A kind of anti-oxidation pvc communication pipe and preparation method thereof

An anti-oxidation and communication tube technology, applied in the field of communication tubes, can solve the problems of deterioration of physical and mechanical properties, loss of application value, etc., and achieve the effects of good compatibility, improved oxidation resistance, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

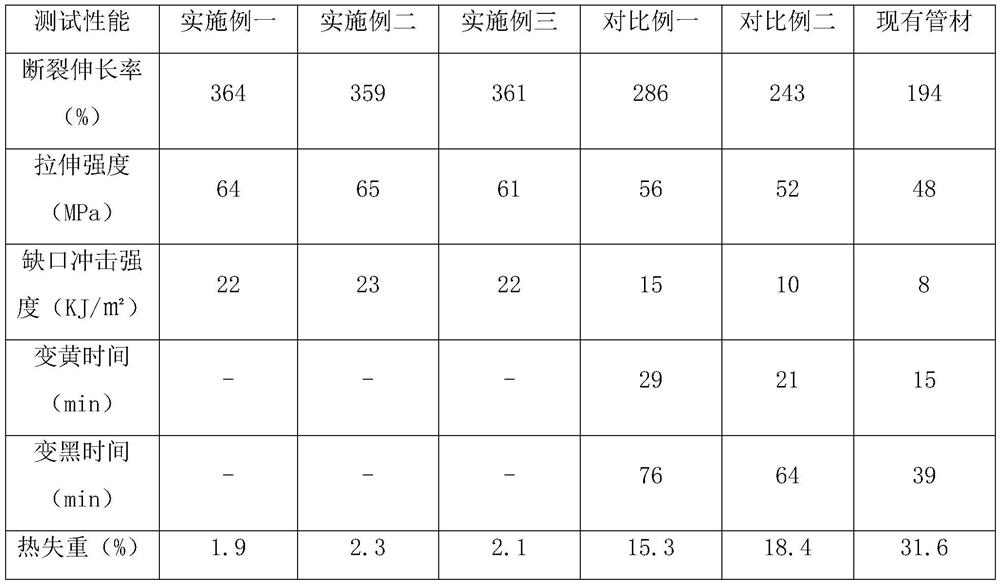

Examples

Embodiment 1

[0029] Preparation of Antioxidant Microcapsules

[0030] Add 10 g of caffeic acid to 500 ml of deionized water, heat to 55 °C and stir to fully dissolve to obtain a caffeic acid solution. Under a nitrogen atmosphere, add ferrous chloride solution with an equal volume concentration of 10 g / L, stir and mix evenly, and then keep the reaction for 2 hours. Then add 8g of polyvinyl alcohol, continue to stir at a speed of 400r / min for 1h, and then perform ultrasonic treatment for 10min to obtain an emulsion. During the whole process of the reaction, adjust the pH to 7-8 with 1mol / L sodium hydroxide solution.

[0031]After stirring and mixing 60g isophorone diisocyanate, 5g 2-hexene-1,6-diol, and 70g cyclohexane evenly, the prepolymerization was carried out under the condition of 50℃ for 2h to obtain a prepolymer. The prepolymer was added dropwise to the emulsion under the condition of stirring at the speed of After the addition was completed, the reaction was continuously stirred fo...

Embodiment 2

[0042] Preparation of Antioxidant Microcapsules

[0043] Add 6g of caffeic acid to 300ml of deionized water, heat to 60°C and stir to fully dissolve to obtain a caffeic acid solution. Under a nitrogen atmosphere, add ferrous chloride solution with an equal volume concentration of 8g / L, stir and mix evenly, and then keep the reaction for 1h. Then add 4g of polyvinyl alcohol, continue to stir at a speed of 400r / min for 2h, and then perform ultrasonic treatment for 10min to obtain an emulsion. During the whole process of the reaction, adjust the pH to 7-8 with 1mol / L sodium hydroxide solution.

[0044] After stirring and mixing 24g isophorone diisocyanate, 3g 2-hexene-1,6-diol and 30g cyclohexane uniformly, the prepolymerization was carried out at 45°C for 1h to obtain a prepolymer. The prepolymer was added dropwise to the emulsion under the condition of stirring at the speed of After the addition was completed, the reaction was continuously stirred for 1 h, naturally cooled to ...

Embodiment 3

[0052] The preparation of antioxidant microcapsules, the preparation of modified titanium dioxide, and the preparation of antioxidant additives are the same as those in Example 1.

[0053] Preparation of PVC Communication Pipe

[0054] First, weigh them according to the following proportions: 115 parts of PVC, 10 parts of CPVC, 10 parts of plasticizer, 5 parts of antioxidant additives, 4 parts of stabilizer, 0.8 parts of external lubricant, 0.5 part of internal lubricant, and processing aid ACR4012 parts, ultraviolet absorber UV-3270.6 parts.

[0055] S1: Put PVC and CPVC in a high-speed mixer, heat up to 90°C, stir and mix for 5 minutes, add plasticizer SG-50, antioxidant additive, and stabilizer calcium stearate, stir and mix for 10 minutes, and add external lubricant Higher fatty acid, inner lubricant higher fatty alcohol, processing aid ACR401, ultraviolet absorber UV-327, stirred and heated to 130° C., and kept stirring for 15s to obtain mixed material 1.

[0056] S2: T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com