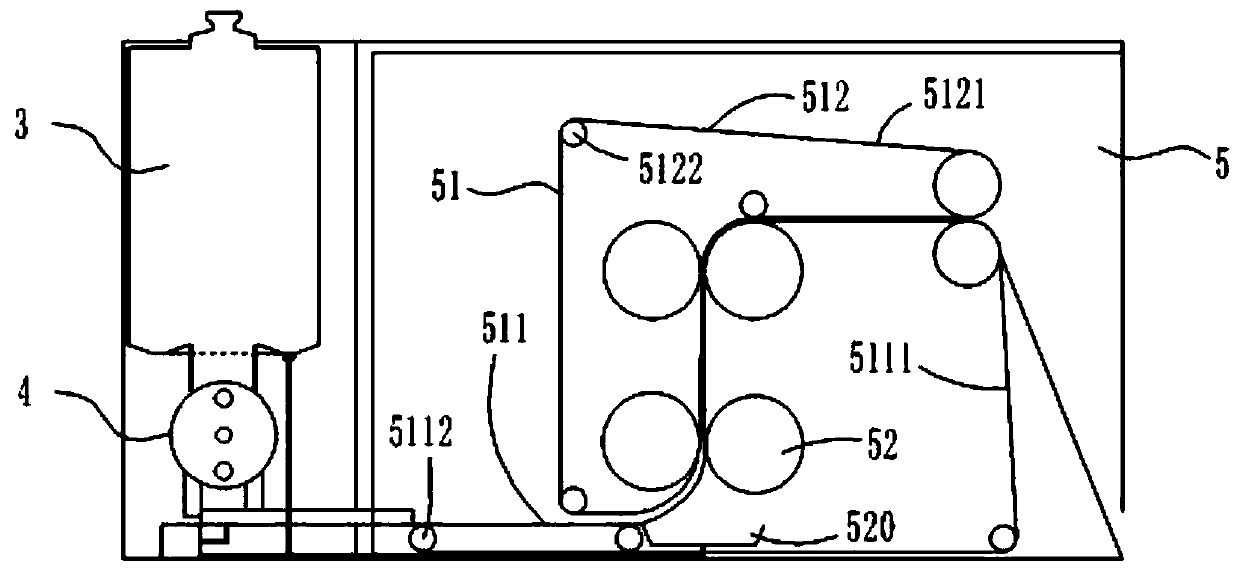

[0036] Embodiment 1: as figure 1 , 2 A biogas slurry and biogas slag multi-stage treatment device shown in . 1 Internally used for solid-liquid separation equipment to further ferment the liquid treated with biogas residue and biogas slurry 2; the equipment shell 1 includes a first cavity 11, a second cavity 12, a third cavity 13, and the second cavity The second cavity 12 and the third cavity 13 are arranged side by side to form a connecting cavity, and the first cavity 11 is arranged side by side with the connecting cavity;

[0037] The solid-liquid separation equipment includes a first separation equipment 3, a second separation equipment 4, and a third separation equipment 5 connected in sequence;

[0038] Such as figure 1 , 2 As shown, the first separation device 3 is installed in the first cavity 11; the first separation device 3 includes a cylindrical feed tank 31, and a first filter assembly 32 arranged inside the feed tank 31; the first filter The component 32 divi...

Embodiment 2

[0045] Embodiment 2: Different from Embodiment 1: as Figure 4 , 5 As shown, the first separation device 3 also includes an auxiliary filter assembly 33 for buffering. The auxiliary filter assembly 33 is installed on the feed tank 31 and is located inside the solid chamber 311; The first installation assembly 331 on the top, and the first slow flow plate assembly 332 arranged at the lower end of the first installation assembly 331; the first slow flow plate assembly 332 includes three first buffer plates 3321, and is used for three first buffer plates The first connecting rod 3322 connected between the plates 3321; the first installation component 331 adopts 2 sets of hanging steel ropes;

Embodiment 3

[0046] Embodiment 3: Different from Embodiment 1: as Figure 6 , 7 As shown, the first separation device 3 also includes an auxiliary filter assembly 33 for buffering. The auxiliary filter assembly 33 is installed on the feed tank 31 and is located inside the solid chamber 311; The second installation assembly 333 on the top, and the second slow flow plate assembly 334 arranged at the lower end of the second installation assembly 333; the second installation assembly 333 uses two installation rods, and the second slow flow plate assembly 334 adopts a conical structure for buffering block, and the second slow flow plate assembly 334 is located at the discharge port of the feed tank 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com