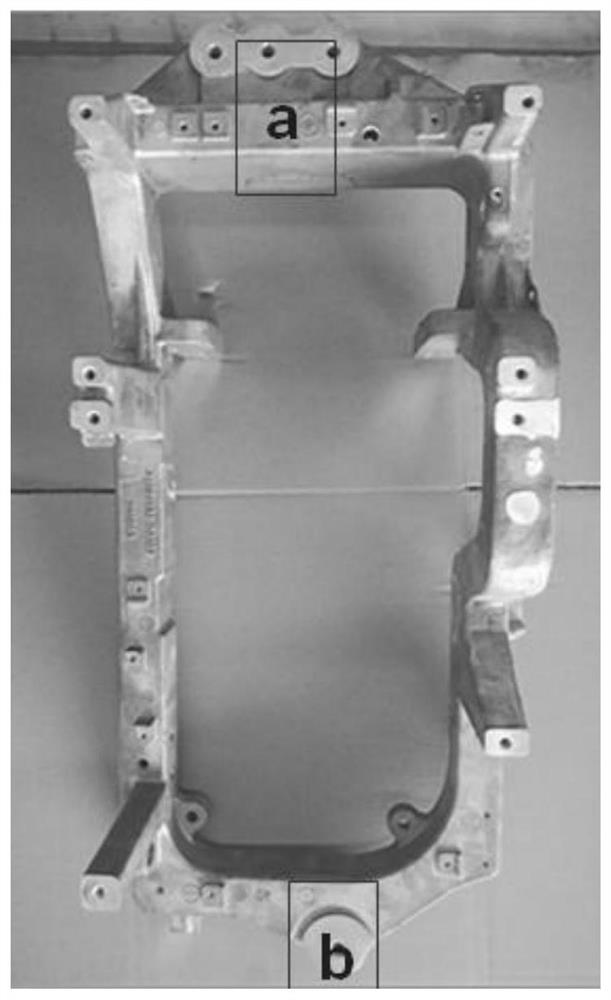

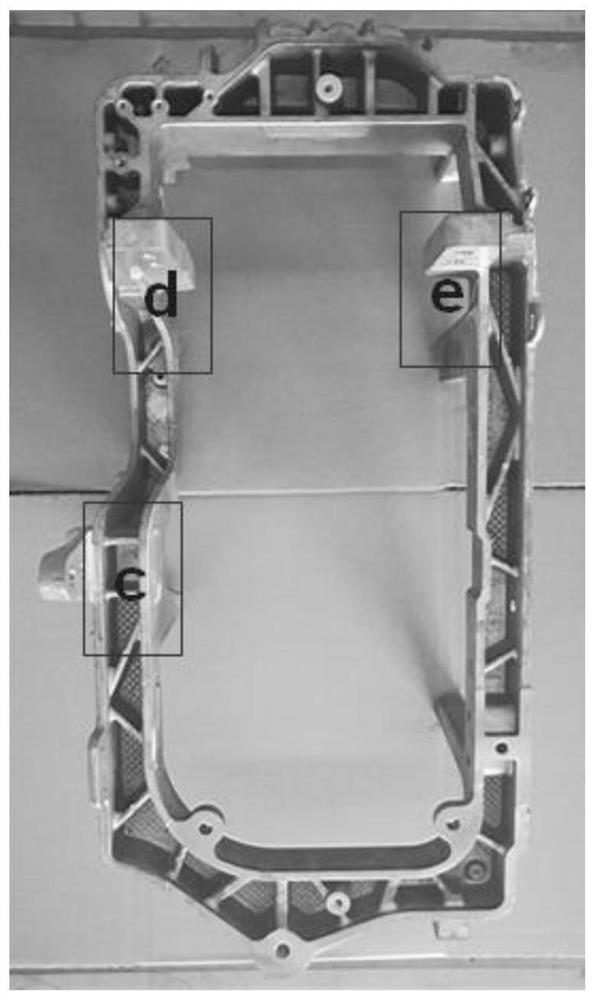

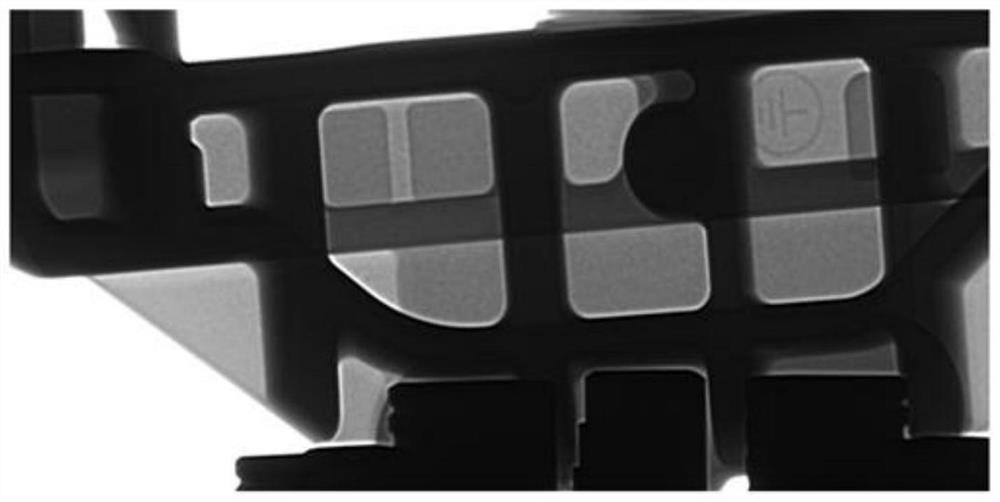

An aluminum alloy integrated electric drive assembly mounting frame and its low-pressure casting method

A mounting frame and low-pressure casting technology, which is applied in the field of aluminum alloy casting, can solve problems such as the inability to meet the preparation requirements of the mounting frame of the integrated electric drive assembly, insufficient mechanical performance indicators, and the total weight of parts, and achieve small dimensional tolerances and surface The effect of small roughness and improved tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention provides an aluminum alloy integrated electric drive assembly mounting frame, the aluminum alloy material used includes the following components by weight percentage: Si: 8.4%, Cu: 1.4%, Mg: 0.65%, Mn: 0.55%, Ti: 0.20%, Fe≤0.2%, Zn≤0.15%, and the rest is Al.

[0036] The low-pressure casting method of the above aluminum alloy material is:

[0037]A. Smelting, refining and refinement of aluminum alloy materials: Put the raw materials into the gas melting furnace according to the above-mentioned composition ratio, heat and melt, and when the temperature of the aluminum alloy liquid rises to 760°C, transfer it to the preheated transfer ladle After adjusting the alloy liquid temperature to 720°C, add AlSr10 modifier and AlTi5B1 refiner, and pass in argon gas for refining and degassing treatment. The refining and degassing treatment time is 9min, and the gas flow rate is 19LPM. After refining, the slag is removed. The aluminum alloy solution is left to stand a...

Embodiment 2

[0043] The invention provides an aluminum alloy integrated electric drive assembly mounting frame, the aluminum alloy material used includes the following components by weight percentage: Si: 9.2%, Cu: 1%, Mg: 0.55%, Mn: 0.45%, Ti: 0.18%, Fe≤0.2%, Zn≤0.15%, and the rest is Al.

