Linear type ultrasonic micromotor

An ultrasonic and micro-motor technology, applied in the direction of generators/motors, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motors, etc., can solve the problem of poor performance of miniature linear ultrasonic motors, affecting the performance of piezoelectric ceramics, Low electromechanical coupling coefficient and other problems, to achieve the effect of easy electrode division, large torque and uniform polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

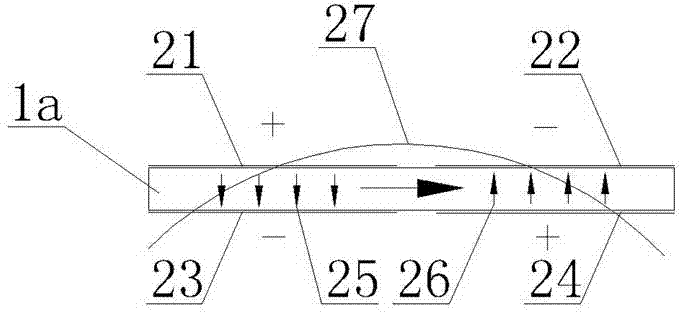

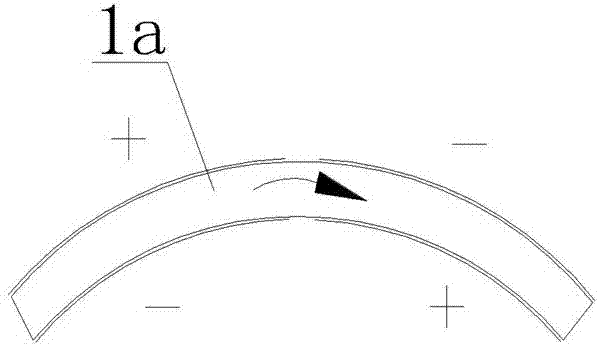

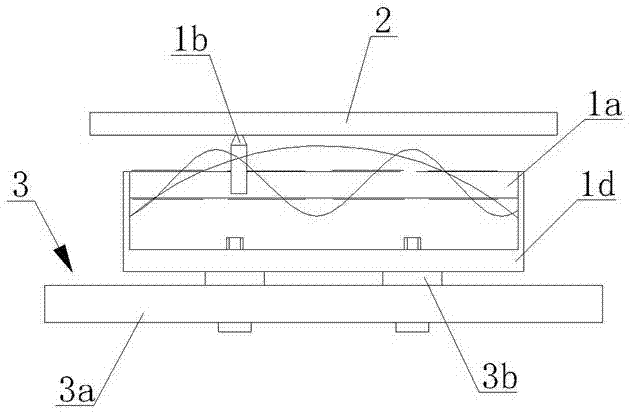

[0043] Example 1: Standing wave type single piezoelectric ceramic plate linear ultrasonic micromotor

[0044] refer to Figure 4 , Figure 5 As shown, the linear ultrasonic micromotor of the present utility model includes a stator 1, a moving part 2 and a fixing mechanism 3. The stator 1 is composed of a thin-plate-shaped piezoelectric ceramic element 1a, a driving foot 1b and a base 1d. The base 1c is usually It is metal, such as copper; the fixing mechanism 3 is composed of a mounting plate 3a and an elastic pad 3b, and the elastic pad 3b is arranged between the mounting plate 3a and the base 1d; the piezoelectric ceramic element 1a is polarized along the length direction; the piezoelectric ceramic element 1a The upper and lower surfaces of the piezoelectric ceramic element 1a are respectively provided with electrodes 4, and the electrodes 4 on the upper and lower surfaces are composed of several small electrode surfaces. The electrode surfaces between the upper and lower s...

Embodiment 2

[0048] Example 2: Standing wave single piezoelectric ceramic plate and matrix composite linear ultrasonic micromotor

[0049] refer to Image 6 As shown, a kind of linear ultrasonic micromotor of the present invention, its structure is basically the same as embodiment 1, the difference is that the electrode 4 on the outer surface of the piezoelectric ceramic plate 1a is made of a plurality of electrode surfaces, and the other side uses On the surface bonded to the substrate 1c is an integral electrode 4, usually grounded. Its incentive mode and working principle are similar to those in Embodiment 1.

Embodiment 3

[0050] Example 3: One of the standing wave double piezoelectric ceramic plate and matrix composite linear ultrasonic micromotor

[0051] refer to Figure 7 As shown, the structure of the linear ultrasonic micromotor of the present invention is basically the same as that of Embodiment 2, the difference is that there are two piezoelectric ceramic elements 1a, which are respectively bonded on the upper and lower surfaces of the substrate 1c, and the two piezoelectric ceramic elements The electrode 4 on the outer surface of the element 1a is composed of multiple electrode surfaces, and the other surface bonded to the substrate 1c is an integral electrode 4, which is usually grounded.

[0052] If two piezoelectric ceramic elements 1a are pasted in the opposite direction of polarization, when excited, an electric field is formed between each electrode surface of the piezoelectric ceramic element 1a and the other symmetrical electrode, and the direction of the electric field in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com