Purification and modification method of petroleum residual oil

A technology of petroleum residue and residue oil, which is applied in the field of purification and modification of petroleum residue, which can solve the problems that petroleum residue is not easy to use, and achieve the effects of low content of quinoline insolubles, reduced ash content, and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

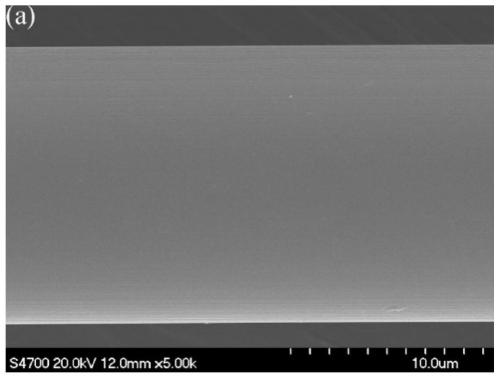

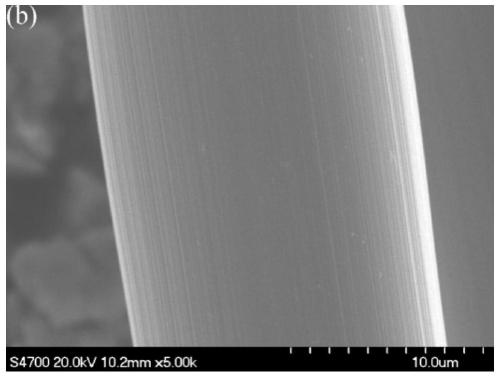

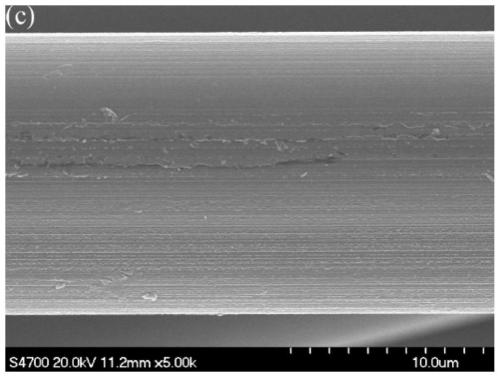

Image

Examples

Embodiment 1

[0037] A method for purifying and modifying petroleum residue, comprising the following steps:

[0038] 1. Preliminary removal of ash in residual oil: Put the residual oil in a heatable horizontal centrifuge at 10,000 rpm, heat it to 50°C, turn on the centrifuge for 10 minutes, and then take out the supernatant for later use.

[0039] 2. Macromolecularize the residual oil and remove the low-activity molecules: put the low-ash residual oil prepared in the first step in a high-pressure reactor, pressurize to 2MPa, react at 400°C for 4 hours, and then cool down to Atmospheric pressure distillation at 300°C for 30 minutes to remove low-activity molecules and small molecules produced by the reaction, leaving high-molecular-weight active heavy residue.

[0040]3. Extraction of solvent-soluble residues such as toluene, quinoline, and n-heptane solubles in heavy residue oil: mix heavy residue oil with 1 times the quality of mixed solvent (toluene: quinoline: n-heptane = 1 :1:1, mass ...

Embodiment 2

[0044] A method for purifying and modifying petroleum residue and a method for preparing mesophase pitch, comprising the following steps:

[0045] 1. Preliminary removal of ash in residual oil: Put the residual oil in a heatable horizontal centrifuge at 10,000 rpm, heat it to 50°C, turn on the centrifuge for 10 minutes, and then take out the supernatant for later use.

[0046] 2. Macromolecularize the residual oil and remove the low-activity molecules: put the low-ash residual oil prepared in the first step in a high-pressure reactor, pressurize to 10MPa, react at 500°C for 10 hours, and then cool down to Atmospheric distillation at 350°C for 60 minutes to remove low-activity molecules and small molecules produced by the reaction, leaving high-molecular-weight active heavy residue.

[0047] 3. Extraction of solvent-soluble residues such as toluene, quinoline, and n-heptane solubles in heavy residue oil: Mix heavy residue oil with 5 times the quality of mixed solvent (toluene: ...

Embodiment 3

[0051] A method for purifying and modifying petroleum residue and a method for preparing mesophase pitch, comprising the following steps:

[0052] The reaction conditions of this embodiment are all the same as in Example 1 except for the following differences.

[0053] Step 3, mix the heavy residue with 2 times the mass of mixed solvent (toluene: quinoline: n-heptane=1:2:2, mass ratio).

[0054] Step 4, put the solvent-soluble residue in the reaction kettle, add tetralin, put it into the reaction kettle at a rate of 0.2kg of tetralin per kilogram of solvent-soluble residue, and put it into the reaction kettle at a temperature of 450°C and a pressure of 2.00MPa React for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com