Working frequency expansion method of resonant cavity hydrophone

A technology for working frequency and hydrophones, applied in instruments, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of not being able to fully satisfy the rapid design and preparation of hydrophones, many design variables, and high design costs, and achieve Effects of high sensitivity, improved design accuracy, and simplified design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

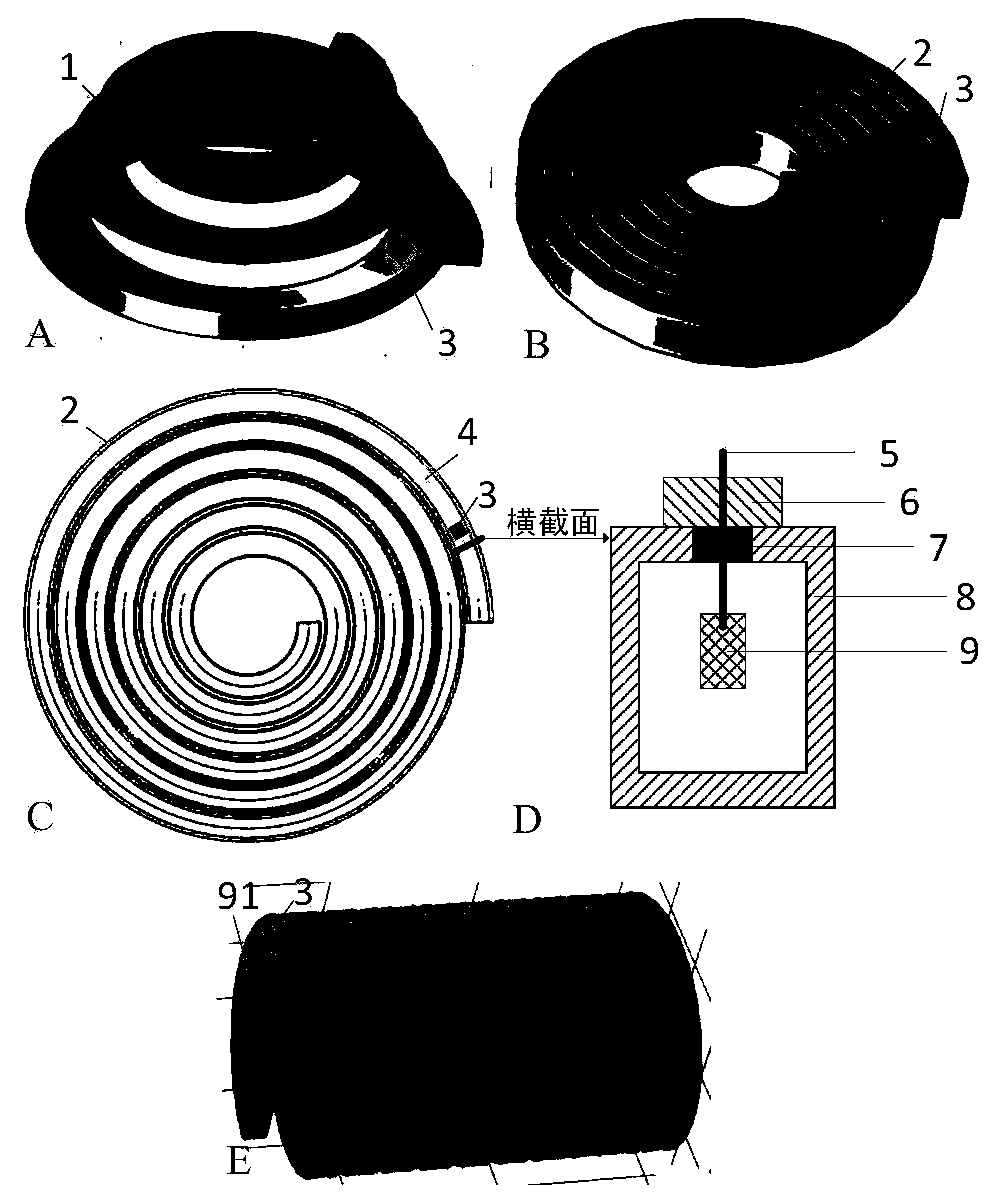

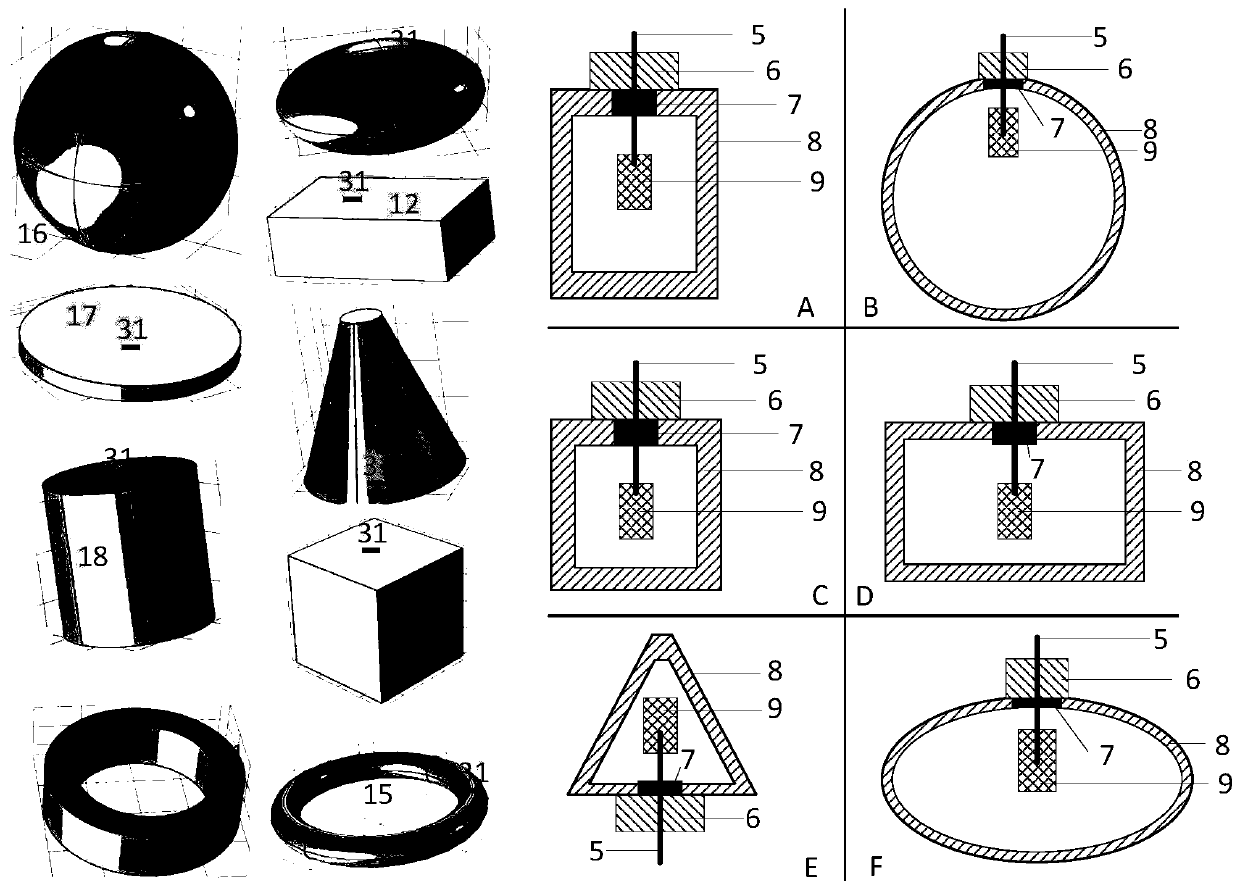

[0028] The hydrophone based on the resonant cavity is composed of an empty shell, which is immersed in water, and a microphone is fixedly arranged inside the empty