Copper-aluminum composite row caterpillar band drawing mold movable device

A technology of copper-aluminum composite row and mobile device, which is applied in the direction of wire drawing die, metal wire drawing, manufacturing tools, etc., to achieve the effect of stable material forming, small changes, and process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

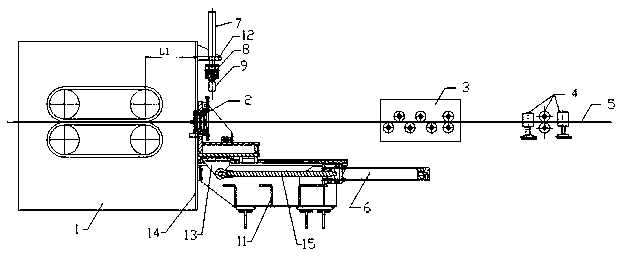

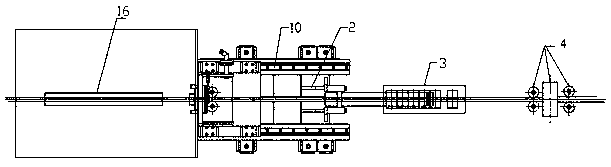

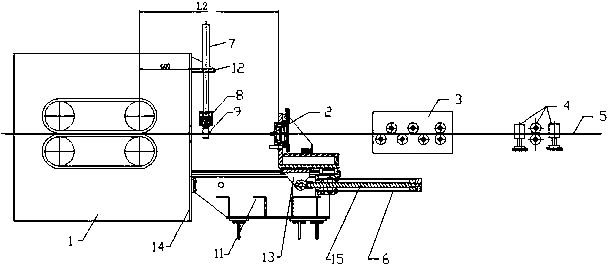

[0011] For a better understanding and implementation, the present invention will be further described below in conjunction with the accompanying drawings: the movable device of the copper-aluminum composite row crawler drawing mold includes a crawler puller 1, and a straightening device is arranged on the same horizontal line on the right side of the crawler puller 1. Straight machine 3 and incoming material guiding device 4, the right side of crawler belt drawing machine 1 is provided with drawing mold 2, and the bottom of drawing mold 2 is provided with mold support 11, and the front end of mold support 11 is fixed with frame 14 of crawler belt drawing machine 1 Connection, both sides above the mold support 11 are provided with slide rails 10, the lower end of the drawing die 2 is located in the slide rail 10, the drawing die 2 can slide back and forth along the slide rail 10, and the bottom of the drawing die 2 is provided with a connecting plate 13, connecting The plate 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com