Online punching and flavoring device and method for natural cigar coating machine-made cigar

A wrapper and mechanism technology, which is applied in the field of natural wrapper mechanism cigar rolling equipment, can solve the problems of wrapper damage, failure to add flavor to cigars, and inability to meet the diversified needs of customers, and achieve low cost, suitable moisture, and high-quality products. The effect of style personalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

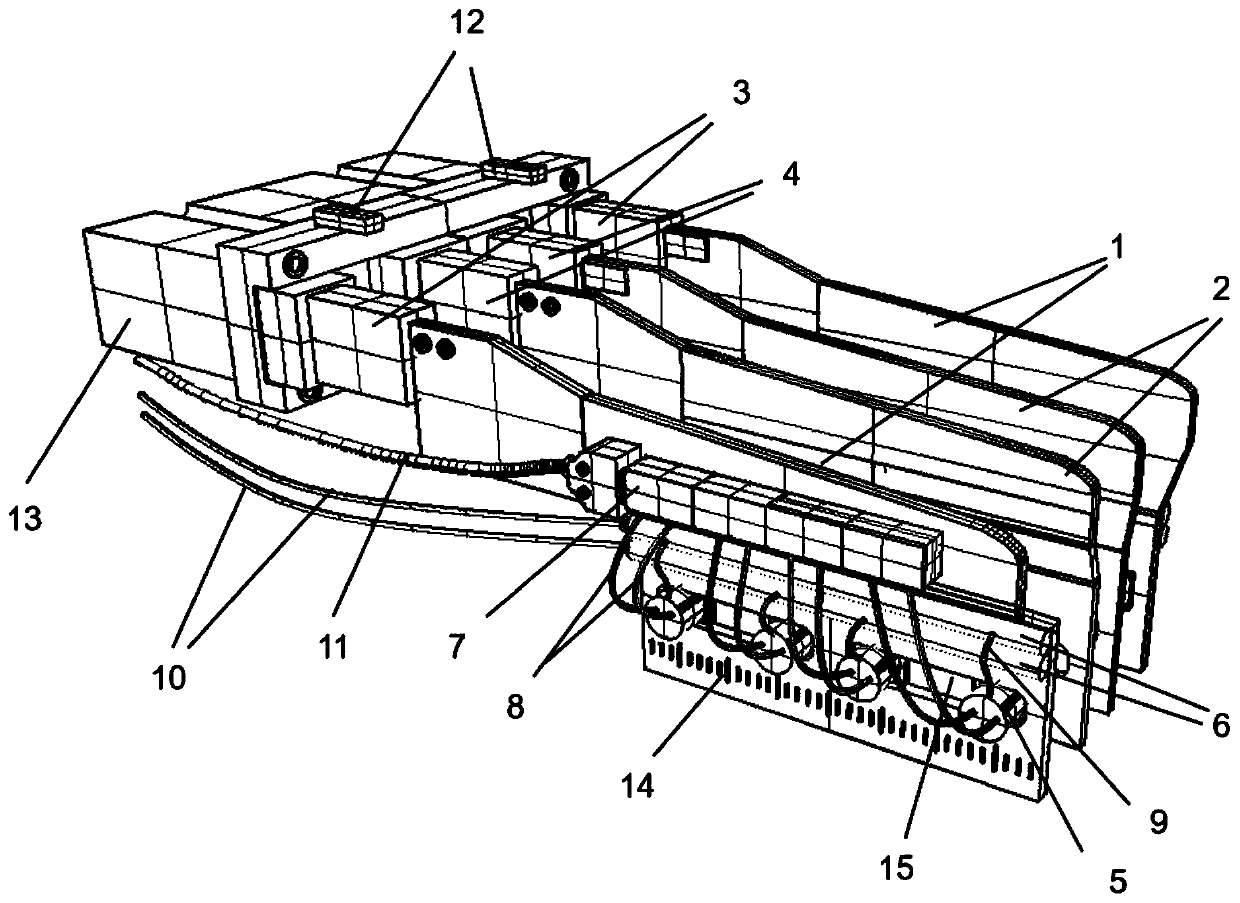

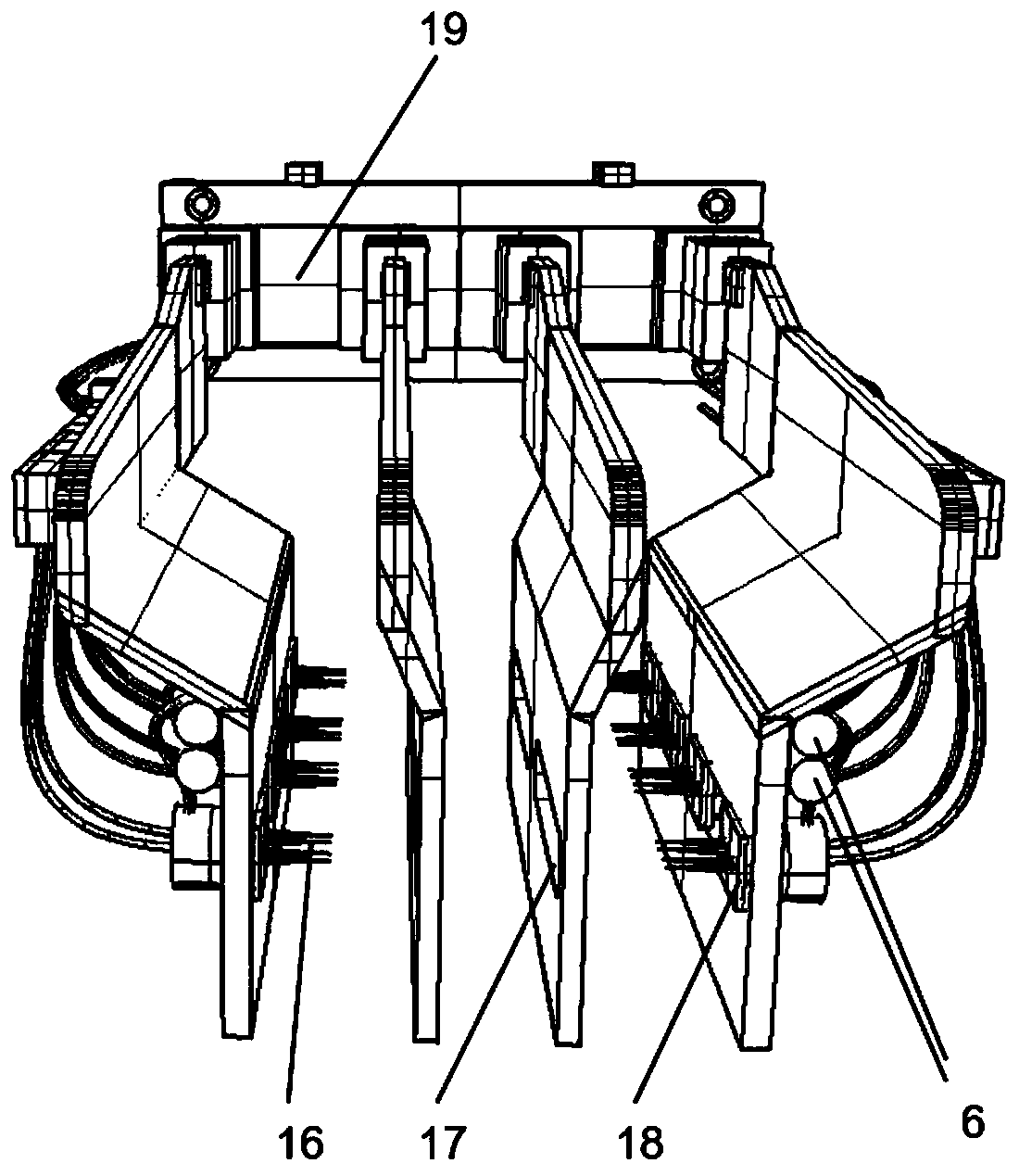

[0037] Example 1, see Figure 1-2 :

[0038] An online punching and flavoring device for cigars with a natural wrapper mechanism, including two outer clips 1, two inner clips 2, two outer pneumatic fingers 3, two inner pneumatic fingers 4, a cylinder 13, a valve island 7, Feed liquid cylinder 5, feed liquid diversion bin 6, PLC control system, positioning detection device 12, needle plate 18 and hollow perforating perfuming needle 16.

[0039] The outer clip 1 is fixed on the outer pneumatic finger 3, the inner clip 2 is fixed on the inner pneumatic finger 4, the inner clip 2 is located inside the outer clip 1, the outer pneumatic finger 3 and the inner pneumatic finger 4 are on the sliding seat on the cylinder 19 slides horizontally, the inside clip 2 is provided with a strip pinhole 17, the strip pinhole 17 is parallel to the inside clip 2, and the outside clip 1 is provided with a chute 15, and the chute 15 and the strip pinhole 17 Correspondingly, the needle plate 18 can...

Embodiment 2

