High-low temperature circulating device for thermal cycle adsorption separation device

A high-low temperature cycle, adsorption and separation technology, applied in the field of thermonuclear fusion, can solve the problems of low efficiency and poor effect, and achieve the effect of increasing the speed of temperature change, improving the efficiency of heating and cooling, and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

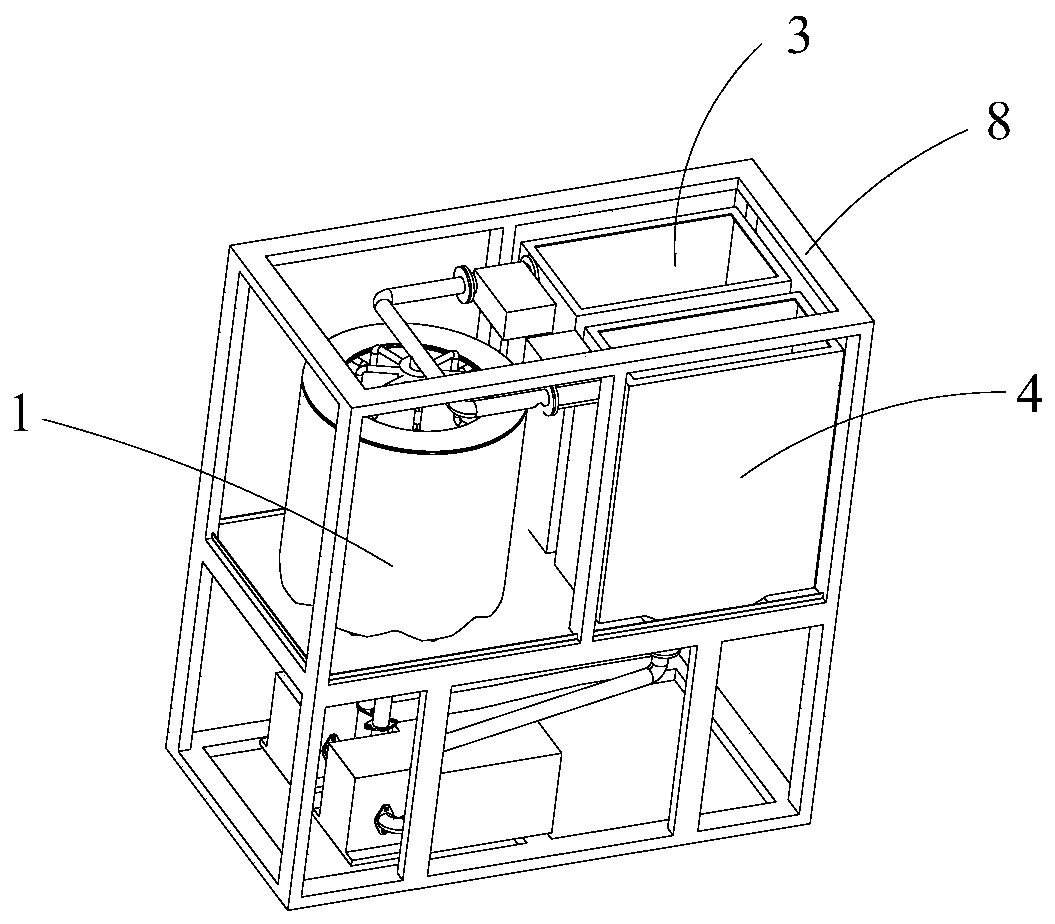

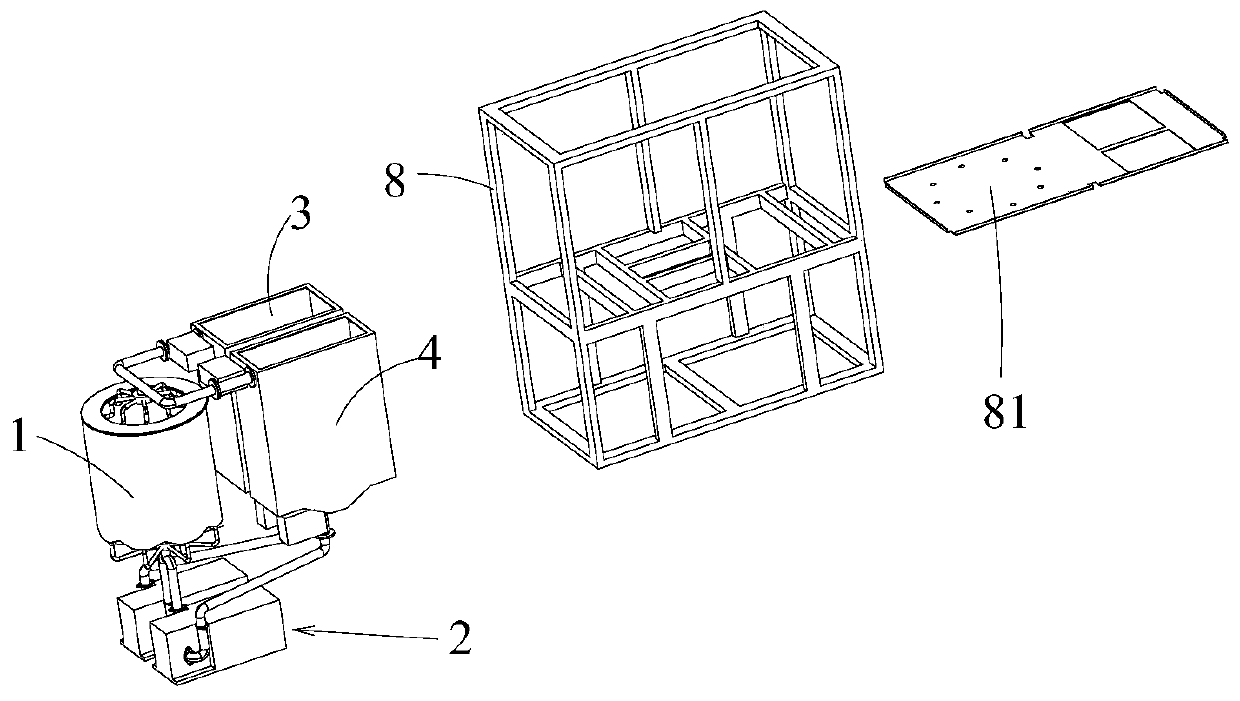

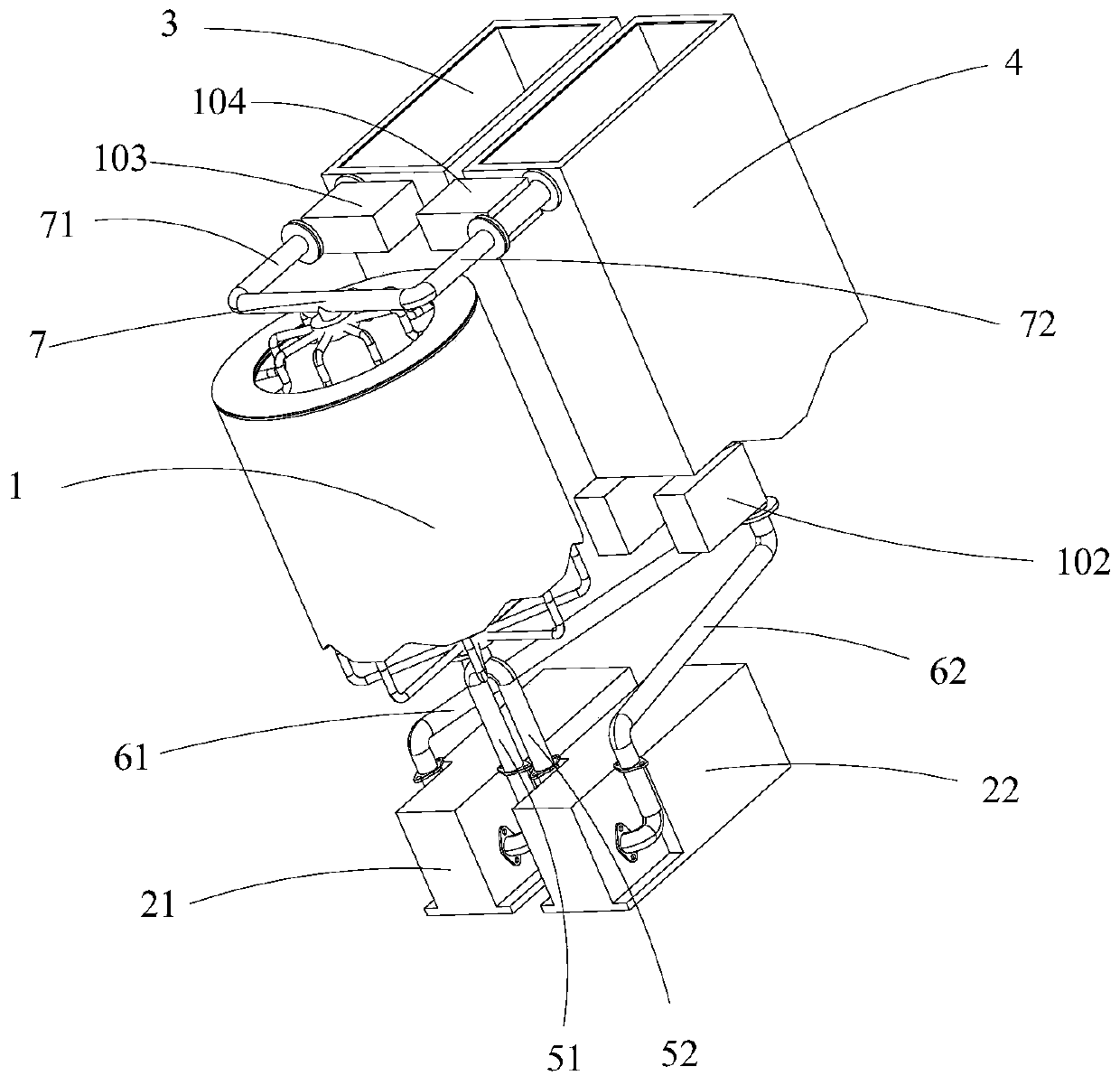

[0059] A high and low temperature cycle device for thermal cycle adsorption separation device, such as Figure 1-4 As shown, it includes an oil bath 1, an oil pump 2, a first oil tank 3 and a second oil tank 4; the oil bath 1 is used to accommodate a separation column, and the oil bath 1 is provided with an oil inlet and an oil outlet; The oil inlet of the oil bath 1 is arranged at the bottom of the oil bath 1 , and the oil outlet of the oil bath 1 is arranged at the top of the oil bath 1 .

