A short-process processing method of imitation old and imitation linen yarn-dyed fabric

A processing method and a short-process technology, which is applied in the processing of textile materials, textiles, fabrics, etc., can solve the problem of uneven appearance of the distressed depth and depth, and achieve the effects of simple process, improved color fastness, and water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

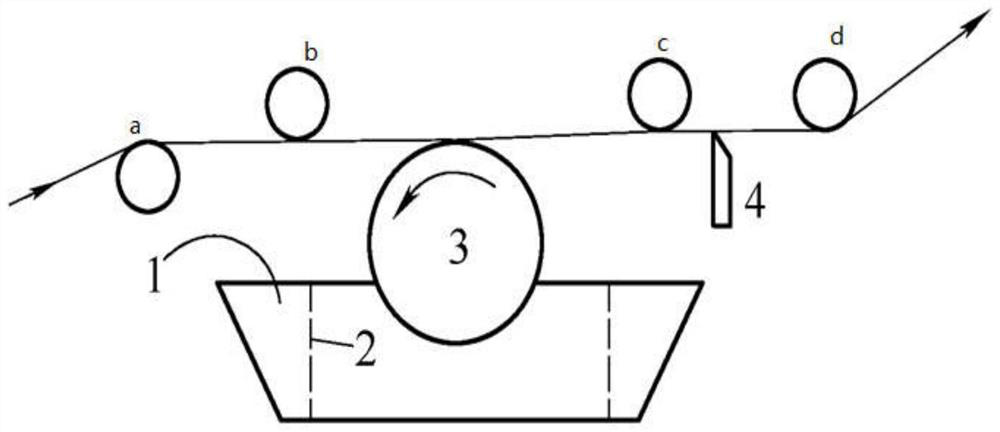

[0038] In the present invention, the 32S / 2 cotton double-strand blank thread is wound through a special yarn winding paint dyeing equipment, and the paint color paste is placed in a trough, and the pulp is fed through the rotation of the roller, and the cotton thread passes through the tape roller and passed through Control the tension of the cotton thread and the rate of color paste on the cotton thread to control the depth of the color. More than 800 threads can be dyed at one time. Carry out yarn-dyed weaving, bleach the yarn-dyed fabric with chlorine, rinse off the uncrosslinked paint on the surface, and then bake it at 160 degrees to make the paint adhered to the yarn crosslinked and improve the color fastness.

[0039] The technological process of the present invention is as follows: putting on the thread bobbin→sizing and dyeing→pre-baking→topping the warp beam→weaving→rinsing and aging→baking and finalizing.

[0040] 1. The specifications of the raw materials are as fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com