Optical fiber electric embroidery light-emitting sheet

A technology of light-emitting sheet and electric embroidery, applied in electrical components, short-distance communication services, etc., can solve the problems of complex production process and use of fabrics, inability to achieve overall flat lighting, poor quality and reliability, etc., and achieve low production costs and uniform lighting. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0037] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

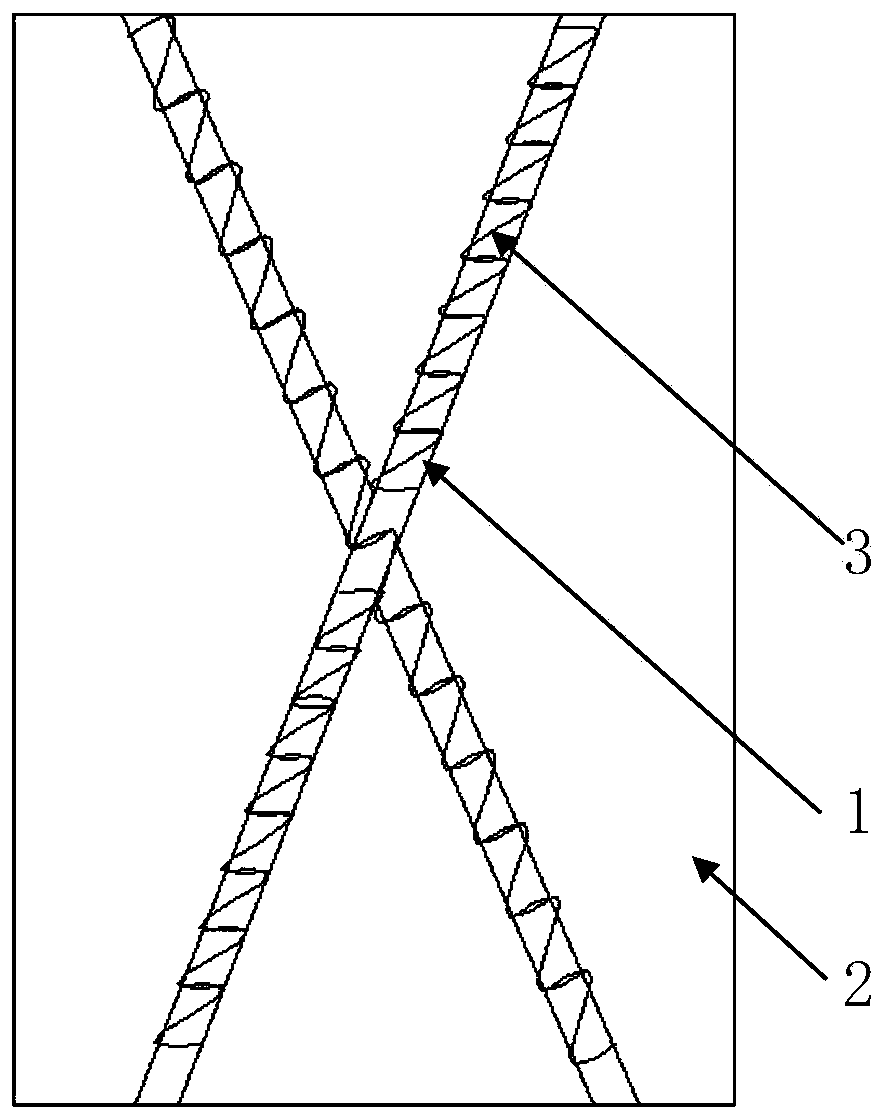