[0060] The outlet of the oil pump 2 communicates with the oil inlet of the oil bath 1 through the oil inlet main pipe 5; the oil pump 2 includes a first oil pump 21 and a second oil pump 22; the oil inlet main pipe 5 includes a first oil inlet main pipe 51 and the second oil inlet supervisor 52;

[0061] The outlet of the first oil pump 21 communicates with the oil inlet of the oil bath 1 through the first oil inlet main pipe 51, and the inlet of the first oil pump 21 communicates with t...

Embodiment 2

[0079] Present embodiment improves oil bath 1 on the basis of embodiment 1, as Figure 5 , Figure 6 The oil bath 1 shown is in the shape of a hollow cylindrical ring. That is, the oil bath 1 includes a cylindrical outer wall 15, a cylindrical inner wall 16, an annular bottom wall 13 and an annular top wall 14; the upper and lower ends of the cylindrical outer wall 15 are respectively connected to the annular top wall 14 and the annular top wall The outer side of the annular bottom wall 13; the cylindrical inner wall 16 is located in the cylindrical outer wall 15, and the upper and lower ends of the cylindrical inner wall 16 are respectively connected to the annular top wall 14 and the annular bottom wall 13 inside.

[0080] Several oil inlet branch pipes 11 are arranged between the oil inlet main pipe 5 and the oil bath 1, and the several oil inlet branch pipes 11 are uniformly connected to the annular bottom wall 13 of the oil bath. Several oil outlet branch pipes 12 are ...

Embodiment 3

[0084] The difference between this embodiment and embodiment 1 is that, as Figure 8 As shown, the position of the first valve 101 and the second valve 102 is set to the common rear end of the first oil pump 21 and the second oil pump 22 , and the main valve 107 is set on the main oil pipe 5 . Through the control of multiple valves, the oil pump receives less heat and cold impact when it is not working, which can improve the service life of the oil pump and maintain the stability of the oil pump.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com