[0044] The low-pressure casting method of the above aluminum alloy material is:

[0045] A. Smelting, refining and refinement of aluminum alloy materials: Put the raw materials into the gas melting furnace according to the above-mentioned component distribution ratio, heat and melt, and when the temperature of the aluminum alloy liquid rises to 765°C, transfer it to the preheated transfer ladle After adjusting the alloy liquid temperature to 725°C, add AlSr10 modifier and AlTi5B1 refiner, and pass in argon gas for refining and degassing treatment. The refining and degassing treatment time is 10min, and the gas flow rate is 19LPM. After refining, remove slag and take samples Detection of aluminum sampl...

Embodiment 3

[0051] The invention provides an aluminum alloy integrated electric drive assembly mounting frame, the aluminum alloy material used includes the following components by weight percentage: Si: 8.3%, Cu: 0.8%, Mg: 0.35%, Mn: 0.25%, Ti: 0.13%, Fe≤0.2%, Zn≤0.15%, and the rest is Al.

[0052] The low-pressure casting method of the above aluminum alloy material is:

[0053] A. Smelting, refining and refinement of aluminum alloy materials: Put the raw materials into the gas melting furnace according to the above-mentioned component distribution ratio, heat and melt, and when the temperature of the aluminum alloy liquid rises to 770°C, transfer it to the preheated transfer ladle After adjusting the alloy liquid temperature to 730°C, add AlSr10 modifier and AlTi5B1 refiner, and pass in argon gas for refining and degassing treatment. The refining and degassing treatment time is 10min, and the gas flow rate is 20LPM. After refining, remove slag and take samples Detection of aluminum sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com