Quick-freezing processing method for legume vegetables

A processing method, technology of legumes and vegetables, applied in the directions of preservation of fruits and vegetables, preservation of fruits/vegetables by heating, preservation of fruits/vegetables by freezing/refrigeration, etc., can solve the problem that polyphenol oxidase and peroxidase cannot be well inhibited , VC loss, beans and vegetables become soft, etc., to shorten the blanching time, reduce the loss of VC, and ensure food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

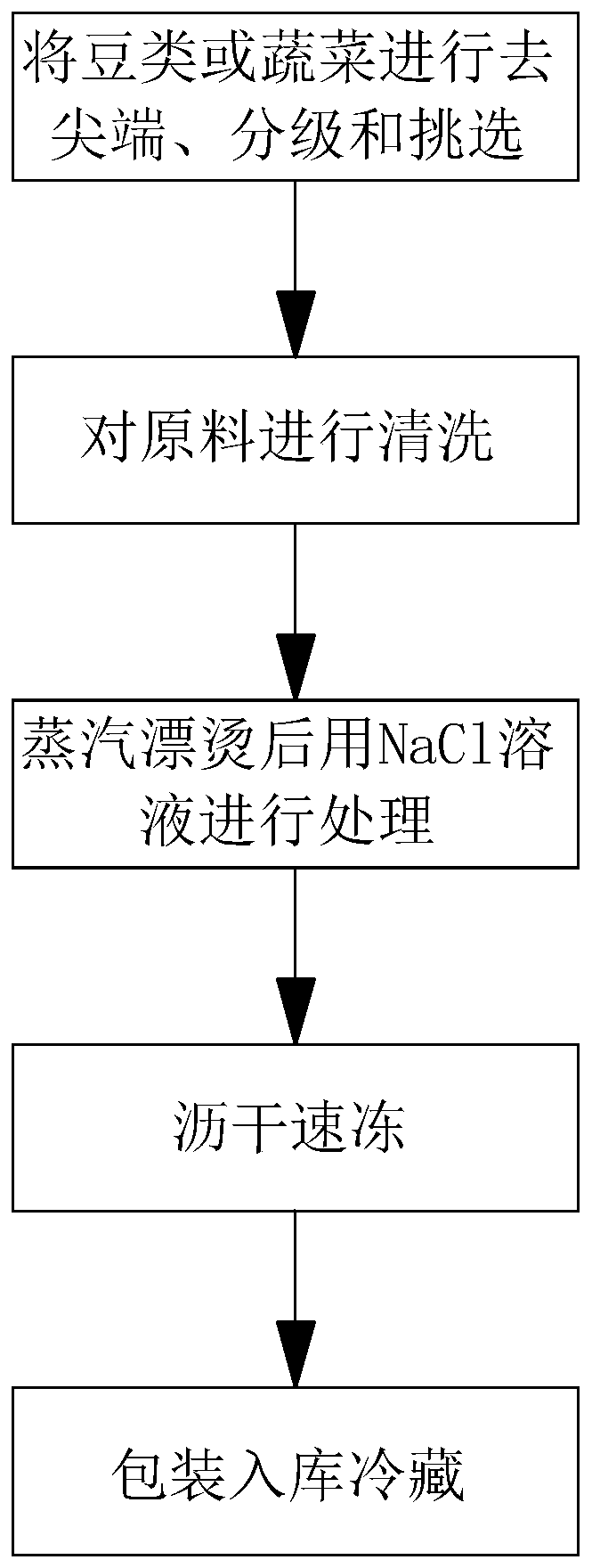

Method used

Image

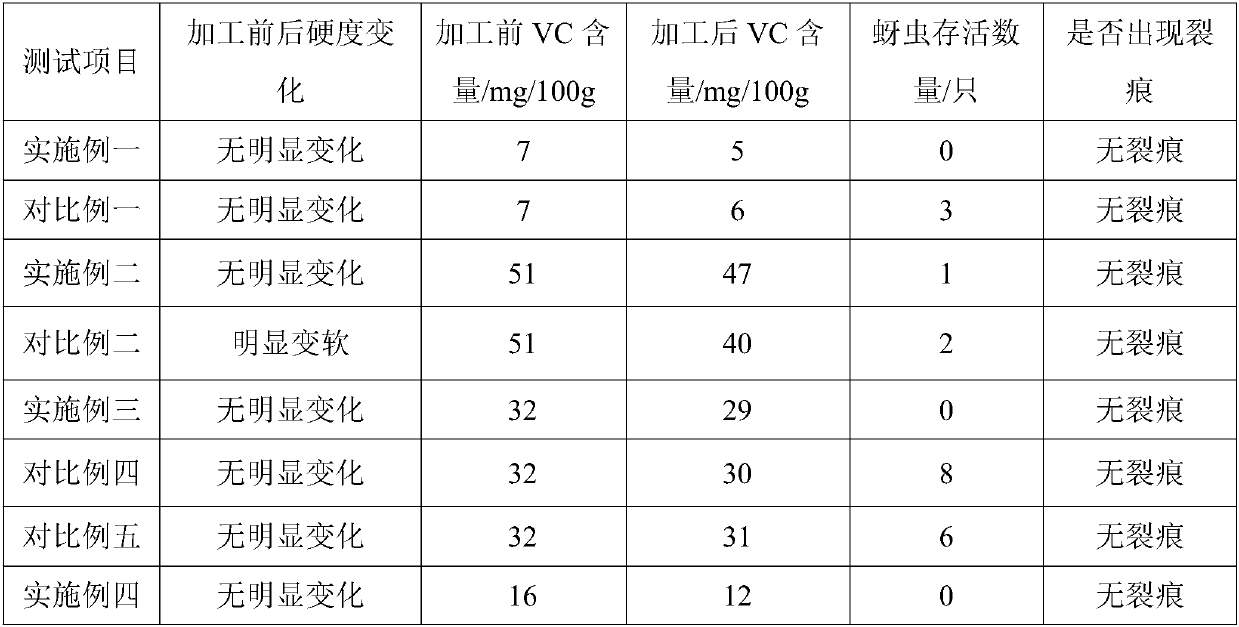

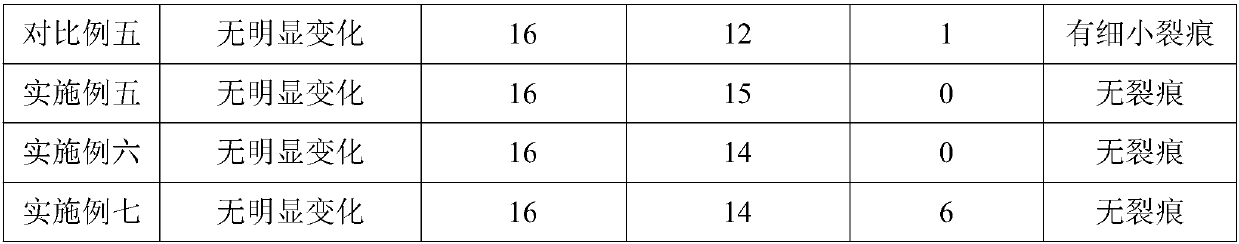

Examples

Embodiment 1

[0038] A quick-freezing processing method for legume vegetables, comprising the steps of:

[0039] Step 1: Peas are de-pointed, graded and selected;

[0040] Step 2: Soak the peas in the cleaning solution for 4 minutes, and then wash them with water;

[0041] Step 3: Use 100°C saturated steam to blanch the peas for 50 seconds, use 40°C warm water to cool the raw materials gradually to 60°C, and keep them for 10 minutes, then use normal temperature water to cool the raw materials to normal temperature, and put the blanched raw materials Treat with 1wt% NaCl solution for 4min;

[0042] Step 4: Drain the raw materials by means of centrifugation, and blow carbon dioxide gas with a temperature of 40°C into the raw materials, and then perform a quick-freezing operation to reduce the temperature of the raw materials to -18°C;

[0043] Step 5: Pack the quick-frozen raw materials, fill the package with nitrogen, and then put it in storage for refrigeration.

[0044] Among them, the ...

Embodiment 2

[0048] A quick-freezing processing method for legume vegetables, comprising the steps of:

[0049] Step 1: De-tipping, grading and selecting the broccoli;

