Transient high-temperature field heat flux measuring device and method based on memory alloy

A technology of memory alloy and transient high temperature, which is applied in the field of measurement and detection, can solve the problems of insufficient response speed of contact temperature measurement method, large influence on the emissivity of the measured object of non-contact temperature measurement method, and susceptibility to other factors. Achieve the effect of fast quantitative passive measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to facilitate those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

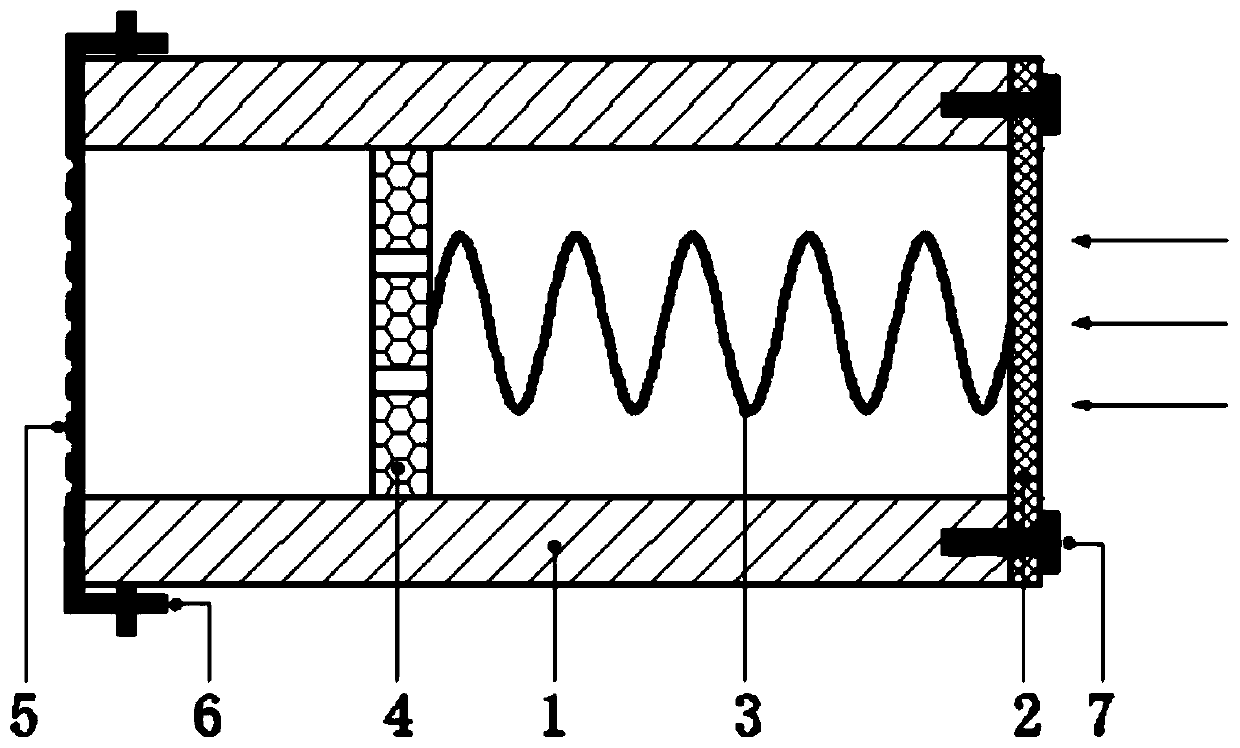

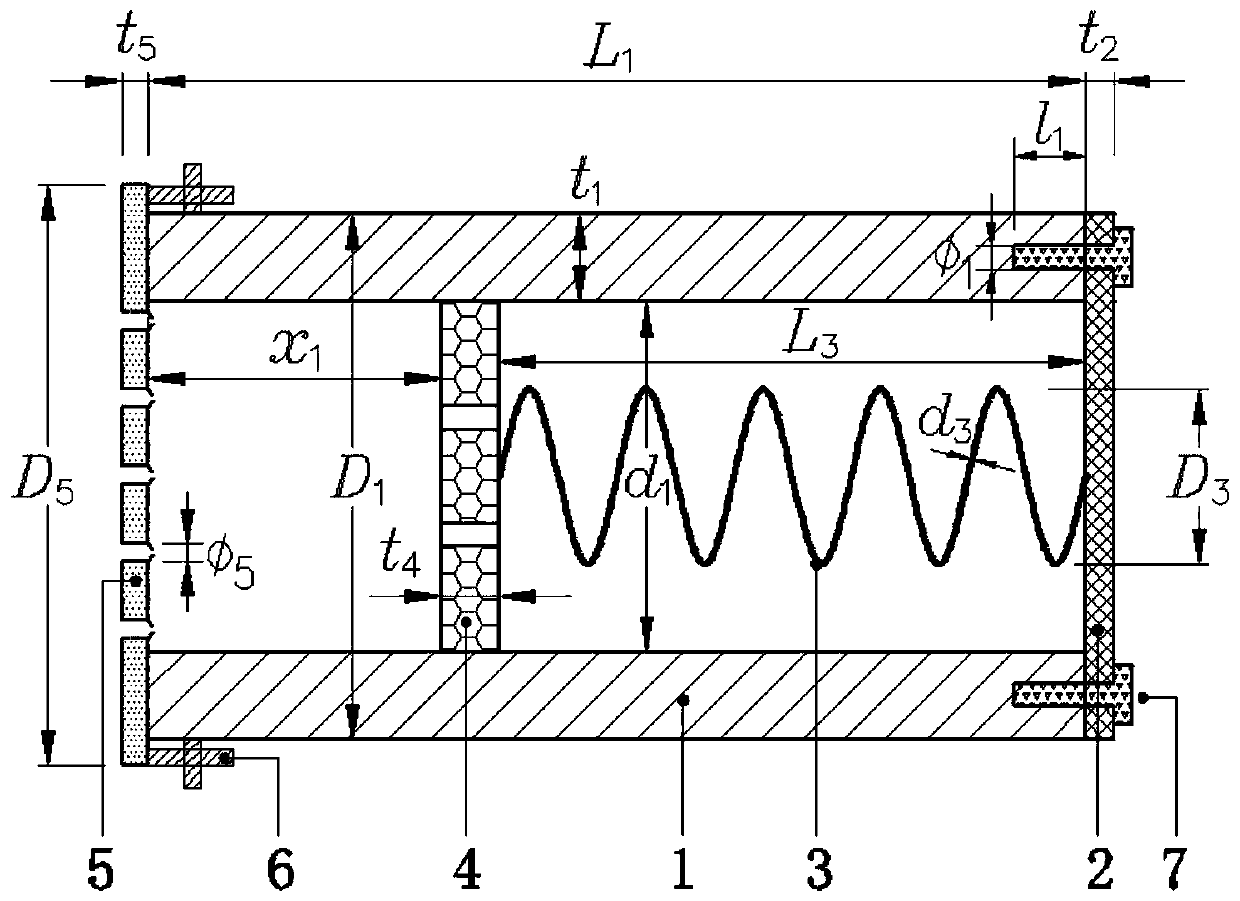

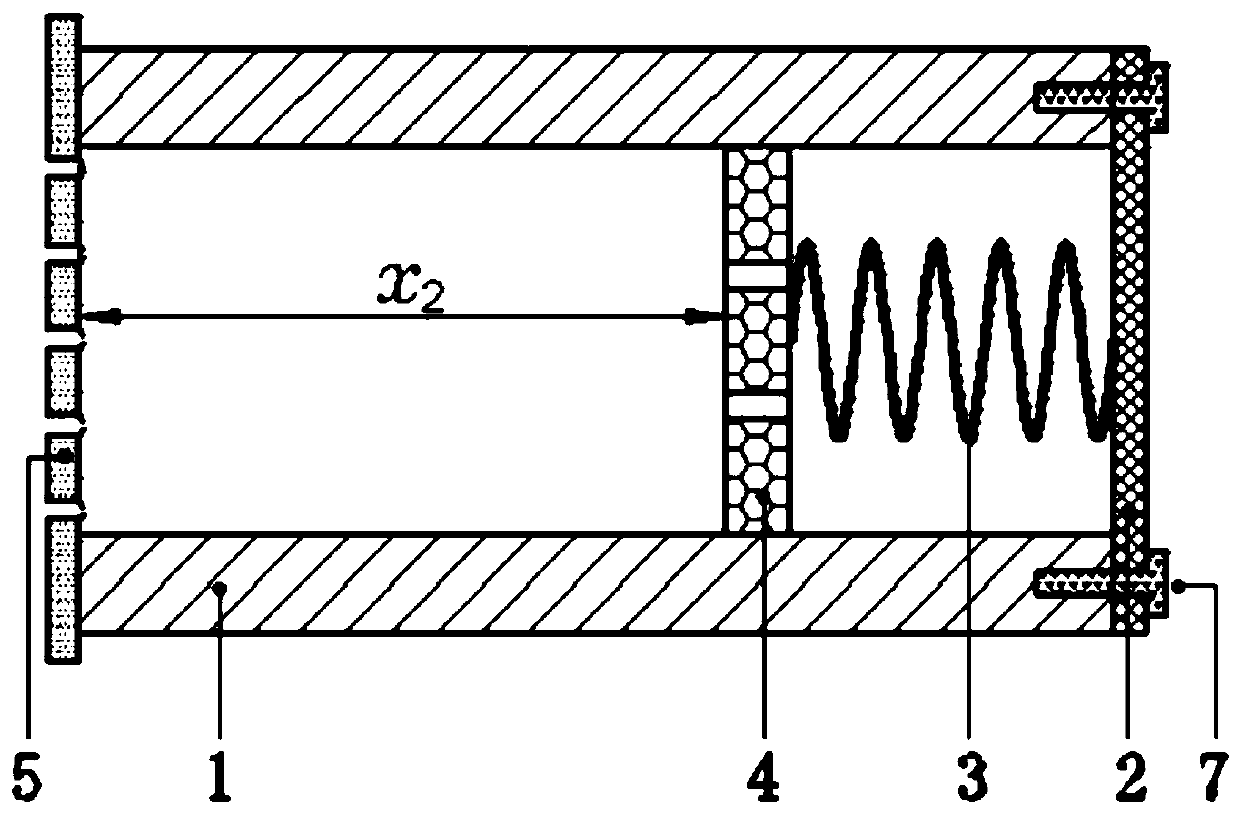

[0049] figure 1 It is a schematic diagram of the overall structure of the transient high-temperature field heat flux measurement device based on the memory alloy of the present invention. Such as figure 1 As shown, the memory alloy-based transient high-temperature field heat flux measuring device of the present invention is composed of a package casing 1, a heat-sensitive element 2, a memory alloy member 3, a slider 4, a fixed base 5, a movable bolt 6, and a screw 7. Define the end of the present invention close to the heat-sensitive element 2 as the right end, and define the end of the present invention far away from the heat-sensitive element 2 as the left end. The memory alloy member 3 and the slider 4 are located in the encapsula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com