[0047] Embodiment 2: This device can also perform quantitative flavoring through a peristaltic pump. The specific flavoring process is as follows: an online punching and flavoring device for cigars with a natural wrapper mechanism, including two outer clips 1 and two inner clips 2. Two outer pneumatic fingers 3, two inner pneumatic fingers 4, cylinder 13, material-liquid diversion bin, peristaltic pump, PLC control system, needle plate 18 and hollow perforating needle 16.

[0048] The outer clip 1 is fixed on the outer pneumatic finger 3, the inner clip 2 is fixed on the inner pneumatic finger 4, the inner clip 2 is located inside the outer clip 1, the outer pneumatic finger 3 and the inner pneumatic finger 4 are on the sliding seat on the cylinder 19 slides horizontally, the inside clip 2 is provided with a strip pinhole 17, the strip pinhole 17 is parallel to the inside clip 2, and the outside clip 1 is provided with a chute 15, and the chute 15 and the strip pinhole 17 Corr...

Embodiment 3

[0052] Example 3, see Figure 1-2 A method for perforating and flavoring cigars with a natural wrapper mechanism online, the steps are as follows:

[0053] Step 1: Rotate the mechanical arm so that the strip-shaped pinhole 17 on the inner clip is parallel to the side of the cigarette, and the inner pneumatic finger 4 controls the inner clip 2 to clamp the side of the cigarette;

[0054] Step 2: The outer pneumatic finger 3 controls the outer clip 1 to move closer. When the positioning detection device 12 detects that the outer pneumatic finger 3 is displaced to the set position, the PLC control system controls the outer pneumatic finger 3 to stop running. At this time, the position of the outer clip 1 The hollow perforating and flavoring needle 16 passes through the strip-shaped pinhole 17 to complete the side punching of the cigarette;

[0055] Step 3: The PLC control system controls the valve island 7, and sends out a pneumatic signal to drive the feed liquid cylinder 5, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com