Three-stage brushless alternating-current synchronous generator and rotary rectifier

A technology of rotating rectifiers and bus bars, applied in synchronous generators, electrical components, electromechanical devices, etc., can solve problems such as uneven centrifugal force, poor heat dissipation, deformation of diode pins, etc., achieve rapid and effective suppression effects, and simplify connections method, the effect of leakage current improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

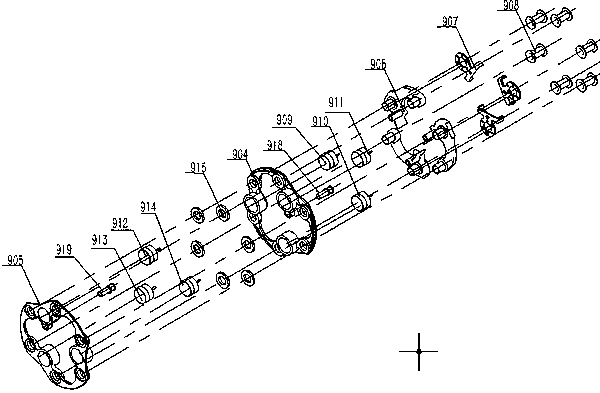

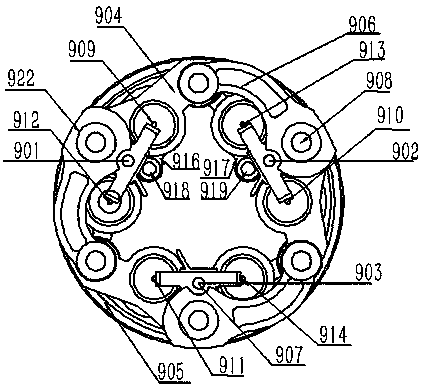

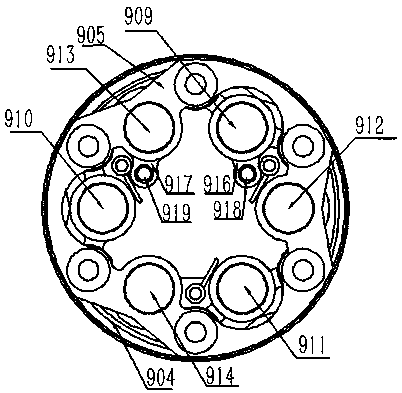

[0051] figure 1 Among them, the rotary rectifier is negative plate 905, negative plate rivet 919, diode ZD4 (912), diode ZD5 (913), diode ZD6 (914), six insulating gaskets 915, positive plate 904, positive plate from left to right Rivet 918, diode ZD1 (909), diode ZD2 (910), diode ZD3 (911), three bus bar brackets 906, three bus bars 907, six hollow rivets 908;

[0052] Further, the diode ZD4 ( 912 ), the diode ZD5 ( 913 ), the diode ZD6 ( 914 ), the diode ZD1 ( 909 ), the diode ZD2 ( 910 ), and the diode ZD3 ( 911 ) are of avalanche type or Zener type.

[0053] figure 2 , image 3 , Figure 4 Among them, when the rotating rectifier is assembled, six hollow rivets 908 fix the positive plate 904, negative plate 905, six insulating gaskets 915, three bus bar brackets 906, and three bus bars 907 into a whole; the outer surface of the hollow rivet 908 A layer of insulating film 922 is provided; diode ZD1 (909), diode ZD2 (910), and diode ZD3 (911) are installed on the positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com