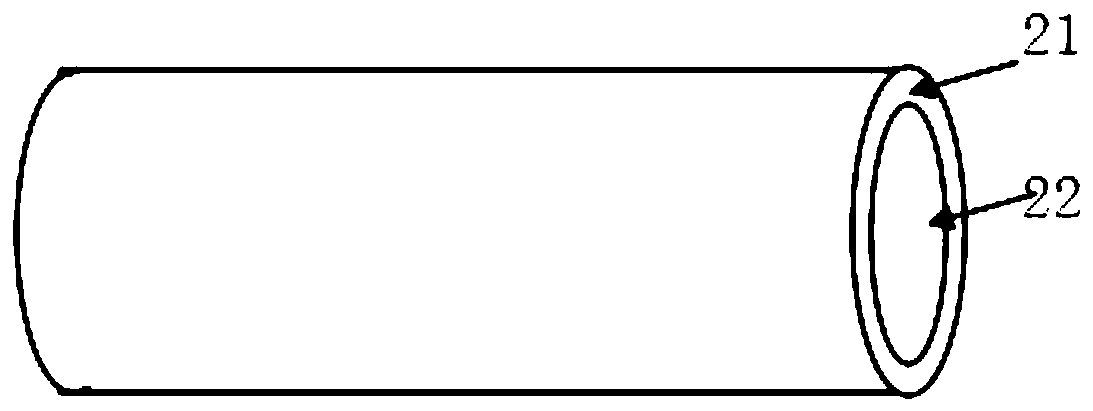

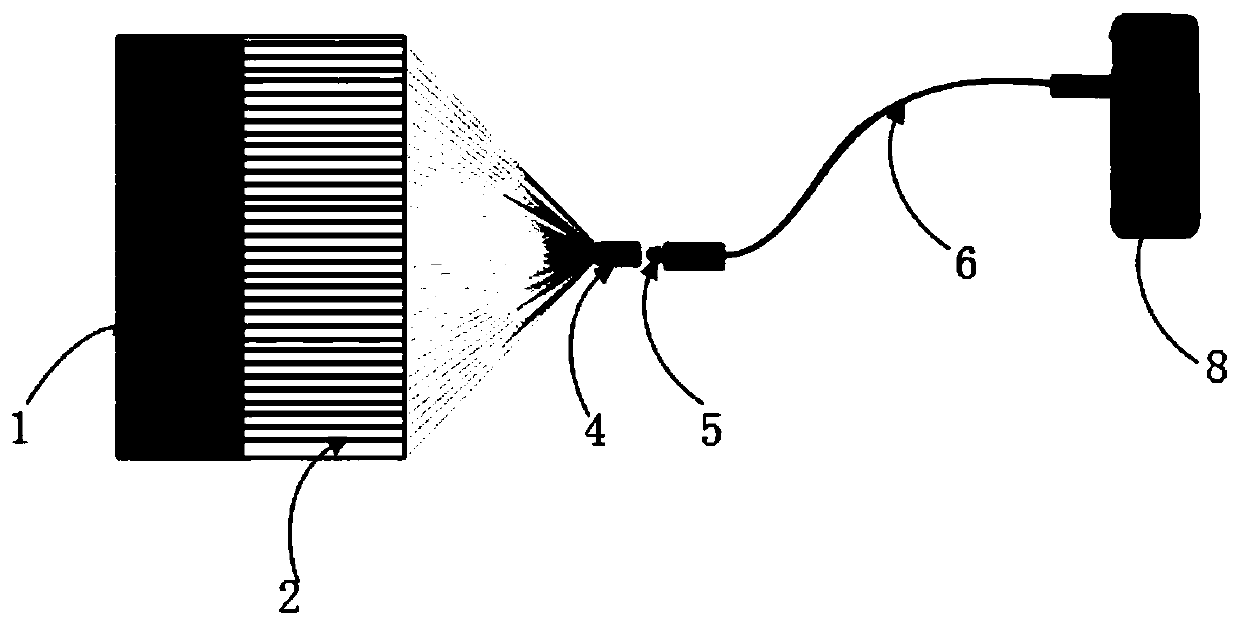

[0038] Such as Figure 1-3 As shown, an optical fiber electric embroidery light-emitting sheet includes a substrate and a light-guiding material thread, and the light-guiding material thread constructs a preset pattern on the surface of the substrate by winding the embroidery thread; the light-guiding material thread 2 The ends of the light sources are connected to the light source ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com