A drying system for paper production and its drying method

A drying method and drying system technology, applied in the field of papermaking, can solve the problems of affecting the drying effect of paper, poor paper impact effect, narrow impact force on the covering surface, etc., so as to improve the drying effect and drying efficiency, improve the impact force, improve the The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

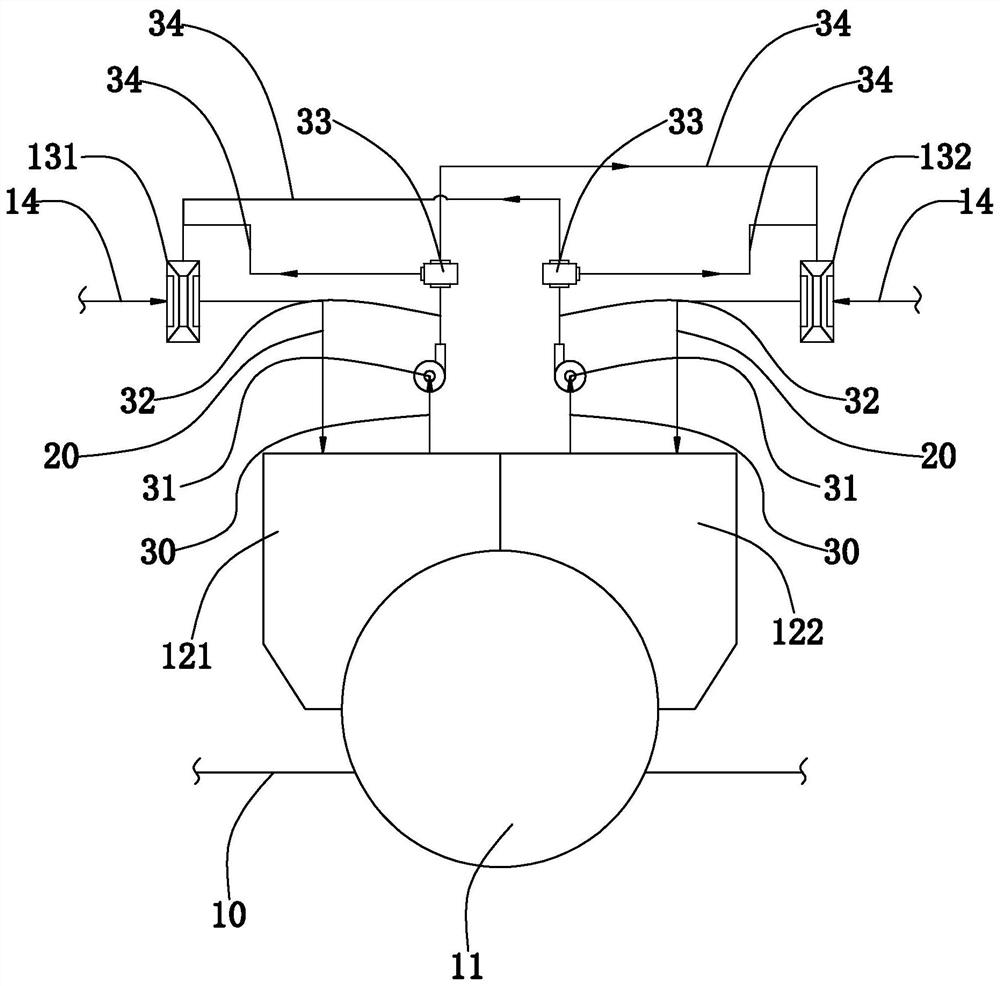

[0041] Such as figure 1 As shown, the present invention discloses a drying system for paper production, which includes a drying cylinder 11 for wet paper sheets 10 to pass through, at least two air hoods arranged on the periphery of the drying cylinder 11, and heating devices corresponding to each air hood And the air supply system 20 communicating between each heating device and each gas hood, in a specific embodiment of the present invention, includes a waste heat recovery system for recovering hot air in each gas hood and returning it to the heating device.

