Single-crystal magnetic powder and magnetorheological fluid thereof, and method

A technology of magnetorheological fluid and magnetic powder, which is applied in the field of preparing magnetorheological fluid containing single crystal magnetic powder, single crystal magnetic powder and magnetorheological fluid prepared therefrom, which can solve the lack of performance consistency and product performance degradation time and other problems, to achieve excellent thermal stability, crisp and fast response, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

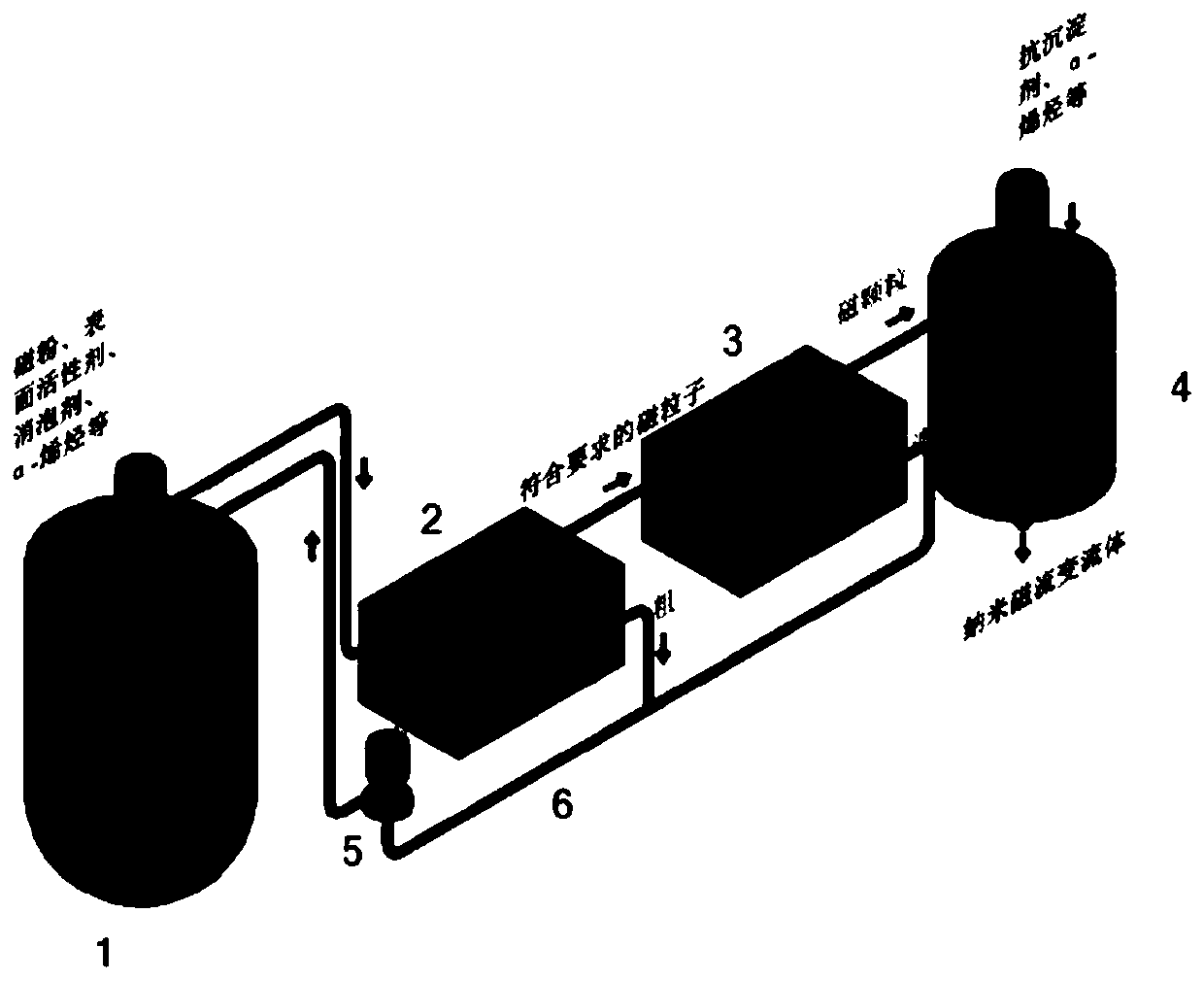

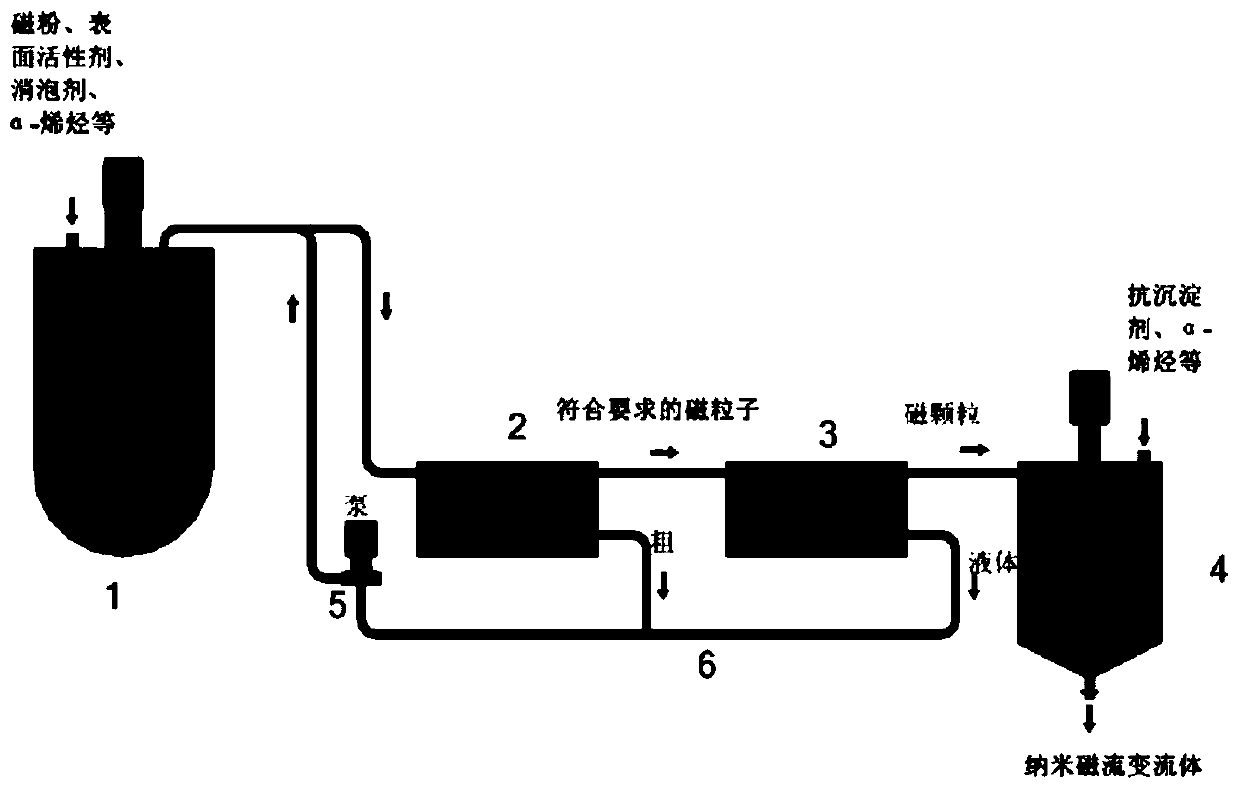

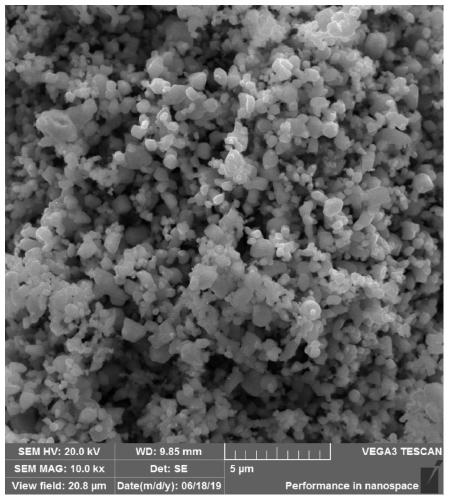

[0091] image 3 It is a scanning electron microscope (SEM) photo enlarged by 10000 times of the single crystal magnetic powder particles prepared according to an embodiment of the present invention, showing the morphology of the single crystal magnetic powder particles under the magnification; Figure 4A It is a scanning electron microscope (SEM) photograph of single crystal magnetic powder particles in another size range according to an embodiment of the present invention enlarged by 10,000 times, showing the morphology of single crystal magnetic powder particles at this magnification; Figure 4B It is a scanning electron microscope (SEM) photograph magnified 10,000 times from commercially available magnetic powder particles of a comparative example for comparison with the present invention. Figure 3-4A The different sizes and morphologies of the single crystal magnetic powder particles prepared according to the present invention are shown. It can be seen that the overall ...

