Temperature measuring method of electromagnetic induction temperature measuring device

A temperature measuring device and electromagnetic induction technology, applied in the field of temperature measurement, can solve problems such as easy to generate errors, test data errors, and oscillating circuits that cannot achieve standard resonance, etc., to achieve the effect of reducing errors and small errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

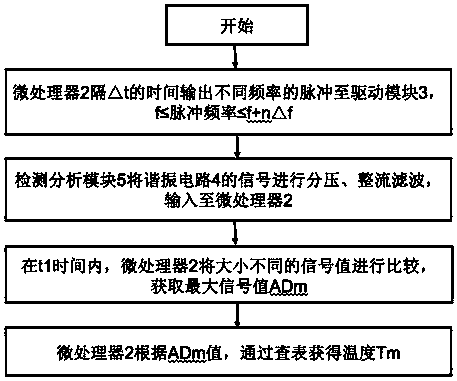

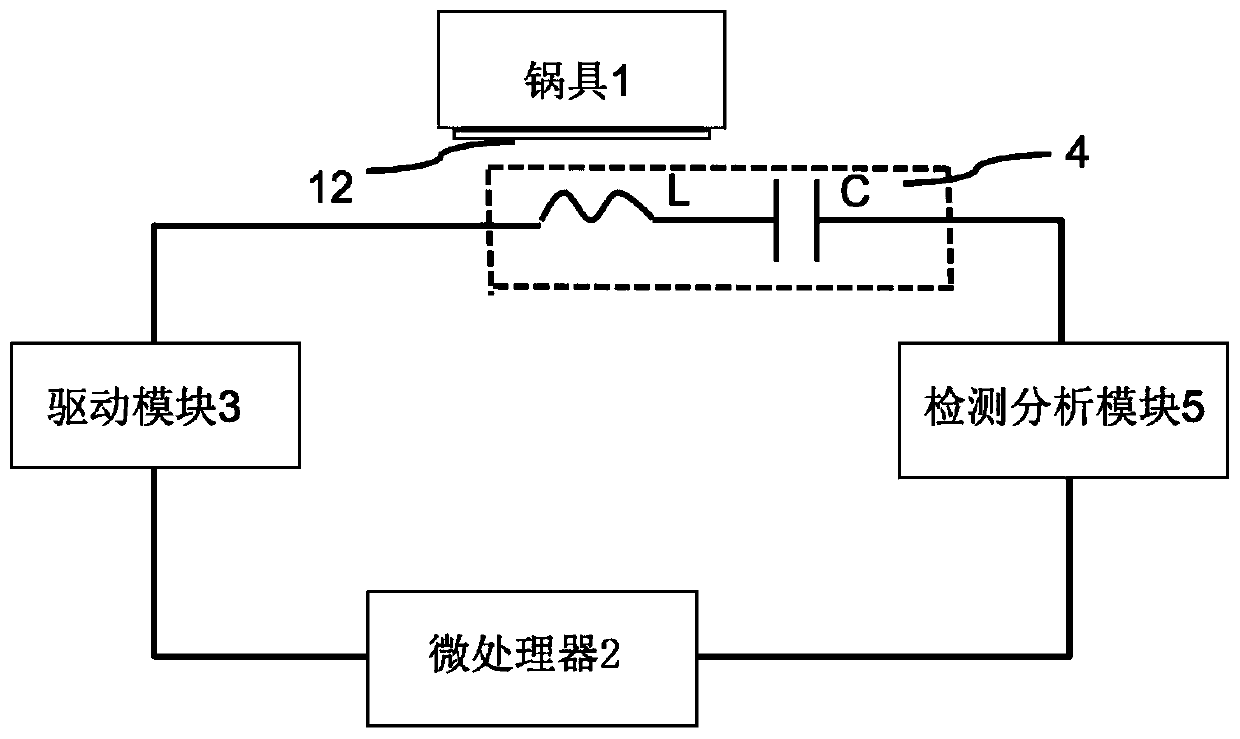

[0044] Such as figure 1 As shown, an electromagnetic induction temperature measuring device provides a pot 1, the pot 1 is provided with a temperature sensing layer 12, and the electromagnetic induction temperature measuring device includes a microprocessor 2, a drive module 3, a resonance Circuit 4 and detection analysis module 5;

[0045] The microprocessor 2 is used to output the pulse driving signal and the signal of the analysis and processing detection analysis module 5, and the microprocessor 2 has an AD port;

[0046] The driving module 3 is used to amplify the pulse signal output by the microprocessor 2 to drive the pulse signal;

[0047] The resonant circuit 4 is used to convert the electrical signal into a magnetic field, including an inductance and a capacitor, both of which are at least one, and the resonant circuit 4 and the temperature-sensing layer 12 generate a coupling impedance;

[0048] The detection and analysis module 5 is used to detect the electrical si...