[0042]In a specific embodiment of the present invention, there may be two air hoods, which are divided into a first air hood 121 and a second air hood 122 .

[0043] In a specific embodiment of the present invention, there may be two heating devices, which are respectively a first heating device 131 corresponding to the first gas hood 121 and a second heating device 132 corresponding to the second gas hood 122 .

[00...

Embodiment 2

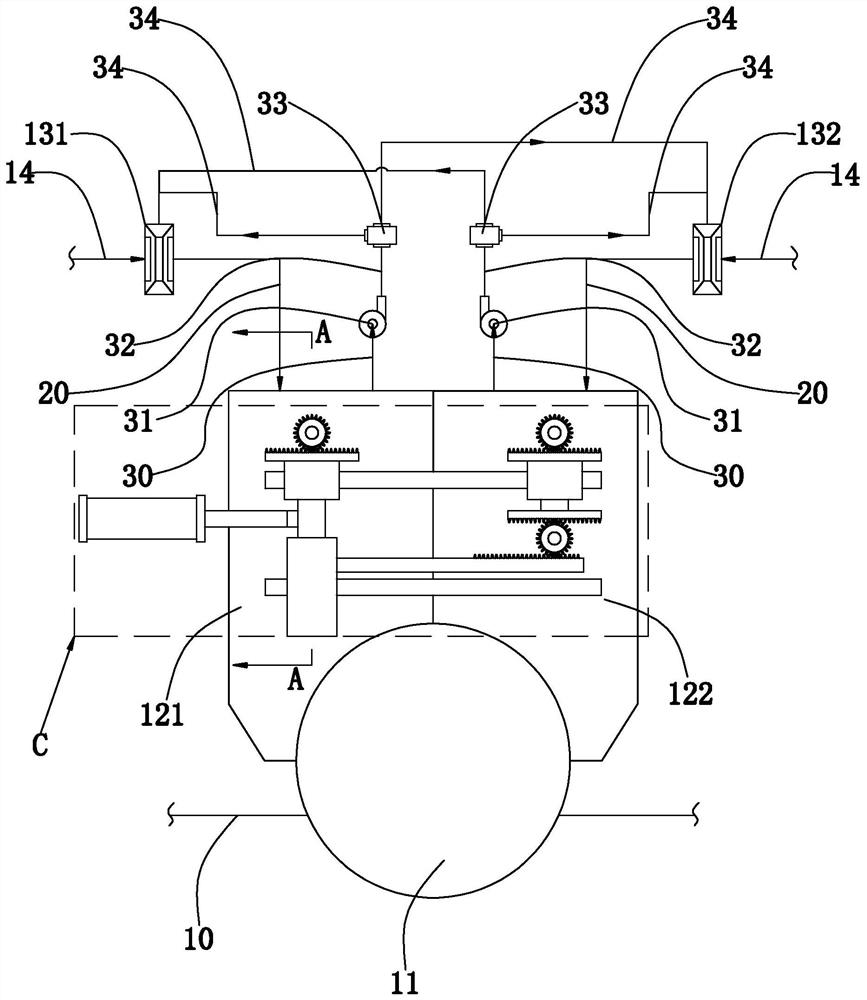

[0051] Embodiment 2, the difference with embodiment 1 is:

