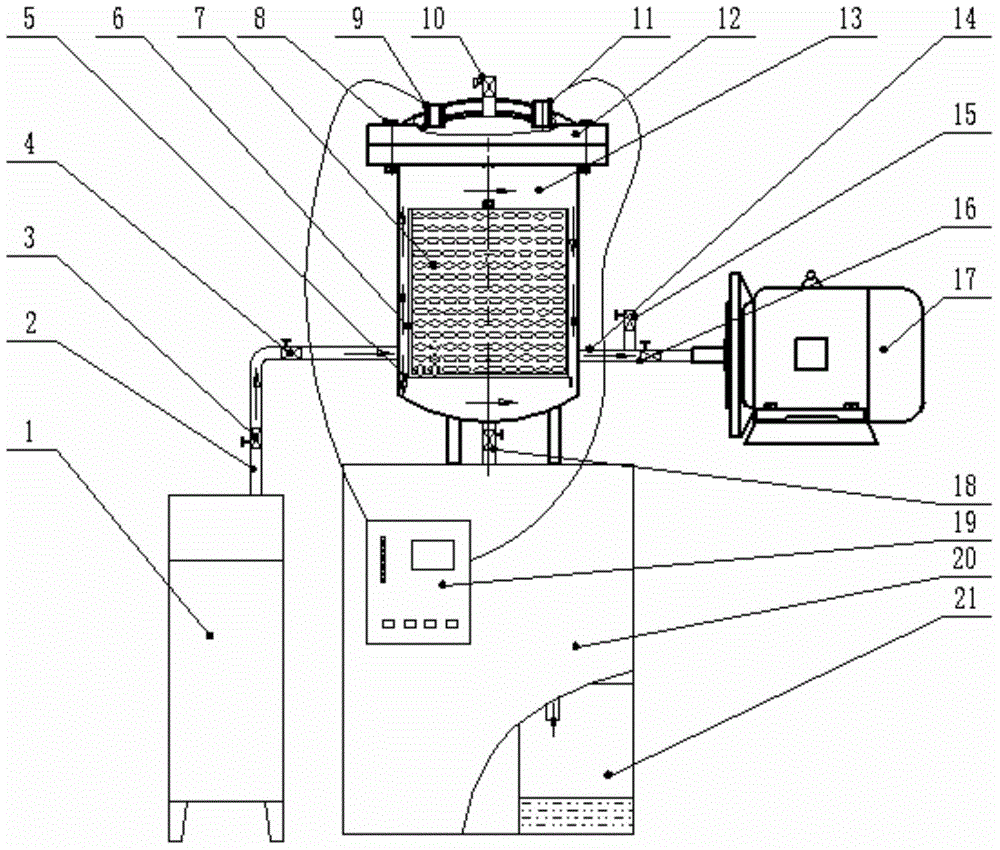

Vacuum-steam pulse blanching equipment and method for blanching employing vacuum-steam pulse blanching equipment

A steam and vacuum technology, applied in application, food processing, heating and preservation of fruits/vegetables, etc., can solve problems such as low heat utilization efficiency, uneven blanching, and impermeability of steam, so as to reduce blanching costs and shorten drying time, the effect of reducing thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Use vacuum-steam pulsating blanching equipment to blanch fresh lilies.

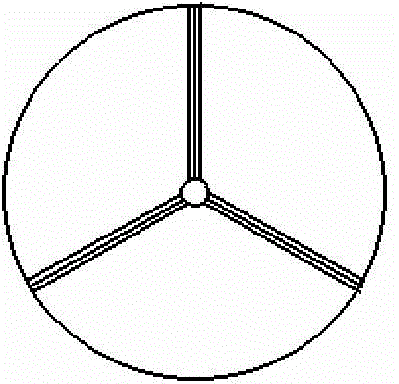

[0058] In this embodiment, the material basket 6 is divided into three blanching areas along the radial direction, such as figure 2 shown.

[0059] The method of blanching fresh lilies with vacuum-steam pulsating blanching equipment is as follows:

[0060] a. Turn on the steam generator 1 to make the absolute pressure of the steam generator 1 reach 0.4MPa;

[0061] b. Open the steam generator ball valve 3 and the steam solenoid valve 4, and pass steam into the blanching tank 13 for 2 minutes, so that the temperature of the blanching tank 13 rises to 80°C;

[0062] c. Remove the roots of fresh lilies (moisture content on a wet basis is about 71%), break off the pieces, clean, select lilies with bright white color, fresh and tender tissue, fresh and non-rotten, and the same size, and put them into the material basket 6;

[0063] d. Start the vacuum generation system, and when the vacuum degree in...

Embodiment 2

[0069] The grapes are blanched using vacuum-steam pulsating blanching equipment.

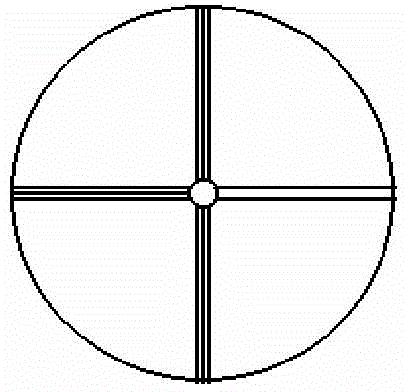

[0070] In this embodiment, the material basket 6 is divided into 4 blanching areas along the radial direction, such as image 3 shown.

[0071] The method of blanching grapes with vacuum-steam pulse type is as follows:

[0072] a. Turn on the steam generator 1 to make the absolute pressure of the steam generator 1 reach 0.4MPa;

[0073] b. Open the steam generator ball valve 3 and the steam solenoid valve 4, and pass steam into the blanching tank body 13 for 3 minutes, so that the temperature of the blanching tank body 13 rises to 90°C;

[0074] C, put a certain amount of seedless white grapes (about 79% moisture content in wet basis) through cleaning and drying into the basket 6;

[0075] d. Start the vacuum generation system, and when the vacuum degree in the blanching tank 13 reaches 0.01MPa, keep it for 15s;

[0076] e. Pass steam into the blanching tank body 13, and when the absolute pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com