Weather-proof ink-absorbing decorative film base material and application thereof

A technology for decorative films and substrates, applied in the field of decorative materials, can solve the problem that the clarity of graphics and ink fastness need to be further improved, the weather resistance and high temperature resistance need to be further improved, and the graphics and text clarity and firmness of the printed layer need not be improved. It can achieve the effect of high promotion and application value, good comprehensive performance and performance stability, high graphic and text clarity and firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

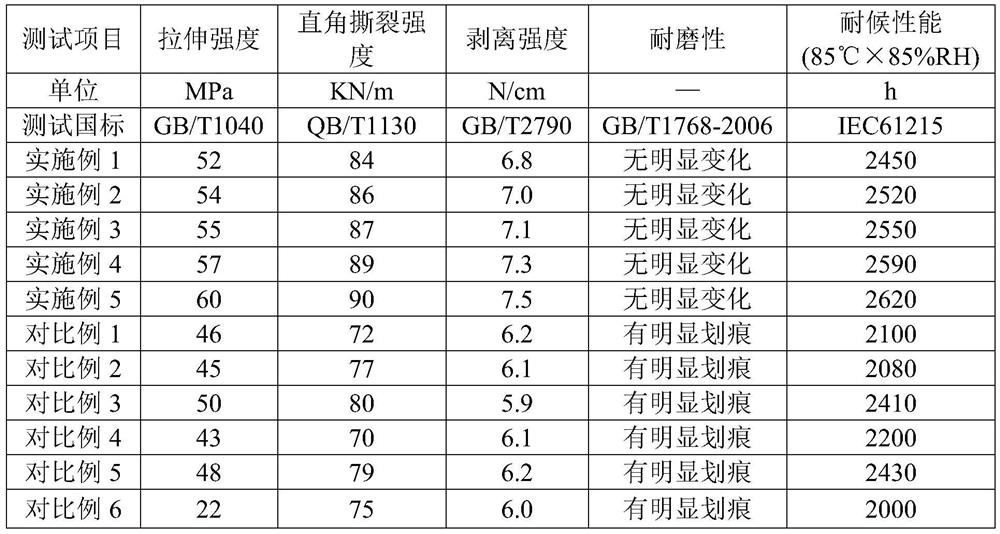

Examples

Embodiment 1

[0024] A decorative film material is characterized in that it includes a weather-resistant protective layer, a printing layer and a substrate layer from top to bottom; the printing layer is formed by printing a layer of oil paint on the substrate layer by a printing machine; the The above-mentioned weather-resistant protective layer and the printing layer are laminated by an adhesive layer; the described weather-resistant protective layer is made of the following raw materials in parts by weight: di[(S)-[(5S)-5-vinyl-1- Azabicyclo[2.2.2]octane-7-yl]-(6-methoxyquinolin-4-yl)methyl]carbonate 20 parts, phenyl vinyl sulfone 10 parts, allyl succinyl 10 parts of imino carbonate, 10 parts of 1-allyl-2-trifluoromethylbenzimidazole, 5 parts of anisole, 10 parts of 1-cyano-2-propenyl acetate, 3,3, 7,7,10,10-hexaphenyl-2,4,6,8,9,11-hexaoxa-1,5-disarsena-3,7,10-trisilabicyclo[3.3.3 ] 1 part of undecane, 0.01 part of benzoin, 30 parts of methylene chloride; the adhesive is polyacrylic aci...

Embodiment 2

[0030] A decorative film material is characterized in that it includes a weather-resistant protective layer, a printing layer and a substrate layer from top to bottom; the printing layer is formed by printing a layer of oil paint on the substrate layer by a printing machine; the The weather-resistant protective layer and the printing layer are laminated by polyurethane adhesive; the weather-resistant protective layer is made of the following raw materials in parts by weight: di[(S)-[(5S)-5-vinyl-1 -Azabicyclo[2.2.2]octane-7-yl]-(6-methoxyquinolin-4-yl)methyl]carbonate 23 parts, phenyl vinyl sulfone 12 parts, allyl succinate 12 parts of imidocarbonate, 12 parts of 1-allyl-2-trifluoromethylbenzimidazole, 6.5 parts of anisole, 12 parts of 1-cyano-2-propenyl acetate, 3,3 ,7,7,10,10-hexaphenyl-2,4,6,8,9,11-hexaoxa-1,5-disarsa-3,7,10-trisilabicyclo[3.3. 3] 1.5 parts of undecane, 0.015 parts of benzoin ethyl ether, and 33 parts of tetrahydrofuran.

[0031] The preparation method of...

Embodiment 3

[0036] A decorative film material is characterized in that it includes a weather-resistant protective layer, a printing layer and a substrate layer from top to bottom; the printing layer is formed by printing a layer of oil paint on the substrate layer by a printing machine; the The above-mentioned weather-resistant protective layer and the printing layer are laminated by an adhesive layer; the described weather-resistant protective layer is made of the following raw materials in parts by weight: di[(S)-[(5S)-5-vinyl-1- Azabicyclo[2.2.2]octane-7-yl]-(6-methoxyquinolin-4-yl)methyl]carbonate 25 parts, phenyl vinyl sulfone 15 parts, allyl succinyl 13 parts of iminocarbonate, 15 parts of 1-allyl-2-trifluoromethylbenzimidazole, 8 parts of anisole, 13 parts of 1-cyano-2-propenyl acetate, 3,3, 7,7,10,10-hexaphenyl-2,4,6,8,9,11-hexaoxa-1,5-disarsena-3,7,10-trisilabicyclo[3.3.3 ] 2 parts of undecane, 0.02 parts of 2-hydroxy-2-methyl-1-phenylacetone, 35 parts of acetone; the adhesive i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com