Embodiment 2

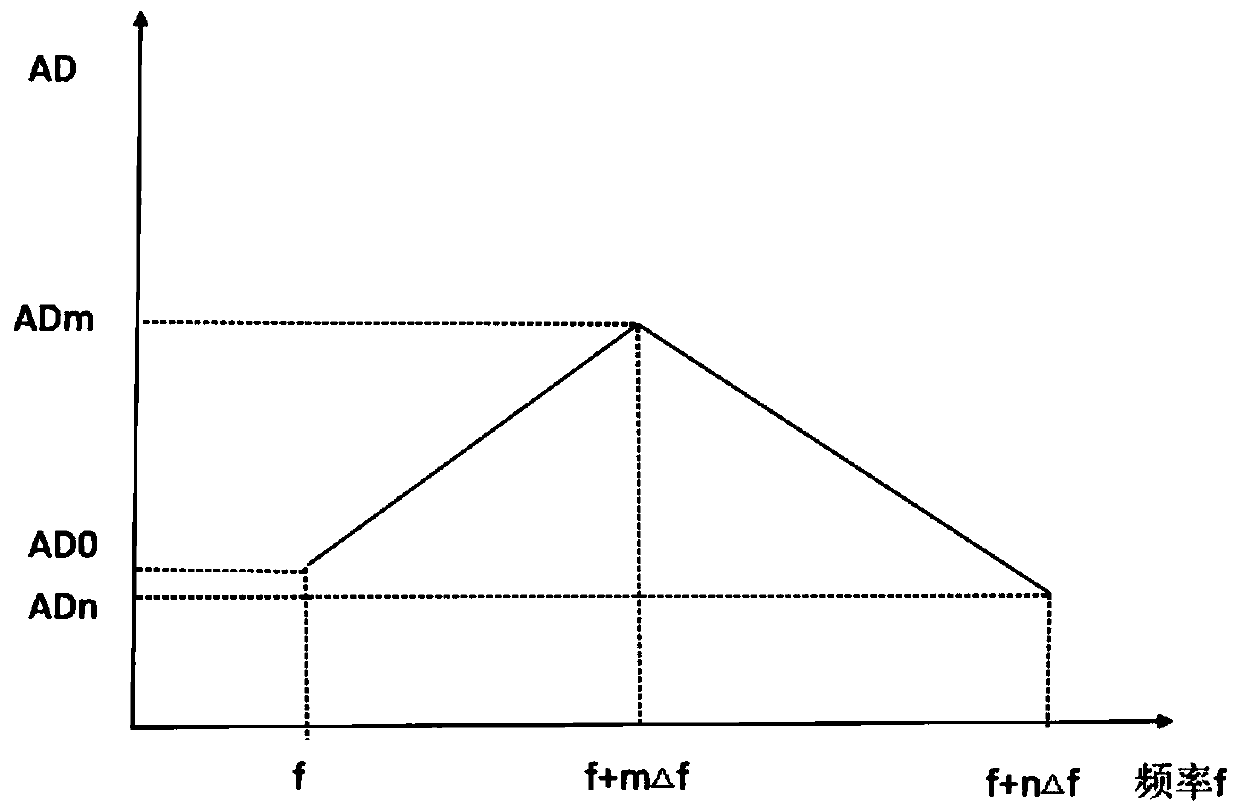

[0065] The difference from Embodiment 1 is that the initial frequency of the pulse is f+n△f, the signal value is ADn, and the frequency of the output pulse of the microprocessor 2 is gradually reduced, gradually reducing △f each time, when the frequency of the pulse is f , the signal value is AD0. image 3 It is a linear relationship diagram between the pulse frequency and the signal value, and the relationship between the pulse frequency and the signal value can also be a curve.

Embodiment 3

[0067] The difference from Embodiment 1 is that 0.01KHz≤Δf≤0.5kHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com