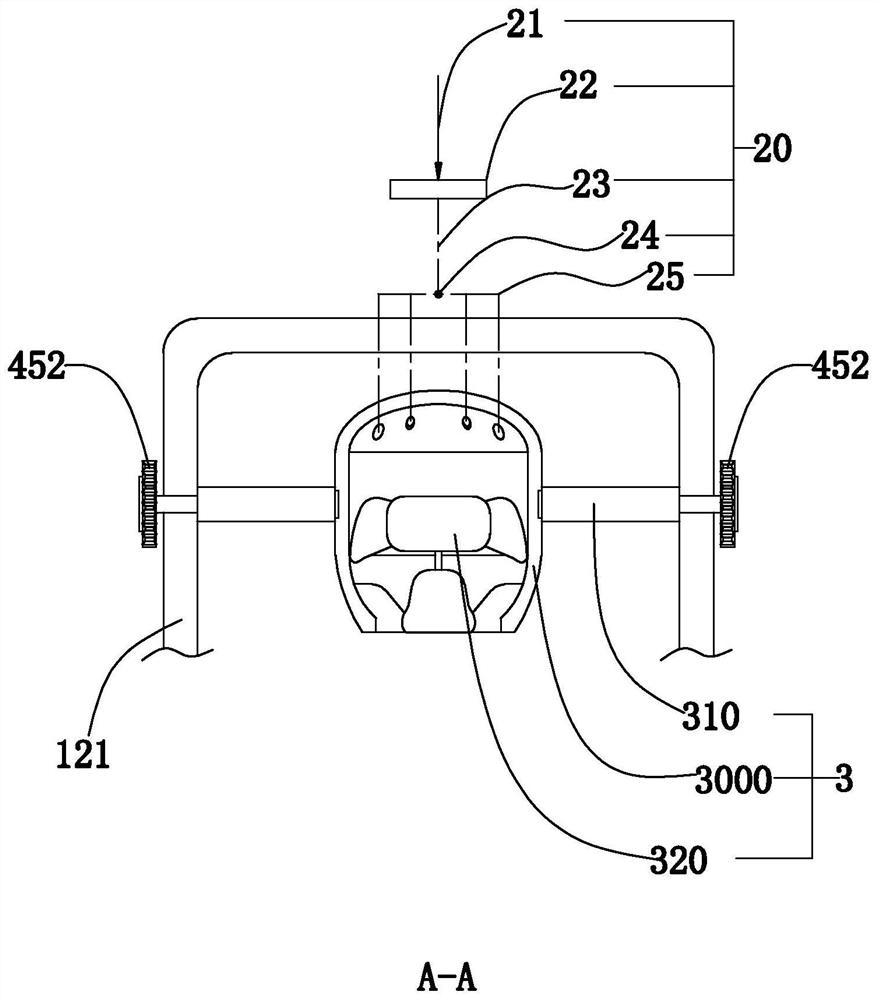

[0052] Such as Figure 2-Figure 7 As shown, in a specific embodiment of the present invention, the air supply system 20 includes a second air source device 22 that communicates with the output end of the heating device through a third air pipe 21 and has an input end and an output end; A fourth air pipe 23 connected to the output end of the air source device 22, a node 24 formed at the output end of the fourth air pipe 23, and several fifth air pipes 25 connected in series with the node 24 for supplying air to the inside of each air hood.

[0053] In a specific embodiment of the present invention, the second air source device 22 may be an air pump.

[0054] In a specific embodiment of the present invention, it also includes an air guide device 3 arranged in each air cover; wherein, the air guide device 3 includes at least one connected to the inner wall of the air cover through a rotating shaft 310 and has the air in...

Embodiment 3

[0068] Embodiment 3, the difference with embodiment 2 is:

[0069] Such as Figure 8 As shown, it also includes a control system for controlling the second air source device 22 and the cylinder 460; wherein, the control system includes a first controller 51 for controlling the cylinder 460, a control system for controlling the second air source device 22 The second controller 52 and the central control unit 53 for sending an execution electrical signal to the first controller 51 or the second controller 52; wherein, the communication interface between the first controller 51 and the second controller 52 Configured as a connection mode; in the connection mode, the first controller 51 operates the cylinder 460 based on the electrical signal sent by the central control unit 53, and at the same time the first controller 51 sends an electrical signal to the second controller 52, and the second The controller 52 operates the second gas source device 22 based on the electric signal....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com