Developer composition used in fields of flat panel display and semiconductors

A flat-panel display and semiconductor technology, applied in the field of surfactants, can solve the problems of residual development, slow development speed, excessive foam, etc., and achieve the effects of moderate development speed, increased concentration, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0044] Experimental example: Determination experiment of developing performance of developing solution

[0045] In order to evaluate the developing performance of the CF developer compositions in Examples 1-12 and Comparative Examples 1-6 above, the developing performance test of the developer was carried out by the following test.

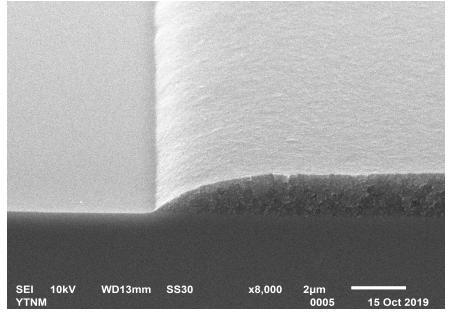

[0046] 1. Manufacturing test pieces

[0047] In order to evaluate the development performance of the developer composition to the photoresist, the test piece used is to spin coat a layer of 1.5 μm BM negative photoresist or R, G, B photoresist on a glass substrate of 5 cm * 5 cm, The specific treatment is as follows: After the glass substrate is thoroughly cleaned with a special cleaning agent, rinsed with ultrapure water, and blown dry with nitrogen. The photoresist was spin-coated with a spin coater at a speed of 300rpm. After vacuuming to remove most of the solvent, it was cured by heating on a flat plate at 100°C. The curing time was 150s. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com