Preparation method of environment-friendly leather base cloth

A base fabric and leather technology is applied in the field of preparation of environmentally friendly leather base fabrics, which can solve the problems of affecting product feel, affecting product appearance, and being difficult to coat, and achieves the effects of uniform and suitable pressure, good hand feeling, and difficult coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of an environmentally friendly leather base cloth, comprising the following steps:

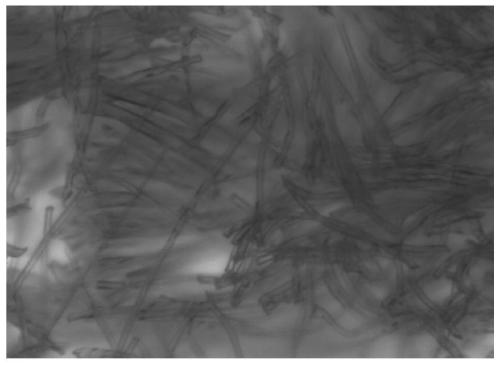

[0035] (1) being 0.2dtex with fineness, dispersing ultrafine and ultrashort polyester fibers with fiber length 5mm into deionized water, stirring evenly, to obtain polyester fiber solution;

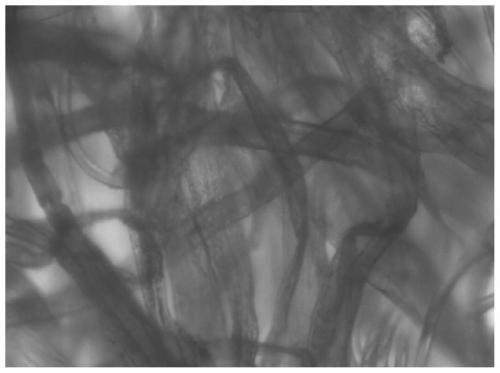

[0036] (2) Prepare polyester fiber woven base fabric on the unwinding rack, with a weight of 50g / m 2 , thickness 0.3mm, spare;

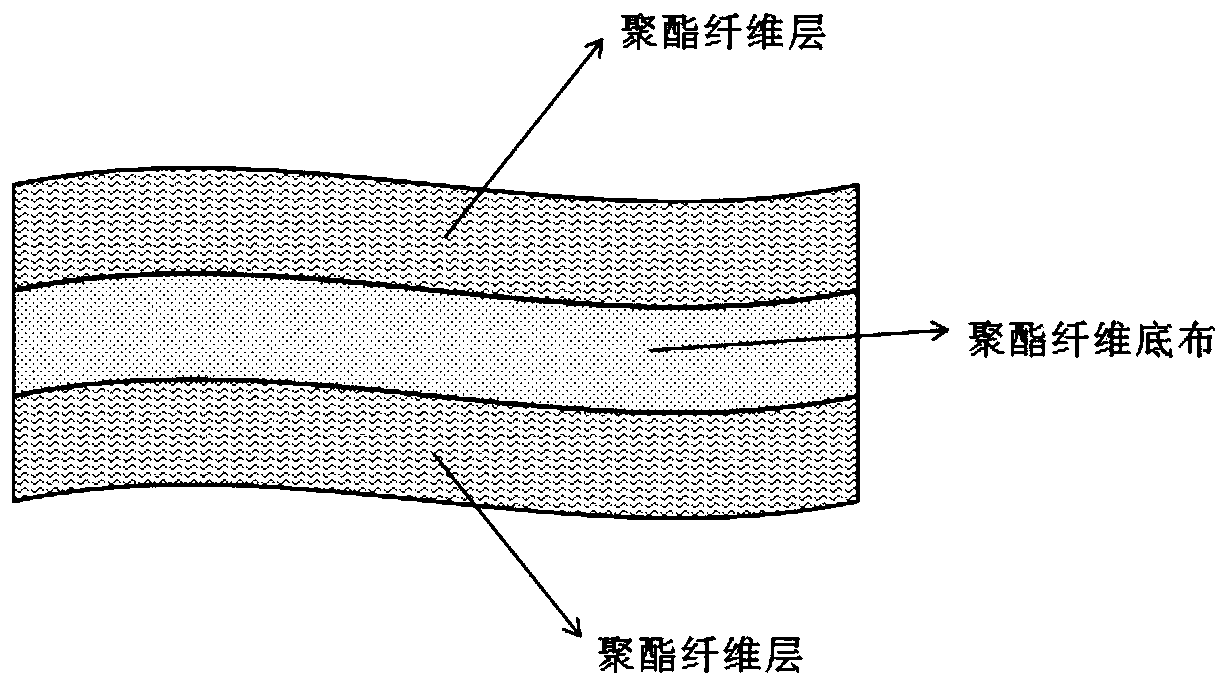

[0037] The polyester fiber solution in the step (1) is passed through a three-layer composite former to prepare two layers of polyester fiber layers, and the upper and lower two layers of polyester fiber layers are composited with the polyester fiber base cloth by 20kg pre-spunlace; The fiber base cloth is in the middle, and the two sides of the polyester fiber base cloth are polyester fiber layers, forming a three-layer composite leather base cloth;

[0038] (3) The three-layer composite leather base fabric is first reinforced with 40kg of ordinary...

Embodiment 2

[0041] A preparation method of an environmentally friendly leather base cloth, comprising the following steps:

[0042] (1) being 0.4dtex with fineness, dispersing ultra-fine and ultra-short polyester fibers with a fiber length of 6mm in deionized water, stirring evenly, to obtain a polyester fiber solution;

[0043] (2) Prepare polyester fiber woven base fabric on the unwinding rack, with a weight of 70g / m 2 , thickness 0.5mm, spare;

[0044]The polyester fiber solution in the step (1) is passed through a three-layer composite former to prepare two layers of polyester fiber layers, and the upper and lower two layers of polyester fiber layers are compounded with the polyester fiber base cloth by 30kg pre-spunlace; The fiber base cloth is in the middle, and the two sides of the polyester fiber base cloth are polyester fiber layers, forming a three-layer composite leather base cloth;

[0045] (3) The three-layer composite leather base fabric is first reinforced with 50kg of or...

Embodiment 3

[0047] A preparation method of an environmentally friendly leather base cloth, comprising the following steps:

[0048] (1) being 0.5dtex with fineness, dispersing the ultra-fine ultra-short polyester fiber of fiber length 7mm into deionized water, stirring evenly, obtaining polyester fiber solution;

[0049] (2) Prepare polyester fiber woven base fabric on the unwinding rack, with a weight of 100g / m 2 , thickness 0.7mm, spare;

[0050] The polyester fiber solution in the step (1) is passed through a three-layer composite former to prepare two layers of polyester fiber layers, and the upper and lower layers of polyester fiber layers are compounded with the polyester fiber base cloth by 40kg pre-spunlace; The fiber base cloth is in the middle, and the two sides of the polyester fiber base cloth are polyester fiber layers, forming a three-layer composite leather base cloth;

[0051] (3) The three-layer composite leather base fabric is first reinforced with 60kg of ordinary spu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com