Axle shaft sleeve production process

A production process and a technology for a half shaft casing, which is applied in the field of half shaft casing production technology, can solve the problems of low utilization rate of raw materials, large surplus material, etc., so as to improve the efficiency, reduce the generation of surplus material, and improve the utilization rate of raw materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

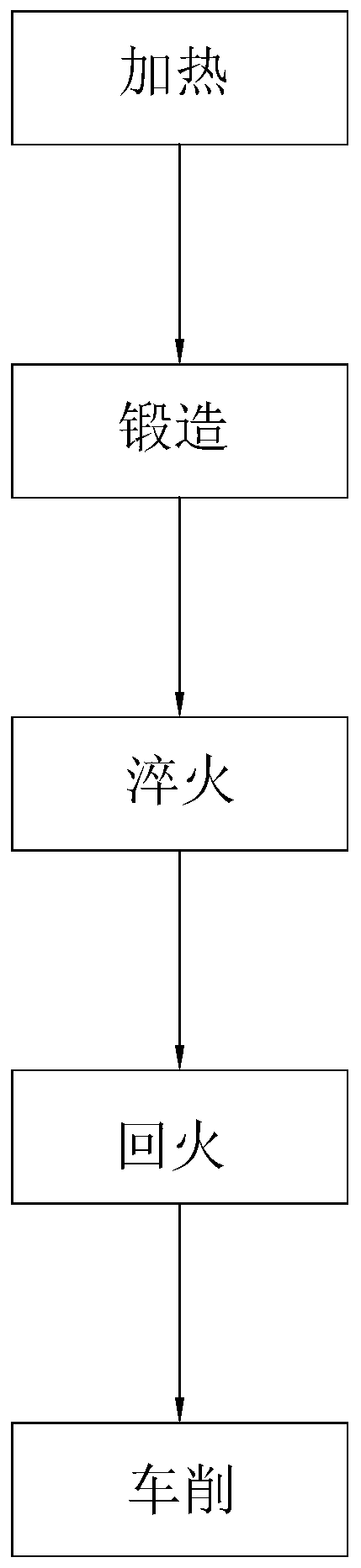

[0035] Example: such as figure 1 Shown, be a kind of semi-shaft casing production technique disclosed by the present invention, mainly comprise the following steps:

[0036] S1: Heating, choose seamless steel pipe blanks, use seamless steel pipes as raw materials for processing, no need to punch the blanks, and the seamless steel pipe itself has a central hole, thereby reducing the generation of residual materials and improving the utilization rate of raw materials. The blank is heated by a first heating furnace, which is an induction heating furnace. Because the induction heating furnace uses the electromagnetic induction effect to heat the billet, it will produce a skin effect. Skin effect means that when there is alternating current or alternating electromagnetic field in the conductor, the current distribution inside the conductor is uneven, and the current is concentrated in the "skin" part of the conductor, that is to say, the current is concentrated in the thin layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com