Continuous polarization method for organic piezoelectric film

A piezoelectric thin film, organic technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of long time, difficult processing, difficult to achieve continuous polarization, etc. High efficiency and simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

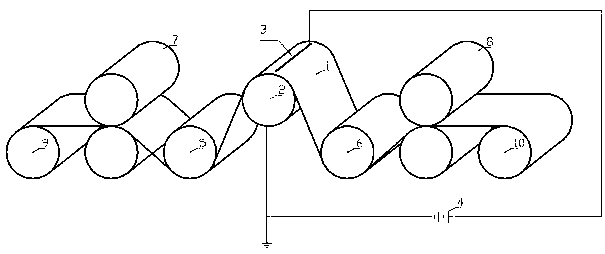

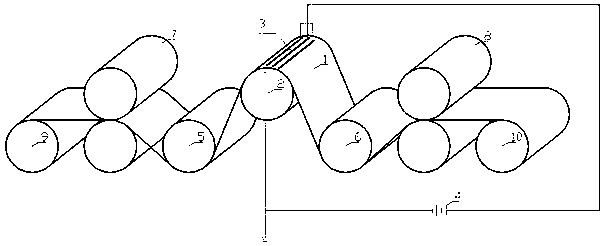

[0028] like figure 1 As shown, the polyvinylidene fluoride piezoelectric film 1 polarization device includes a traction device, a corona electrode 3 and a high-voltage polarization power supply 4 .

[0029] The traction device includes, from front to back, an unwinding roller 9, a front pinch roller group 7, a front guide roller 5, a zero electrode roller 2, a rear guide roller 6, a rear pinch roller group 8 and a traction roller 10. Front pinch roller group 7 and rear pinch roller group 8 all are made of two pinch rollers up and down.

[0030] The corona electrode 3 is made of a single copper wire with an outer diameter of 0.3 mm and is located 10 mm directly above the zero electrode roller 2. The two are respectively connected to the output terminal and the ground terminal of the high-voltage polarization power supply 4 through wires.

[0031] The polyvinylidene fluoride piezoelectric film 1 is prepared by a conventional method: a polyvinylidene fluoride piezoelectric film ...

Embodiment 2

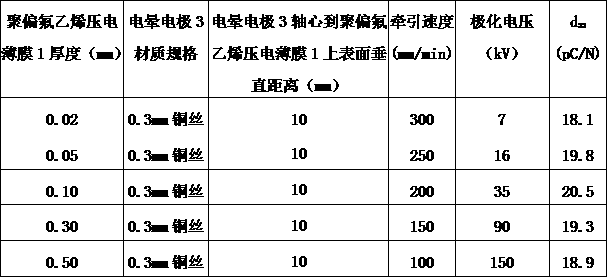

[0037] According to the method of Embodiment 1, the polyvinylidene fluoride piezoelectric film 1 with different thicknesses is polarized at room temperature, and the polarization voltage and pulling speed are adjusted accordingly according to the thickness of the film.

[0038] After the polarization is completed, the measured piezoelectric coefficient of the polyvinylidene fluoride piezoelectric film 1 is shown in Table 1.

[0039] Table 1 Polarization experiments and results of polyvinylidene fluoride piezoelectric film 1 with different thicknesses

[0040]

Embodiment 3

[0042] According to the method of Embodiment 1, the material and diameter of the metal wire of the corona electrode 3 were changed, and the polyvinylidene fluoride piezoelectric film 1 with a thickness of 0.1 mm was polarized at room temperature.

[0043] After the polarization is completed, the measured piezoelectric coefficient of the polyvinylidene fluoride piezoelectric film 1 is shown in Table 2.

[0044] Table 2 Polarization experiments and results of different corona electrodes 3 on 0.1 mm thick polyvinylidene fluoride piezoelectric film 1 at room temperature

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com