shell, and the microphone collects sound signals projected from external waters. The shape and size of the shell are determined according to the expected frequency of hydroacoustic detection. The empty shell has no sensitive materials such as piezoelectric ceramics and does not need an impedance matching layer, and can be made by 3D printing, machining, injection molding and other processes. When forming a multi-frequency hydrophone, it can also be composed of a plurality of hydrophones (that is, include a plurality of hollow shells).

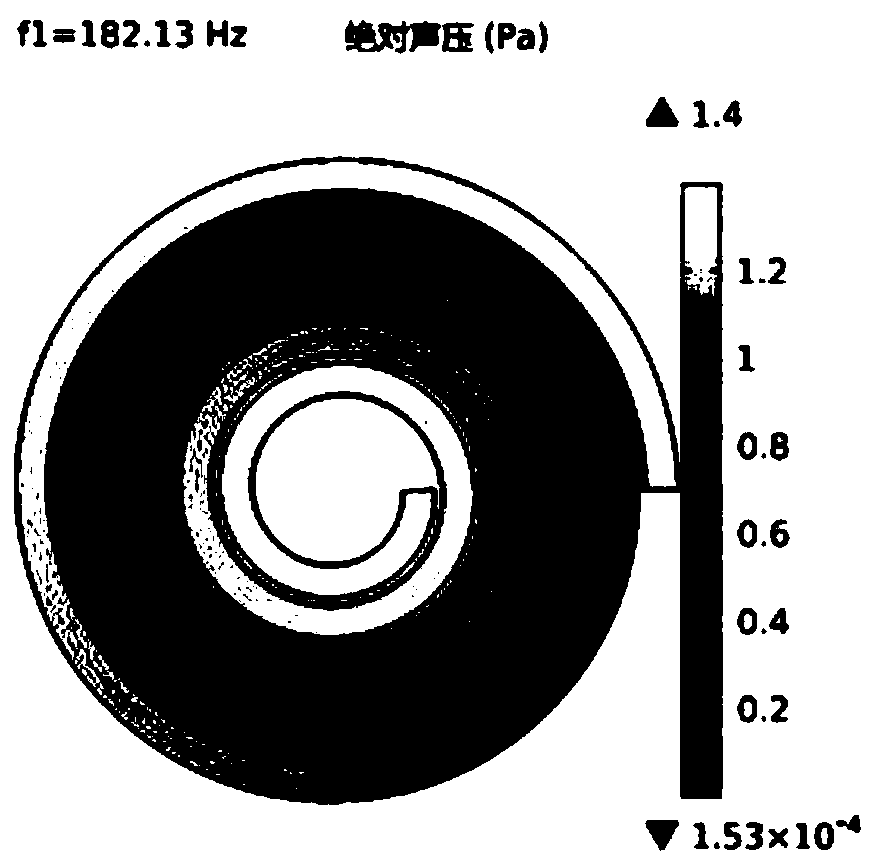

[0029] 1. When the working frequency f0 of the hydrophone is less than or equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com