[0050] Step 2: Soak the broccoli in the cleaning solution for 5 minutes, and then wash it with water;

[0051] Step 3: Use 100°C saturated steam to blanch the broccoli for 60 seconds, use 50°C warm water to cool the raw material gradually to 60°C, and keep it for 10 minutes, then use normal temperature water to cool the raw material to normal temperature, and blanched The raw material was treated with 2wt% NaCl solution for 3 minutes;

[0052] Step 4: Drain the raw materials by means of centrifugation, and blow carbon dioxide gas with a temperature of 40°C into the raw materials, and then perform a quick-freezing operation to reduce the temperature of the raw materials to -18°C;

[0053] Step 5: Pack the quick-frozen raw materials, fill the package with nitrogen, and put it in storage for refrigeration.

[0054] Among t...

Embodiment 3

[0058] A quick-freezing processing method for legume vegetables, comprising the steps of:

[0059] Step 1: De-pointing, grading and selecting the spinach;

[0060] Step 2: Soak the spinach in the cleaning solution for 6 minutes, and then wash it with water;

[0061] Step 3: Use 100°C saturated steam to blanch the spinach for 55 seconds, use 45°C warm water to cool the raw material gradually to 60°C, and keep it for 10 minutes, then use normal temperature water to cool the raw material to normal temperature, and put the blanched raw material Treat with 3wt% NaCl solution for 4min;

[0062] Step 4: Drain the raw materials by means of centrifugation, and blow carbon dioxide gas with a temperature of 40°C into the raw materials, and then perform a quick-freezing operation to reduce the temperature of the raw materials to -18°C;

[0063] Step 5: Pack the quick-frozen raw materials, fill the package with nitrogen, and put it in storage for refrigeration.

[0064] Among them, the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com