example 1

[0098] According to Example 1, 30 g / l of single crystal magnetic powder is provided, 28.05 g / l of α-olefin as carrier liquid, 1.2 g / l of antiwear agent, 0.3 g / l of dispersant, and 0.45 g / l of antioxidant. Stir the carrier liquid and various additives at a low speed of 300r / min for 10min, add single-crystal magnetic powder, stir at 1200r / min for 20min, and prepare a primary mixed slurry of single-crystal magnetorheological fluid with a magnetic powder ratio of about 72%. .

example 2

[0099] According to example 2, provide 30g / l of single crystal magnetic powder, 28.05g / l of α-olefin as carrier liquid, 1.2g / l of anti-wear agent, 0.3g / l of powder, and 0.45g / l of antioxidant. First, stir the carrier liquid and various additives at a low speed of 300r / min for 10min, add single crystal magnetic powder, stir at 1200r / min for 20min, and configure it as a primary mixed material of single crystal magnetorheological fluid with a magnetic powder ratio of about 50%. pulp.

[0100] Precipitation and separation process

[0101] The slurry through the primary mixing is sent to the sedimentation separator 2, such as a self-made gravity separator or centrifugal separator (such as model LW50*1100), and the particle size meets the requirements (such as about 0.1-8 microns) by gravity or centrifugal force. The particle size range, the particle size range may be different according to the specific type of single crystal magnetic powder, process requirements and application ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com